Get In Touch +1 (888) 575-2099

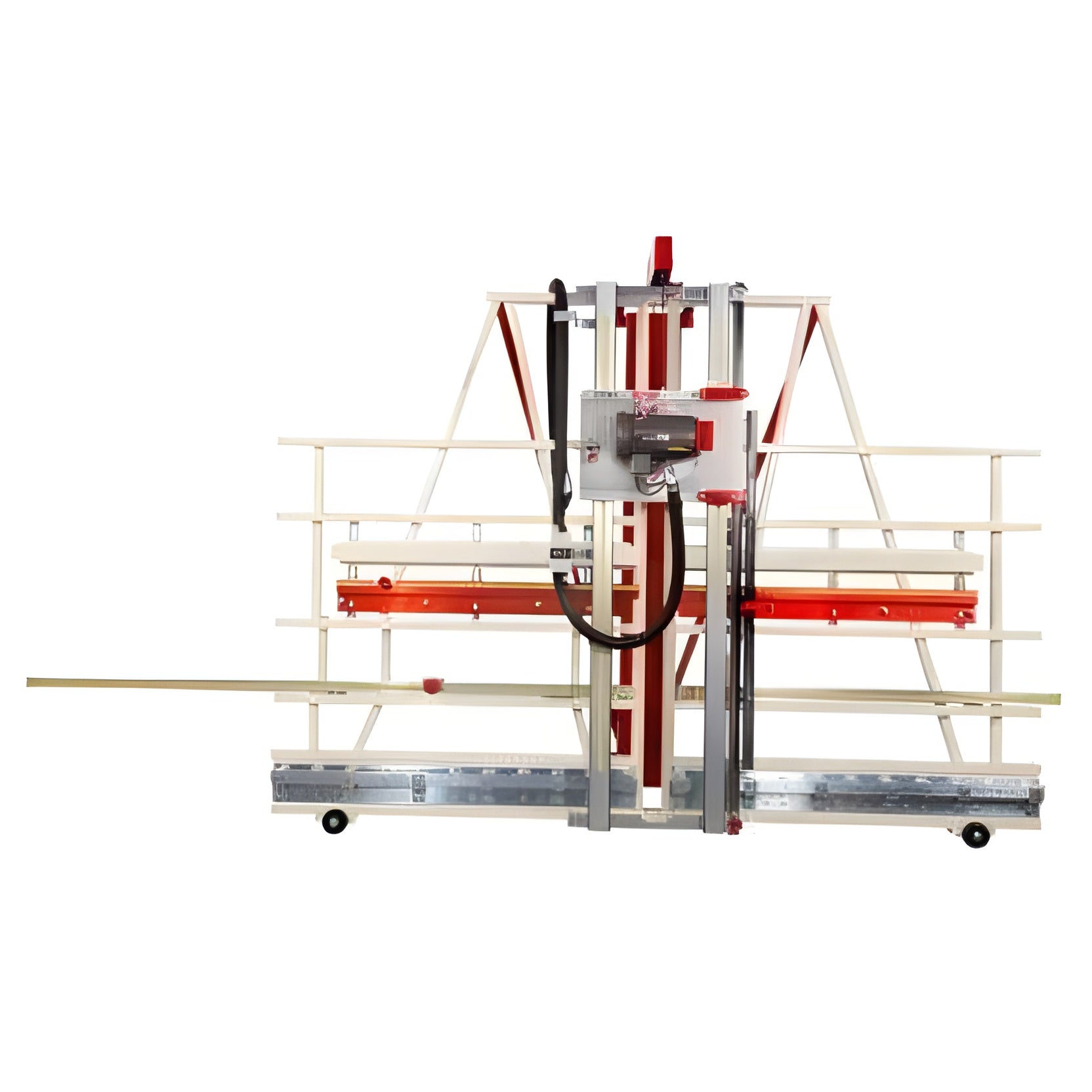

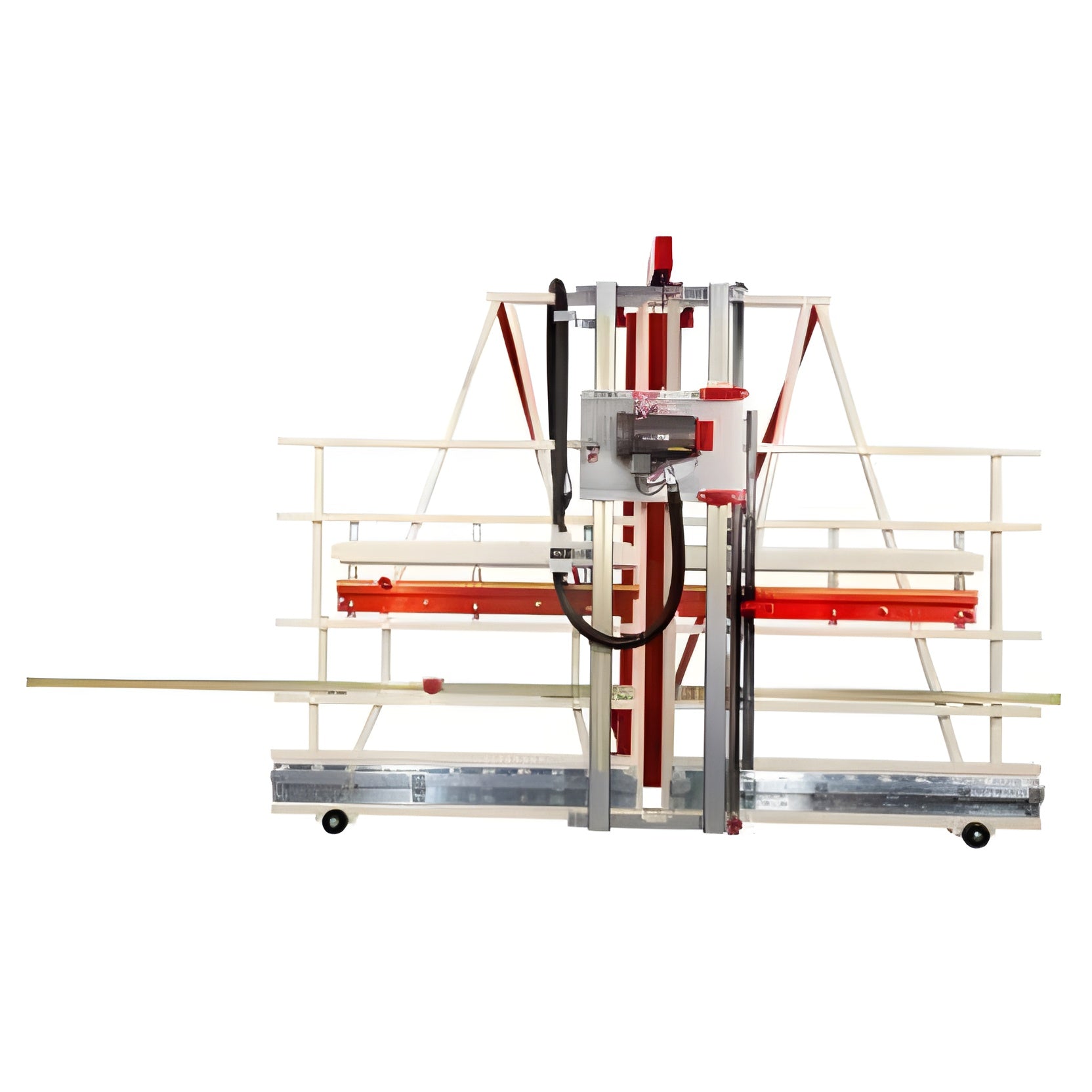

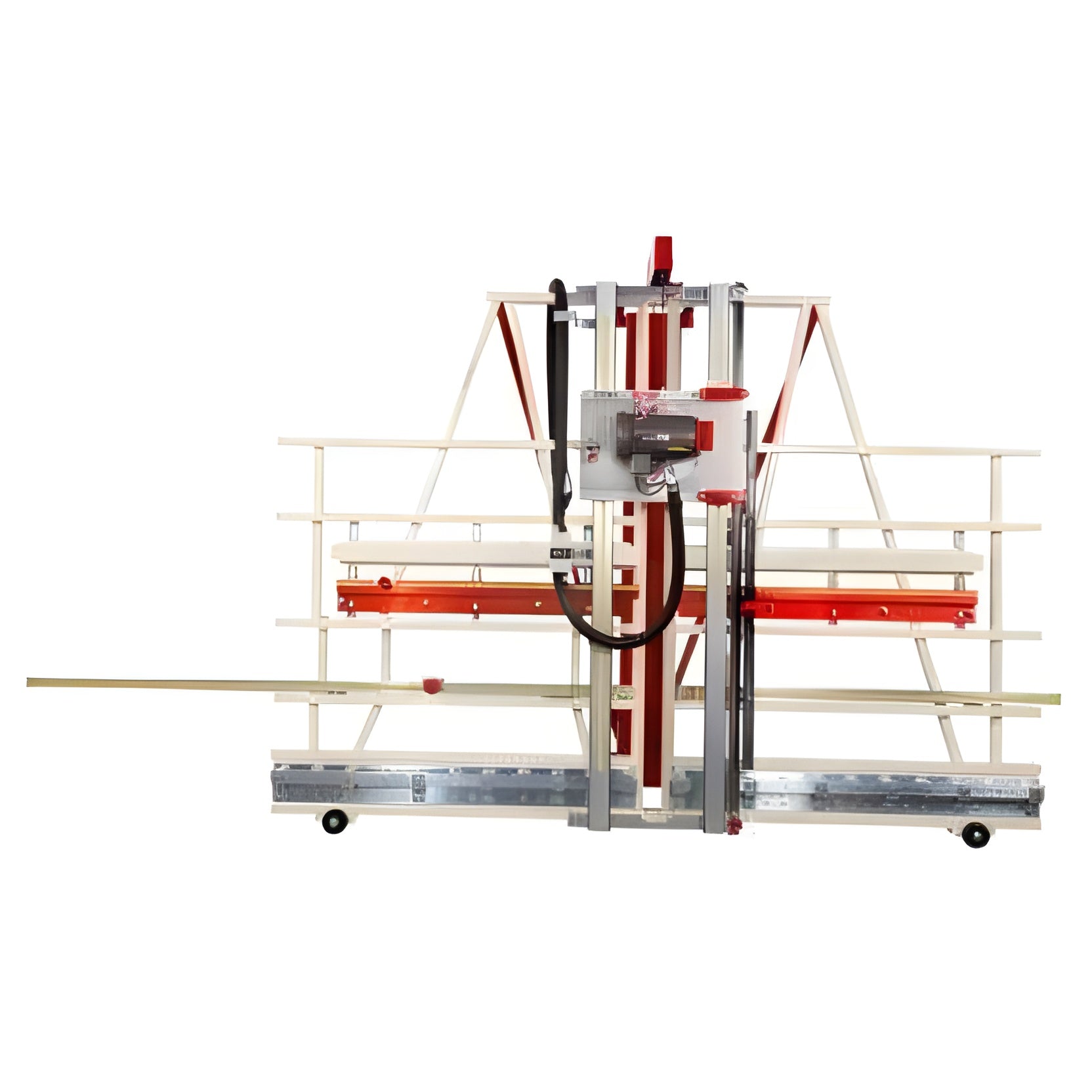

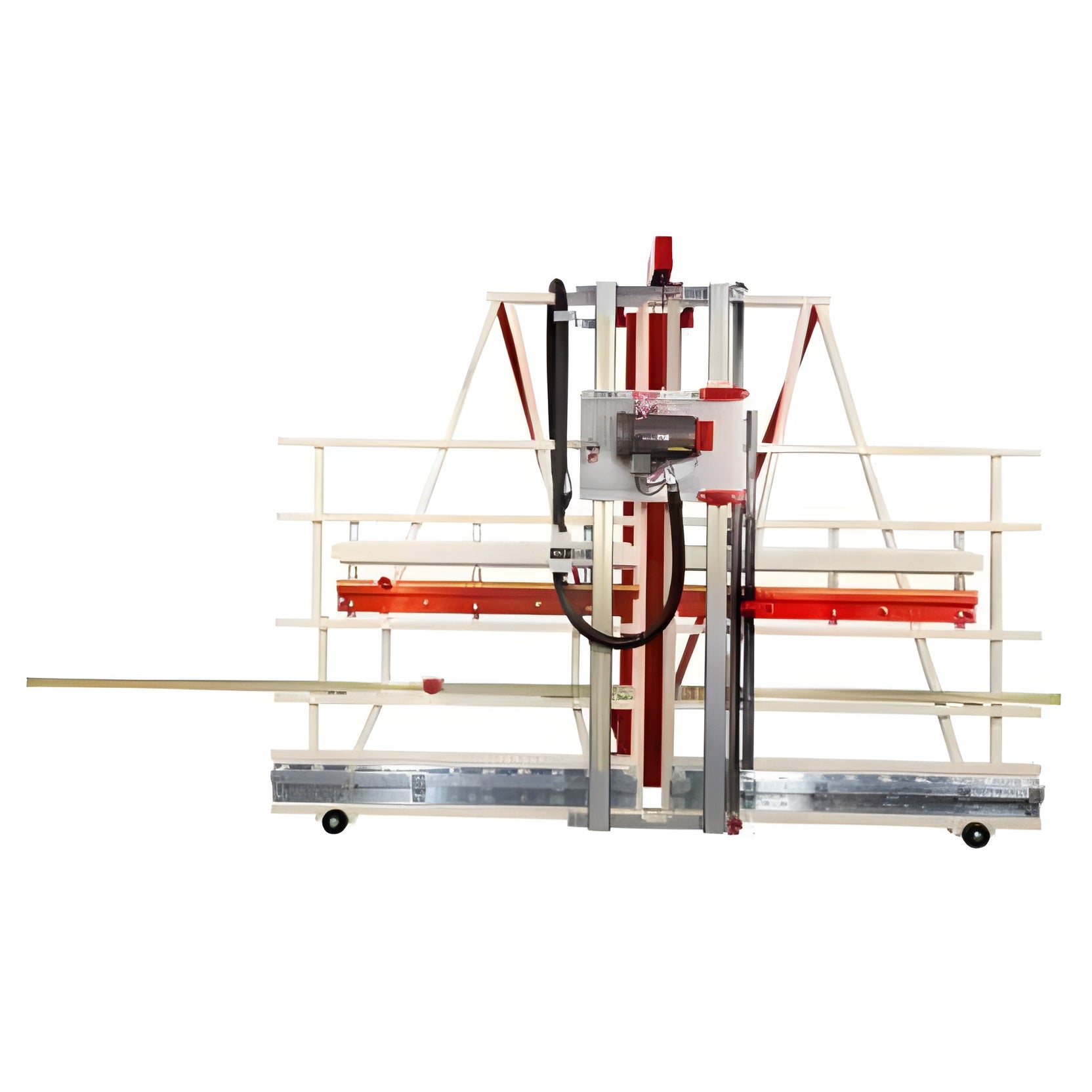

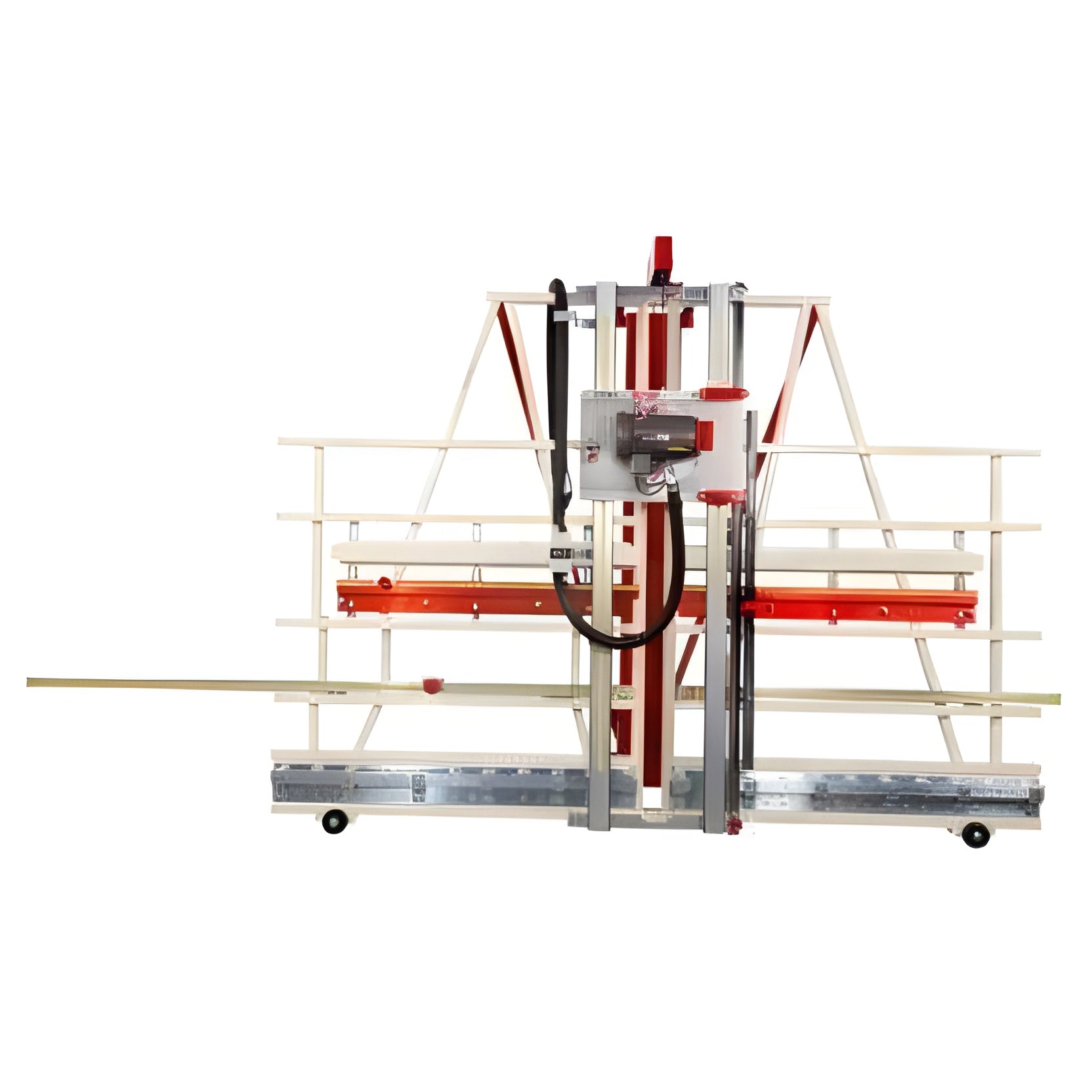

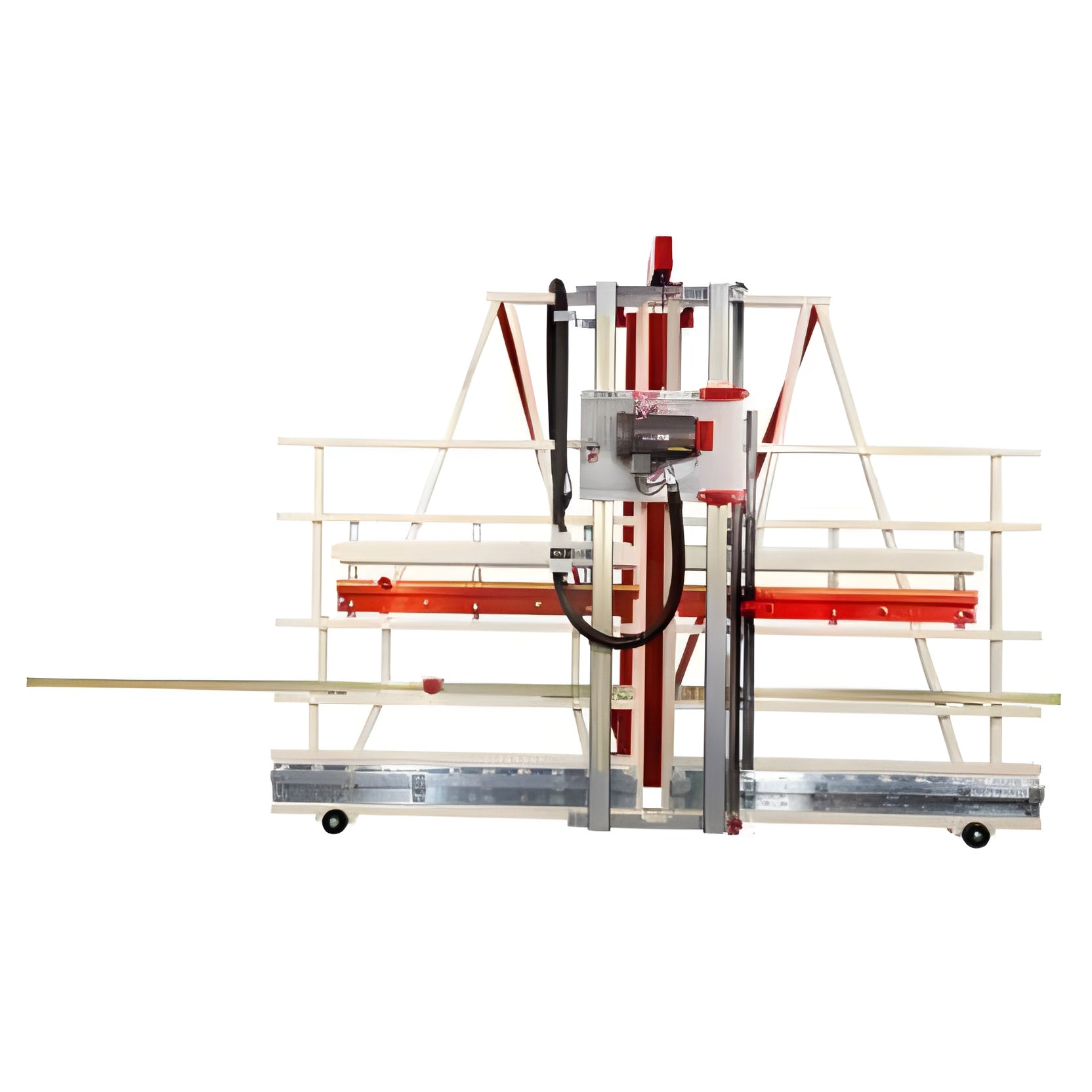

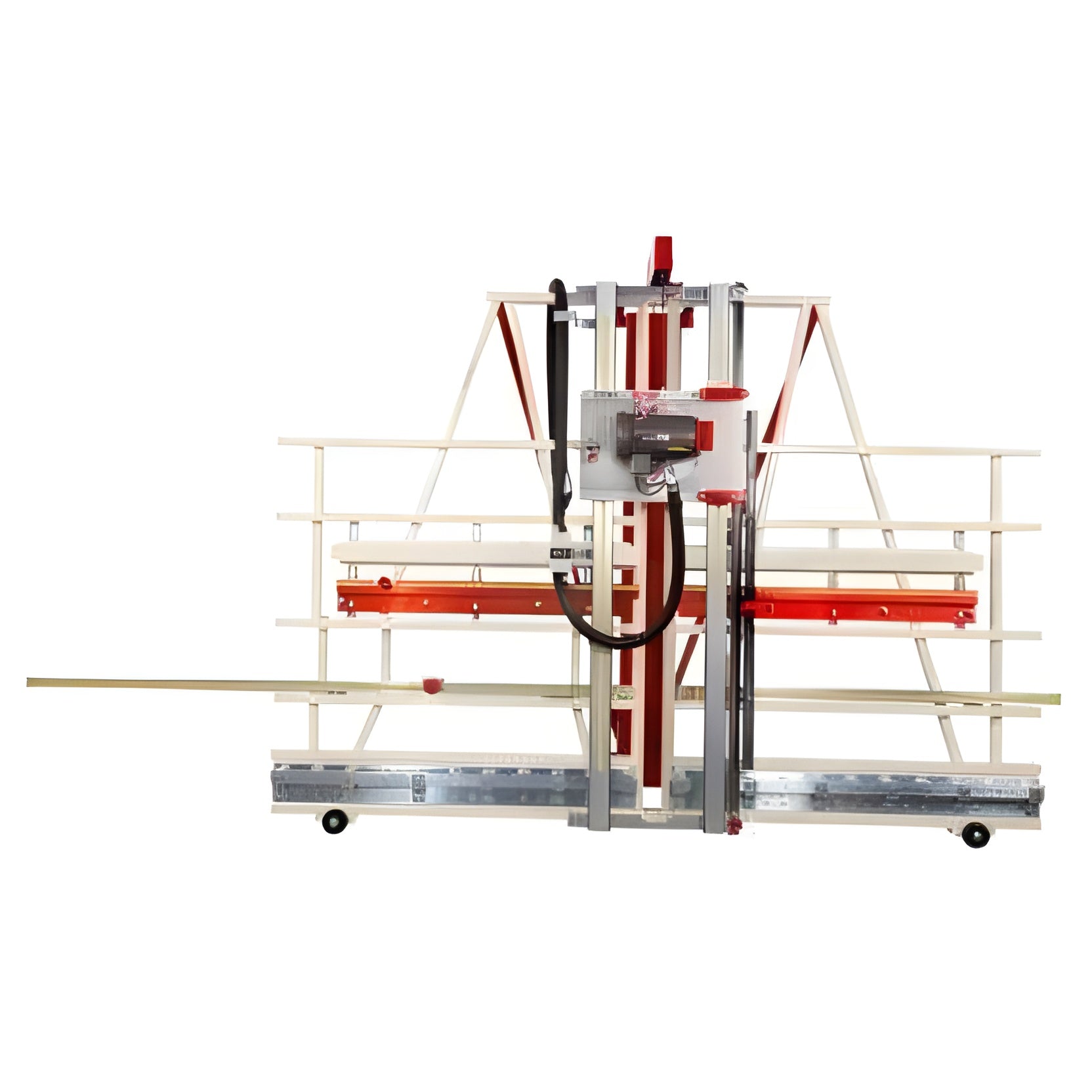

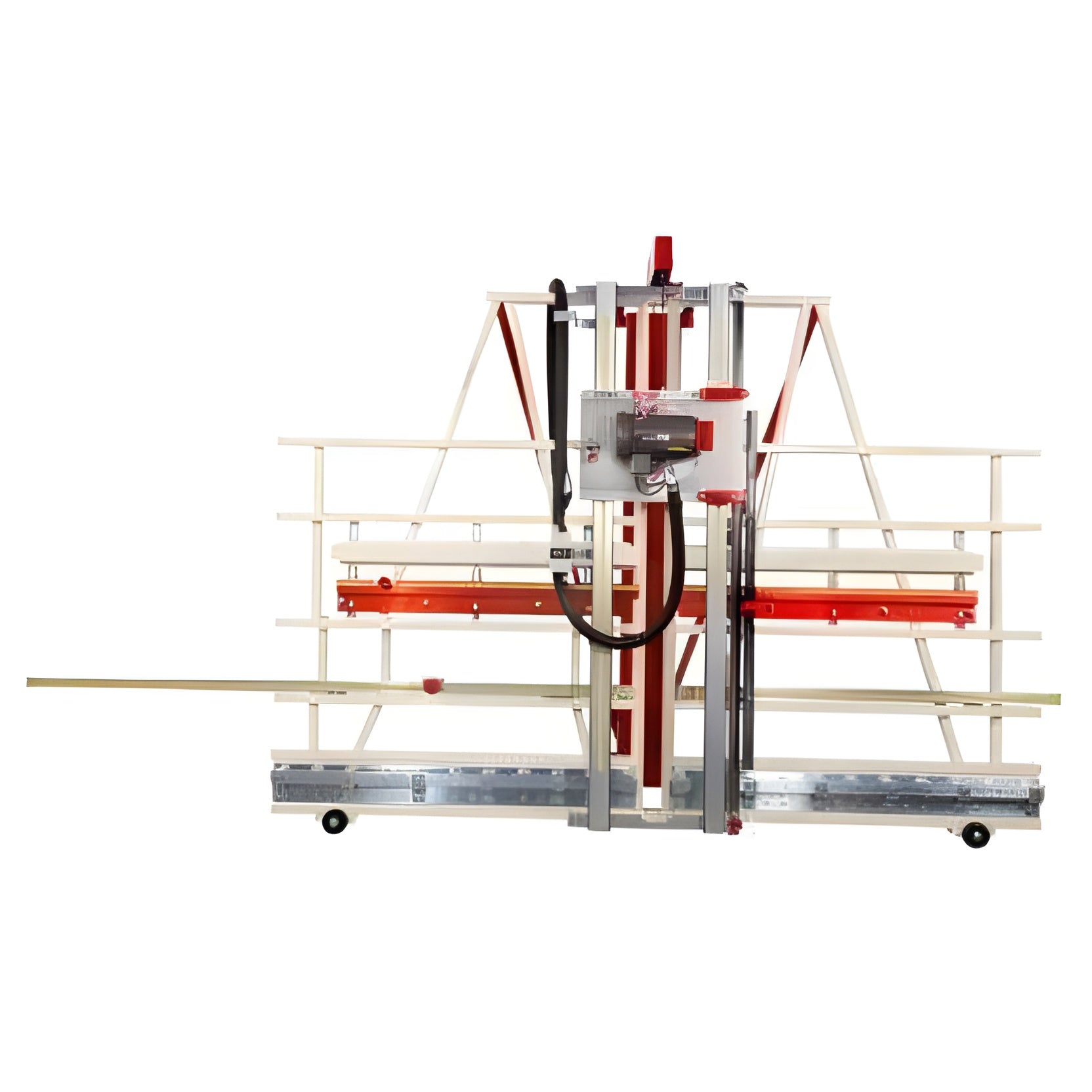

