Get In Touch +1 (888) 575-2099

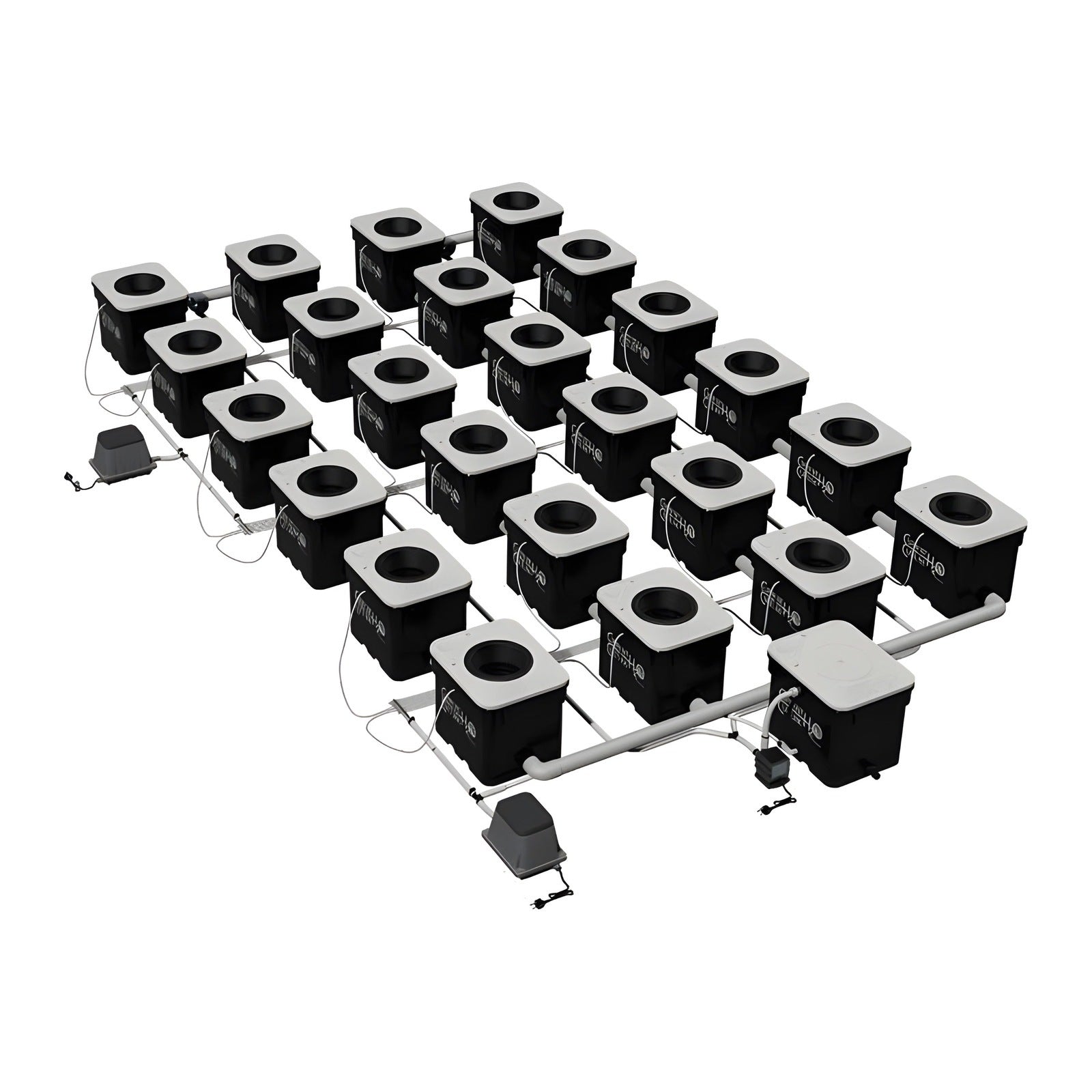

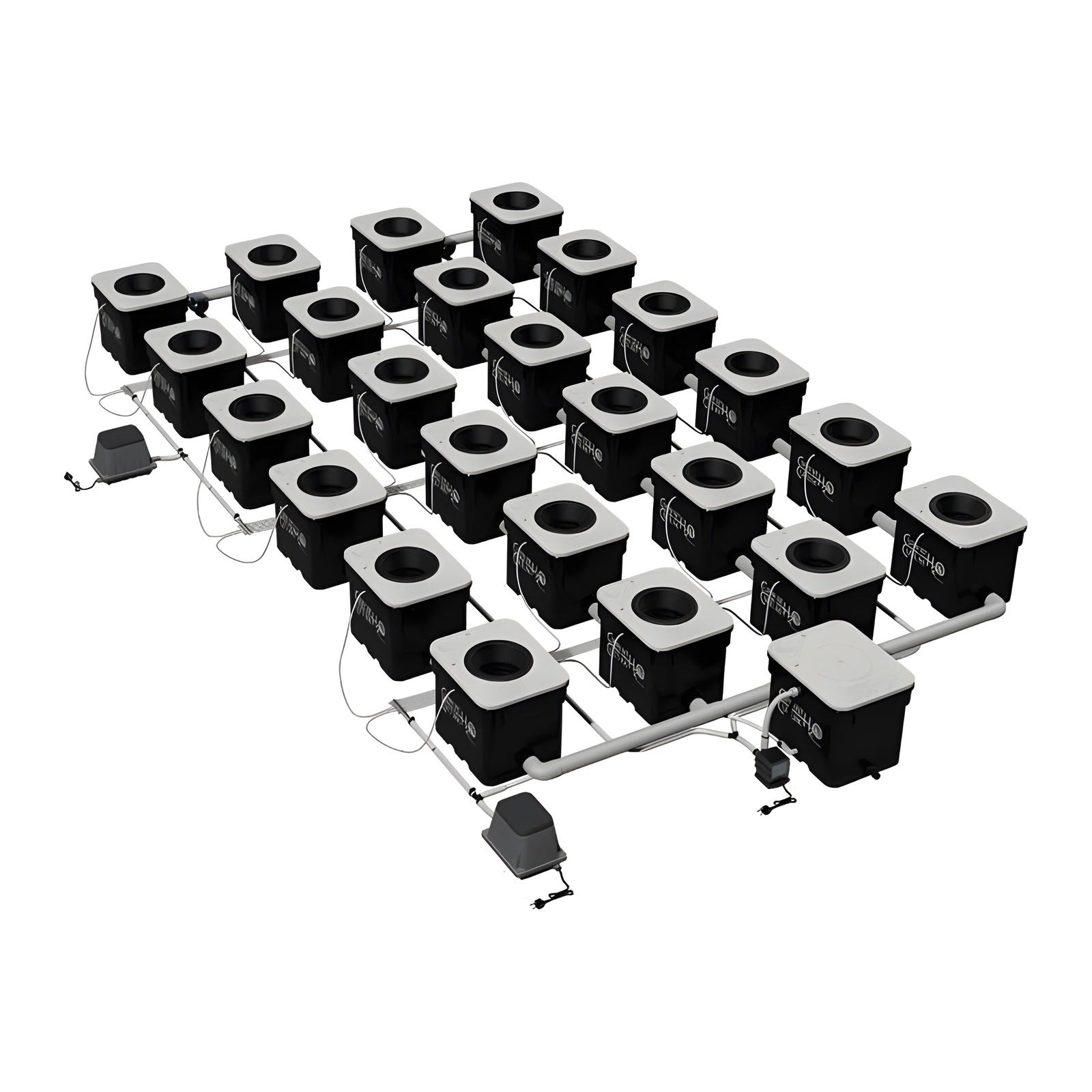

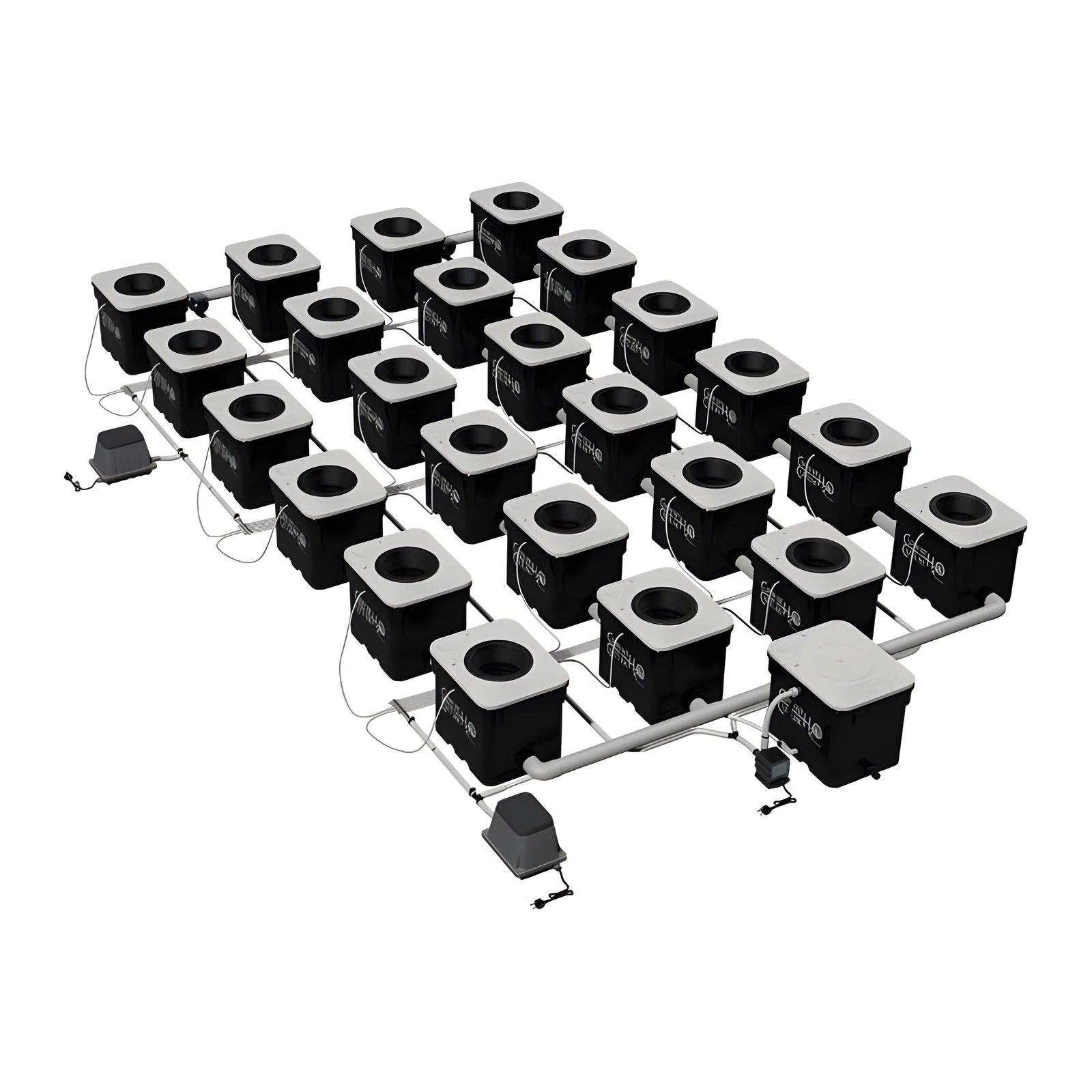

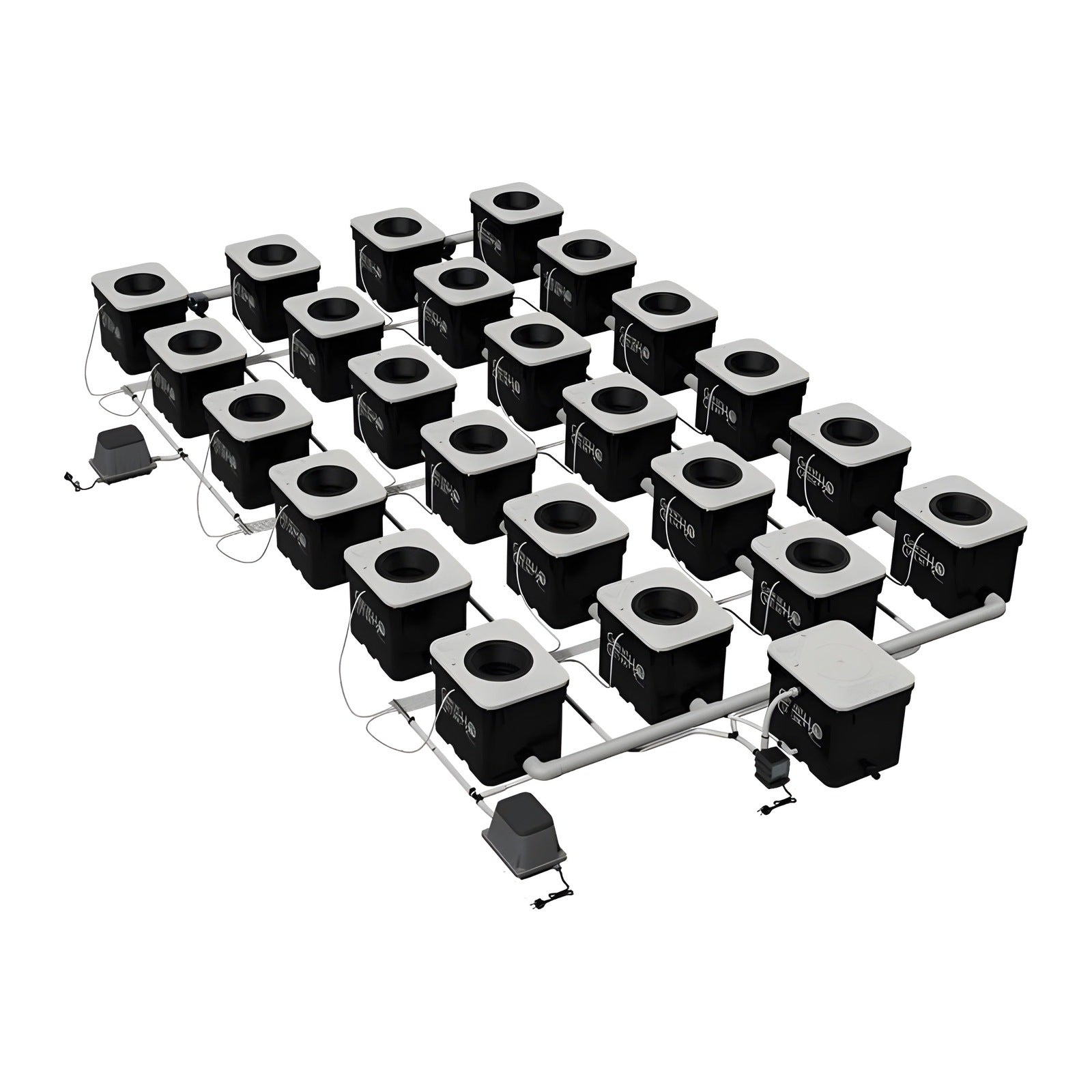

Current Culture H2O Under Current Double Barrel 24 XL

- $5,241.95

$5,241.95- $5,241.95

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Current Culture H2O Under Current Double Barrel 24 XL

Step into the future of hydroponics with the Under Current® System, featuring the revolutionary Sub-Current Culture® (SCC) technology. Unleash the power of negative water pressure to create hyper-aerobic conditions, supercharging nutrient solutions and fueling explosive plant growth. With constant 24/7 circulation, your plants experience uniform pH and EC levels, ensuring consistent performance and awe-inspiring yields.

Crafted with a modular design, the Under Current® System offers versatility and ease of use. Choose from multiple growth module sizes and plant spacing options, with over 60 system configurations available to suit any size grow space. Premium construction using high-quality commercial components ensures durability and reliability, backed by our commitment to innovation and excellence.

Features

-

Sub-Current Culture® Technology: Provides superior aeration and nutrient for explosive growth.

-

Modular Design: Easy to set up, expand, and customize for any grow space.

-

Premium Construction: Built with high-quality, commercial-grade components.

-

Increased Efficiency: Optimizes nutrient uptake and reduces water usage.

-

Reduced Maintenance: Easy to maintain with consistent pH and EC levels.

-

Expert Grower Support: Dedicated team to help you achieve success.

