Get In Touch +1 (888) 575-2099

Safety Speed 72GP Edgebander, Glue Pot

- $11,999.00

$14,768.00- $11,999.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

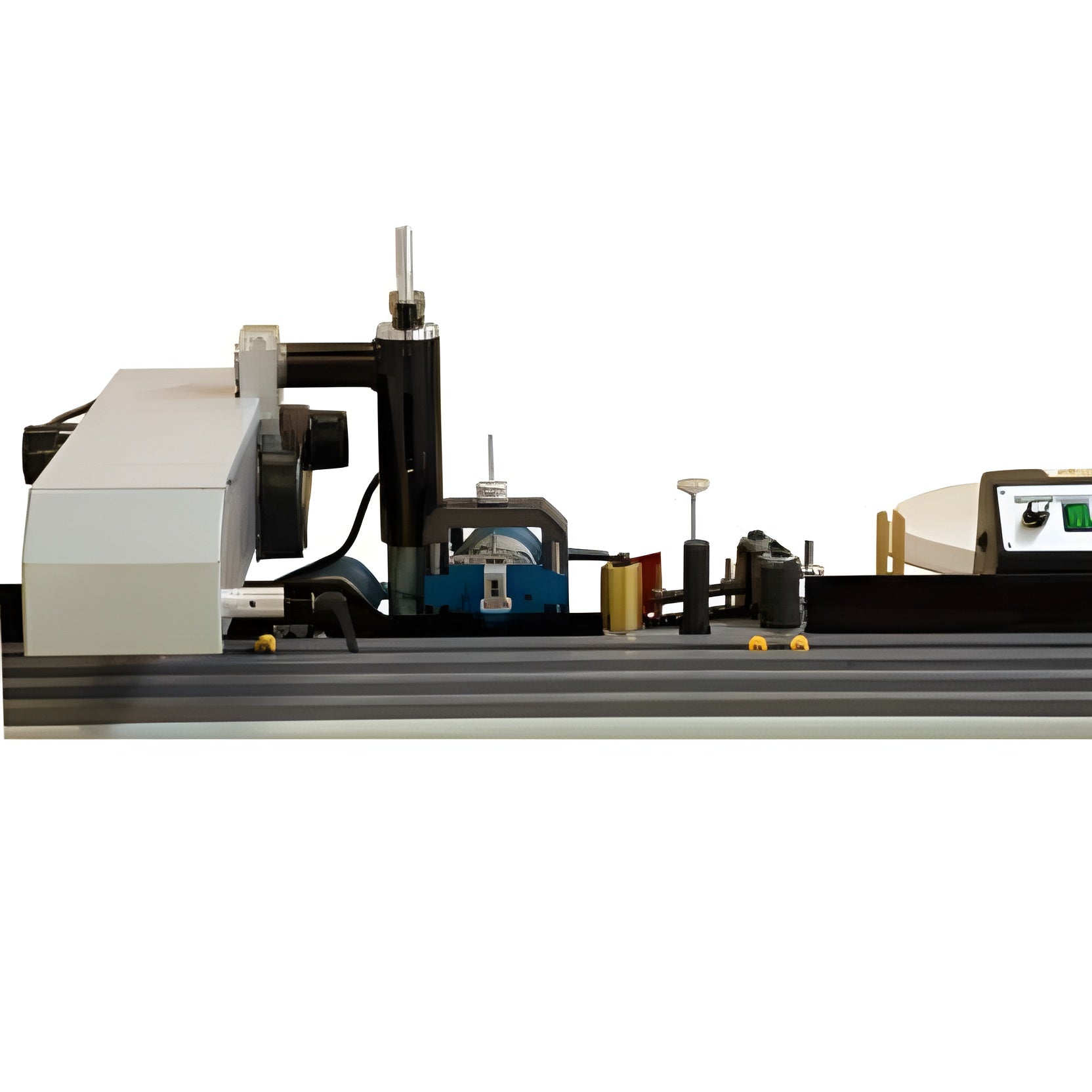

Safety Speed 72GP Edgebander, Glue Pot

The Glue Pot Edgebander applies glue to your panel, before edgebanding it and trimming it at up to 24 feet per minute. Engineered with a temperature controlled Glue Pot, the 72GP prevents glue from overheating or splattering. The 72GP Edgebander is the ideal solution for smaller woodworking shops currently edgebanding inefficiently or doing it by hand. Two industrial routers and knives provide trimming and minimizes the need to sand or file edges from material.

This dependable glue pot machine with adjustable glue extrusion performs similar to other units costing thousands of dollars more. The price and performance of this machine makes it the perfect choice for the small to medium sized woodworking shop.

Product demonstration

Removing from Crate and Setup

Features

- Digital P.I.D. temperature control to reduce glue overheating and burning with standby temperature mode.