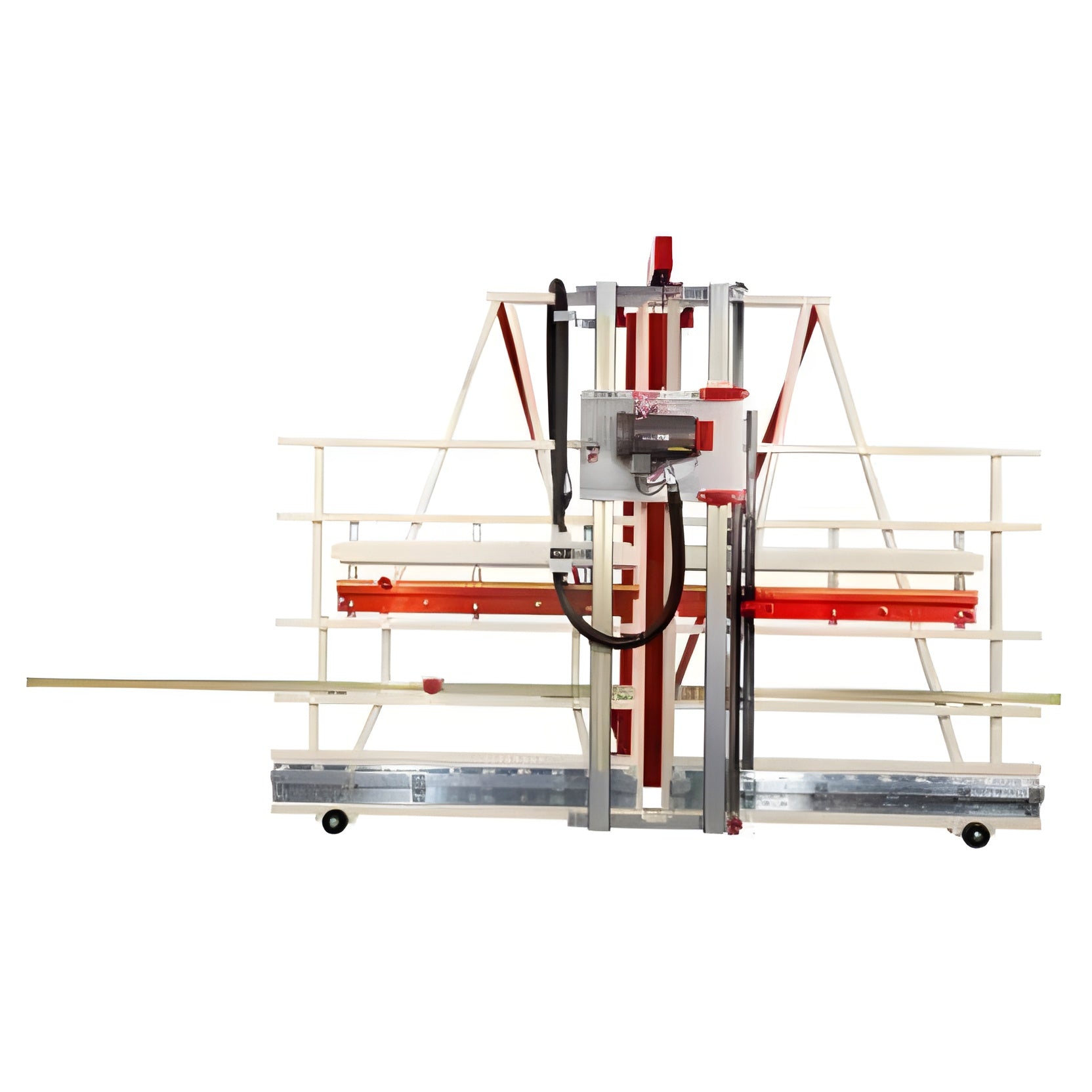

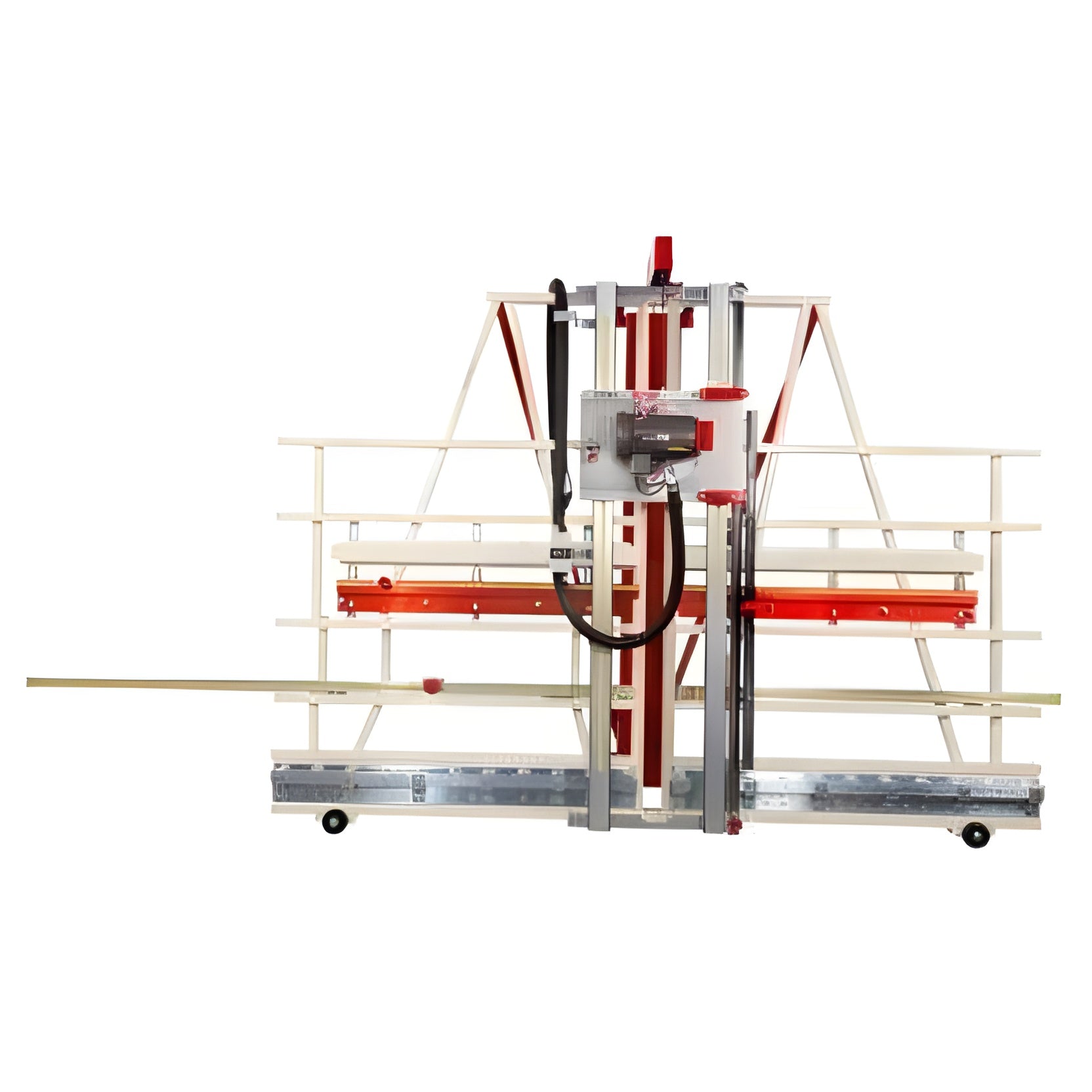

Safety Speed 7400 Panel Saw

- $12,699.00

$13,468.00- $12,699.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Safety Speed 7400 Panel Saw

Continuous usage panel processing done the easy way. The 7400M panel saw features a 10′ frame, and