Specifications

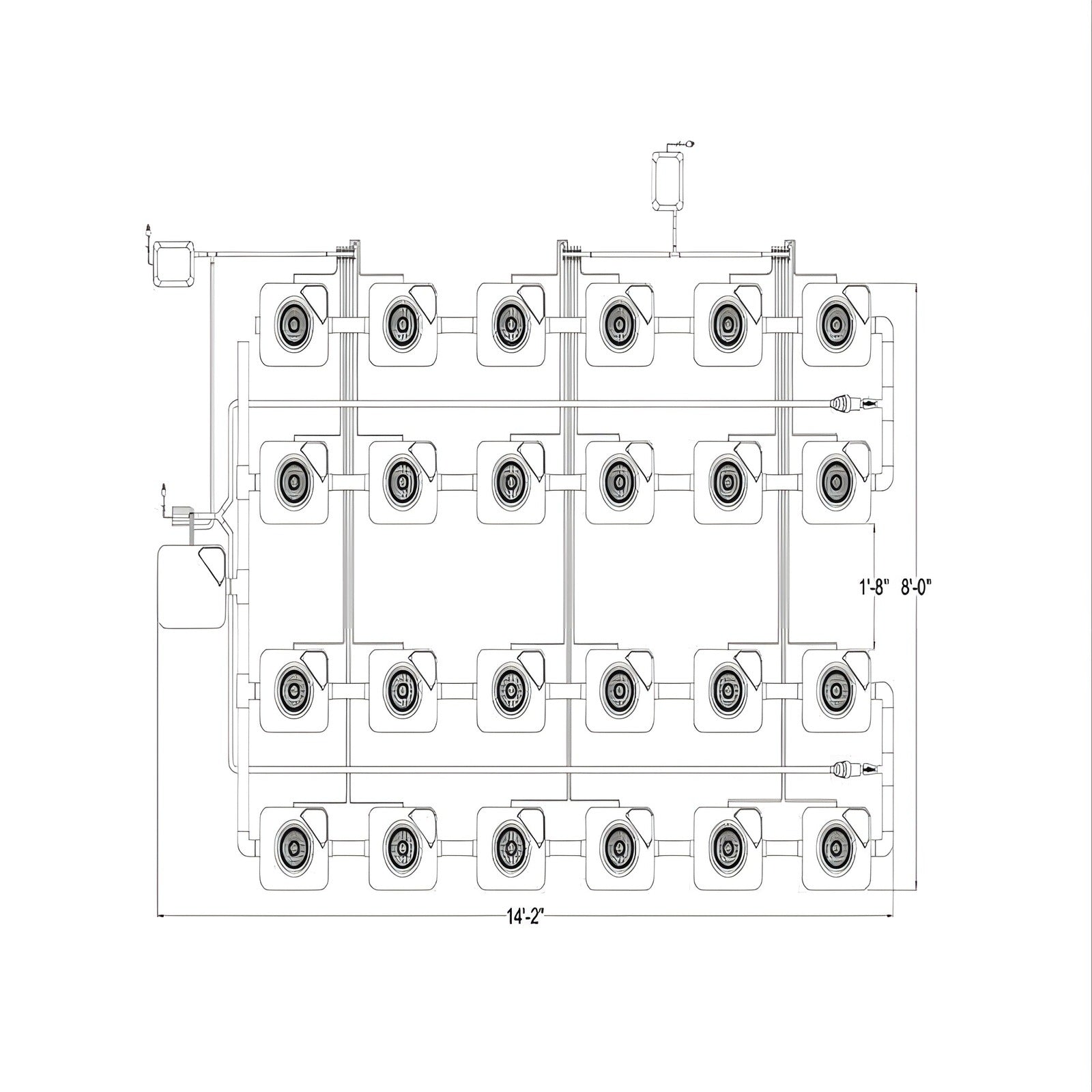

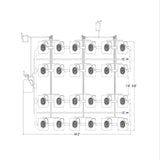

| SYSTEM FOOTPRINT (FEET / METERS) | 8’2" x 13’9" / 2.5m x 4.2m |

|---|---|

| TOTAL SYSTEM VOLUME (GALLONS / LITERS) | 175 / 663 |

| POWER USAGE (WATTS) | 280 |

| AIR PUMP SIZE(S) (LPM) | (1)80, (1)80 [Epi+10,14] |

| AERATION RATE (LPM PER GALLON) | 0.91 |

| WATER PUMP SIZE (GPH / LPH) | 1200 / 4543 |

| RECIRCULATION RATE (EXCHANGES PER HR.) | 6.86 |

| SHIPPING WEIGHT (LBS. / KG) | 230 / 104.3 |

| SHIPPING BOX SIZES (IN.) | (2)16x18x48, (2)16x18x36 |

The Under Current Double Barrel 24 XL Includes

-

8 Gallon “Blackout Series” Growth Modules

-

CCH2O 5.5″ Heavy Duty Lids with Port Hole

-

CCH2O 5.5″ Heavy Duty Net Pots

-

2″ Manifold & Joints with 2” UC Spin-Tight Bulkheads

-

Danner Mag-Drive™ Return Pump

-

Premium Linear Air Pump(s)

-

9” Air Diffuser Disc

-

Aqua-Pore Air Diffusers

-

Air Distribution Manifold

-

Air Hose, In-Line Filter(s)

-

Adjustable Float Valve with Reservoir Adapter Kit

-

Drain Valve

-

Chiller Adapter

-

Garden Hose Drain Adapter

-

Cultured Solutions™ VEG A/B

-

1-Year Warranty.

What Our Experts Think

- Optimal Water Flow: The Double Barrel XL design ensures superior water circulation, promoting balanced nutrient distribution for healthier and more vigorous plant growth.

- Spacious Capacity: With the XL size, this system provides ample space for larger plants or multiple crops, increasing overall yield potential.

- Built for Durability: Constructed with high-quality materials, the system is designed to withstand continuous use in demanding hydroponic environments.

- Customizable Performance: Offers adjustable flow options, enabling you to fine-tune the system to meet the specific needs of your plants for optimal growth.

- Effortless Maintenance: The system is easy to clean and maintain, ensuring long-term efficiency and consistent performance.

Q&A

Q: What is the Current Culture H2O Under Current Double Barrel 24 XL?

A: The Current Culture H2O Under Current Double Barrel 24 XL is a high-performance hydroponic system designed for large-scale, commercial growers, featuring a dual-barrel design for optimal nutrient and oxygen delivery to plants.