- Micro adjust tape guide makes changing tape widths fast and simple.

- Electromagnetic end cutters means no need for compressed air supply.

Dust collection outlet reduces trimmings - Easy to set-up, operate, and maintain.

Anodized glue pot interior for ease of cleaning. - Built in safety control to prevent glue spindle motor from being turned on before glue is melted.

- Short 10-12 minute glue heat up time.

- Accutrim edge trim system uses industrial duty trim router motors ensuring a quality finish.

- Automatic conveyor for consistent feed rate.

- Solid edge flush trimming and edge molding capability.

- Machined billet aluminum components.

- American made with 3 year warrant

Specifications

| Weight | 540 lbs |

|---|---|

| Dimensions | 80 × 28 × 52 in |

| Dimensions (Shop) |

72'L x 48'H x 37'D |

| Power Supply |

220V, 20 amp, 1~ |

| Tape Types |

Polyester/PVC/Wood/Single Laminate Strips |

| Tape Widths |

1/2'/13mm to 1 3/4'/45mm |

| Min. Panel Length |

6' |

| Min. Panel Width |

3 1/2' |

| Max Tape Thickness |

1mm |

| Max Feed Rate |

24 FPM |

Documents

Product manual

Product parts

72GP Edgebander Specifications

What Our Experts Think

- Precision Edgebanding: The Safety Speed 72GP Edgebander with Glue Pot is designed to provide high-quality, consistent edgebanding for woodworking applications, ensuring a professional finish on every project.

- Efficient Glue Pot System: The integrated glue pot ensures a smooth, uniform application of glue, improving adhesion and reducing waste, making the process quicker and more efficient.

- Heavy-Duty Construction: Built with industrial-grade materials, this edgebander is made for durability and long-term use in high-volume production environments.

- User-Friendly Operation: Simple controls allow for easy setup and adjustment, reducing downtime and enabling operators to quickly switch between tasks.

- Versatility: Works with a variety of edge materials, including wood, PVC, and melamine, making it ideal for a broad range of woodworking projects.

- Improved Productivity: By streamlining the edgebanding process, this machine helps speed up production, ensuring high-quality results in less time.

Q&A

Q: What is the Safety Speed 72GP Edgebander with Glue Pot?

A: The Safety Speed 72GP Edgebander is a high-quality machine designed to apply edge banding to panels, featuring a glue pot system for smooth and precise adhesive application on various materials.

Q: What are the key features of the 72GP Edgebander?

A: This edgebander includes an automatic glue pot, adjustable feed speed, precise edge banding application, and robust construction for durability in high-production environments.

Q: What materials can the 72GP Edgebander handle?

A: The 72GP can handle wood, MDF, plywood, and laminate materials, making it ideal for cabinetry, furniture manufacturing, and other woodworking projects.

Q: How does the glue pot work on the 72GP?

A: The glue pot heats and applies the adhesive evenly to the edge of the panels, ensuring a strong bond for the edge banding material, resulting in clean, professional finishes.

Q: Is this edgebander suitable for heavy-duty use?

A: Yes, the 72GP is designed for industrial use, capable of handling high-volume production with consistent, high-quality results.

Q: What safety features are included with the 72GP Edgebander?

A: The edgebander includes safety guards, emergency stop functions, and user-friendly controls to ensure safe operation during use.

Maintenance Tips

-

Clean After Each Use: Remove glue residue, dust, and debris from the glue pot, feed rollers, and other components. Use a soft cloth or a non-abrasive cleaner. Pay special attention to the glue pot area to prevent dried glue buildup.

-

Glue Pot Maintenance: Regularly clean the glue pot and heating elements to prevent glue from hardening. Use the manufacturer's recommended solvents and cleaning tools to remove excess glue.

-

Inspect Nozzles and Glue Feed System: Check glue nozzles for clogs and clean them thoroughly. Ensure the glue feed system is free of blockages to guarantee consistent glue application.

-

Lubricate Moving Parts: Lubricate feed rollers, chains, and other moving parts as per the manufacturer's guidelines to reduce friction and keep parts running smoothly.

-

Check Belt and Feed System: Inspect belts for wear, proper tension, and alignment. Replace or adjust if needed to ensure smooth material feeding.

-

Monitor Glue Pot Temperature: Regularly check the temperature of the glue pot to make sure it stays within the recommended range. Ensure the thermostat is calibrated correctly for optimal glue flow.

-

Inspect Electrical and Heating Elements: Check for proper function of electrical components and heating elements. Ensure that all electrical connections are secure and free of wear.

-

Dust Collection System: Keep the dust collection system clean and free of blockages to maintain proper airflow and efficiency. Clean or replace filters as needed.

Related Products

- Choosing a selection results in a full page refresh.