Get In Touch +1 (888) 575-2099

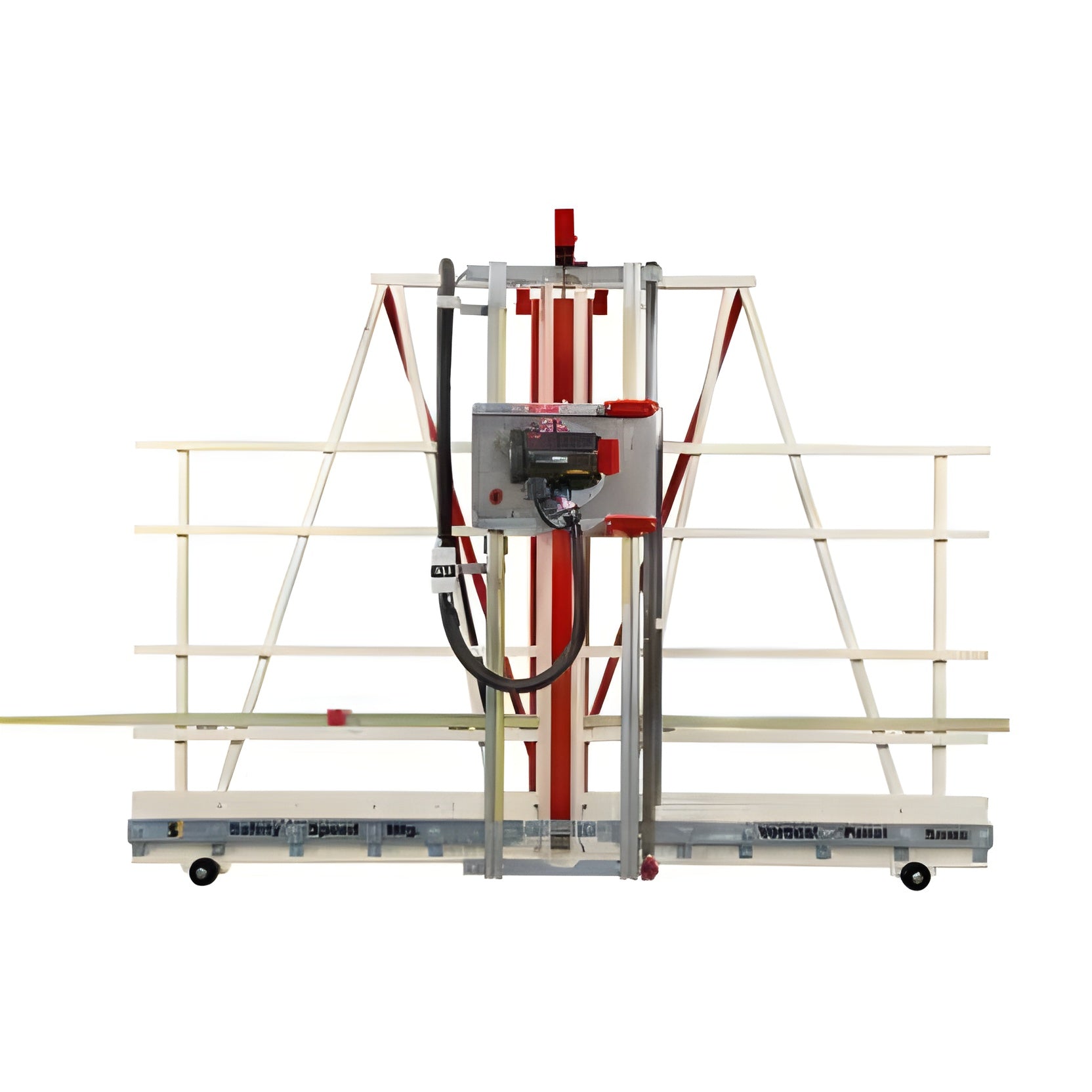

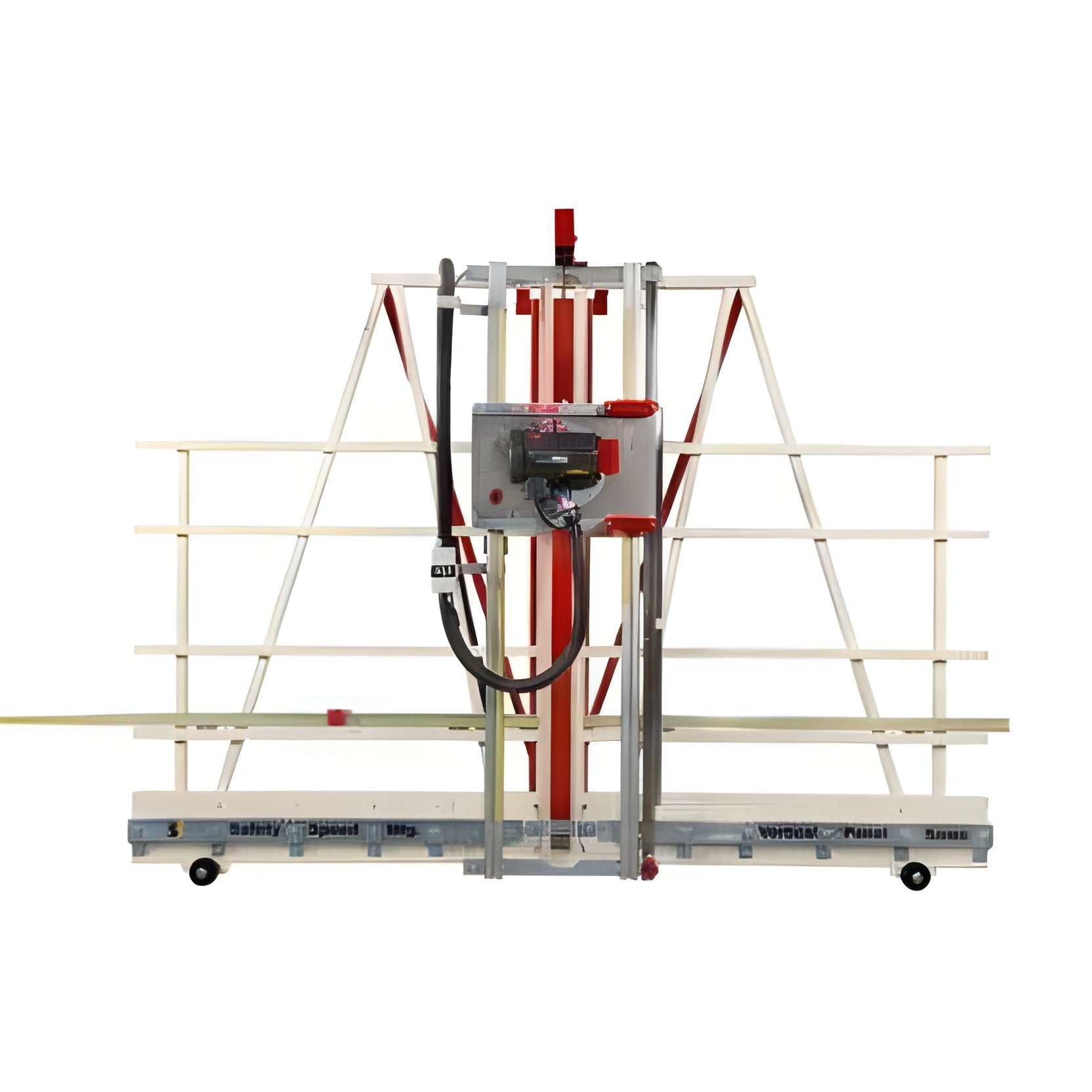

Safety Speed 7000 Panel Saw

- $10,199.00

$13,768.00- $10,199.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Safety Speed 7000 Panel Saw

The model 7000 is the latest entry into our high capacity machine lineup. Meant for continuous production, the 7000 Panel Saw cuts within 1/64″ straight and square and up to 2″ deep. Pick from three different motor configurations.