Q: What are its key features?

A: It offers a dual-barrel setup for efficient nutrient circulation, durable PVC construction, and advanced aeration for healthy root systems. The system is easy to assemble and scalable for various commercial growing operations.

Q: What is the system's size and capacity?

A: The Double Barrel 24 XL measures 24 feet in length, providing ample space for a large number of plants, ideal for maximizing yield in high-density, commercial hydroponic cultivation.

Q: What is it ideal for?

A: Ideal for commercial hydroponic growers, it is perfect for cultivating high-value crops, optimizing space, and ensuring efficient nutrient and water delivery.

Q: Does it meet industry standards?

A: Yes, the Double Barrel 24 XL meets professional hydroponic standards, ensuring reliable performance, high yield, and optimal plant growth for commercial applications.

Maintenance Tips

- Clean After Every Grow Cycle: Thoroughly clean the system to remove nutrient buildup, salt deposits, and algae. Use a mild, pH-neutral cleaner for best results.

- Monitor Water Quality: Regularly check pH levels, nutrient concentration, and water temperature to ensure they are within optimal ranges for plant growth.

- Inspect Tubing and Pipes: Check for blockages, leaks, or wear in the pipes and tubing. Clean or replace components as needed to maintain smooth water flow.

- Maintain Pumps and Aeration: Regularly inspect and clean pumps, air stones, and other aeration components to ensure proper oxygenation and circulation. Replace damaged parts when needed.

- Clean Reservoirs: Periodically clean the nutrient reservoirs to prevent contamination, algae growth, and debris buildup.

- Check System Components: Routinely inspect valves, fittings, and connections for any signs of wear, cracks, or leaks. Replace any damaged components immediately.

- Annual Deep Clean: Perform an in-depth clean and thorough inspection of the system at least once a year to maintain its long-term performance and efficiency.

Related Products

- Choosing a selection results in a full page refresh.