Features

- Three different high induction saw motor configurations

- Heavy-Duty welded steel frame

- Low voltage switch protection

- Saw blade

- Vertical and horizontal rulers

- Quick change from vertical to horizontal cutting

- Integrated stand

- Solid aluminum rollers

- Dust collection ready

- Hold down bar

- Enclosed counterweight

- Quick stop gauges with stop block

- Floating pressure saw foot

- Wheels

- 3 year warranty

Specifications

| Weight | 950 lbs |

|---|---|

| Dimensions | 124 × 42 × 95 in |

| Max. Crosscut |

64'/1625mm |

| Max. Rip Cut |

Unlimited |

| Cut Depth |

2'/50mm |

| Cut Accuracy |

1/64'/.4mm |

| Frame Length |

120'/3050mm |

| Daily Usage |

Continuous (8+ Hours) |

| Rollers |

14 |

| Saw Blade Diameter |

8'/210mm |

| Motor |

2HP, 1~ 230V, 3HP, 3~ 230V, 3HP, 3~ 460V |

| Shipping Weight |

670 lbs/304 kg |

Documents

Product manual

Product parts

7000 Panel Saw Sheet

What Our Experts Think

- Accurate Cutting: The Safety Speed 7000 Panel Saw is engineered to provide precise, smooth cuts on a variety of materials, making it perfect for high-quality woodworking and cabinetry.

- Heavy-Duty Construction: Built for industrial use, the 7000 model is designed with robust materials to endure the demands of busy workshops, ensuring long-lasting durability.

- Ease of Use: The machine features intuitive controls, allowing for easy setup and operation, which helps improve productivity and reduce training time.

- Versatile Capabilities: Ideal for cutting plywood, MDF, particle board, and other sheet materials, providing flexibility for various woodworking applications.

- Space-Efficient Design: Compact yet powerful, the 7000 panel saw is a great option for shops with limited space, offering large cutting capacity in a smaller footprint.

- Safety Features: Includes integrated safety features like protective guards, ensuring the well-being of the operator during use.

Q&A

Q: What is the Safety Speed 7000 Panel Saw?

A: The 7000 is a professional-grade panel saw designed for precise cutting of large panels, ideal for woodworking, cabinetry, and other high-accuracy applications.

Q: What are the key features of the 7000 Panel Saw?

A: It features a heavy-duty frame, adjustable cutting depth, a powerful motor, and a precision sliding table for smooth, accurate cuts on various materials.

Q: What materials can the 7000 Panel Saw cut?

A: The 7000 can cut wood, plywood, MDF, particleboard, and laminates, making it versatile for different woodworking and cabinetry projects.

Q: How does the sliding table improve the cutting process?

A: The sliding table offers smooth, controlled movement for large panels, increasing cutting accuracy and reducing operator effort, especially for long or heavy sheets.

Q: Is the 7000 Panel Saw suitable for high-volume production?

A: Yes, the 7000 is built for heavy-duty, high-volume use, making it an excellent choice for professional woodworking shops with continuous cutting needs.

Q: What safety features are included with the 7000?

A: The saw includes protective guards, safety switches, and an emergency stop function to ensure safe operation for the user.

Maintenance Tips

-

Clean After Each Use: Wipe down the saw blade, work area, and rails to remove sawdust and debris. Use a soft cloth, air compressor, or vacuum system to clean the equipment thoroughly.

-

Inspect and Replace Saw Blade: Regularly check the saw blade for dullness, chips, or wear. Replace or sharpen the blade when necessary to ensure smooth, precise cuts and prevent unnecessary strain on the motor.

-

Lubricate Moving Parts: Lubricate the rails, guide tracks, and carriage system periodically to reduce friction and ensure smooth operation. Use the manufacturer-recommended lubricants.

-

Check and Tighten Fasteners: Inspect and tighten all screws, bolts, and fasteners regularly to prevent vibrations or misalignment during operation. Ensure proper alignment to maintain cutting accuracy.

-

Check the Carriage and Alignment: Inspect the carriage system for smooth operation. Make sure the carriage moves freely along the rails and adjust as needed to keep the system properly aligned.

-

Dust Collection Maintenance: Inspect and clean the dust collection system to remove blockages and ensure it is working effectively. Clean the hoses, filters, and other components to maintain optimal airflow and dust extraction.

-

Inspect Electrical Components: Regularly check wiring, switches, and electrical connections for signs of wear or damage. Ensure all electrical components are securely connected and functioning correctly.

-

Test Safety Features: Verify that all safety features, including blade guards, emergency stops, and safety switches, are in good working order and free from obstructions.

Related Products

- Choosing a selection results in a full page refresh.