the 7400XL features a 13′ frame. There are no other differences between these two machines.

Built with many similarities as the 7000 model including high induction motors, key upgrades on the 7400 & 7400XL include:

- Rigid beams and rugged frame improving cut accuracy

- Our patented MID-WAY® Fence built into the machine

- 22 aluminum material rollers on the 7400

- Tighter cutting tolerance of .005″

- 2.125” depth of cut

Material scoring is optional yet recommended for those processing premium wood, or melamine.

Accessories built onto this machine and incorporated in the price include:

- Quick stop gauges (8′ left, 5′ right)

- Wheels

- MID-WAY FENCE® for processing panels at waist level

- Dust kit

- 864NRATB saw blade

- Hold Down Bar

- and a stand integrated within the machine

Features

- Your choice of single or three phase, heavy duty induction saw motor.

- Welded steel frame and integrated stand system.

- Dual V-track precision guide system.

- Adjustable vertical and horizontal rulers

- Quick stop gauges (8′ left, 5′ right).

- Saw blade. Quick change from vertical to horizontal cutting.

- Floating pressure saw foot.

- Solid aluminum material rollers.

- Enclosed counterweight system.

- MID-WAY FENCE™.

- Dust collection ready.

- Hold down bar.

- Wheels.

- 3 year warranty.

- TUV certified to UL/CSA standards

Specifications

| Weight | 950 lbs |

|---|---|

| Dimensions | 124 × 98 × 48 in |

| Max. Crosscut |

64'/1625mm |

| Max. Rip Cut |

Unlimited |

| Cut Depth |

2 ⅛'/55mm |

| Cut Accuracy |

.005'/.125mm |

| Frame Length |

120'/3050mm |

| Daily Usage |

Continuous (8+ Hours) |

| Rollers |

22 |

| Saw Blade Diameter |

8'/210mm |

| Motor |

2HP, 1~ 230V, 3HP, 3~ 230V, 3HP, 3~ 460V |

Documents

Product manual

Product parts

7400 Panel Saw Sheet

What Our Experts Think

- Precision Cutting: The Safety Speed 7400 Panel Saw is designed for clean, accurate cuts on large panels, ensuring smooth and professional results in woodworking projects.

- Heavy-Duty Build: Constructed from industrial-grade materials, this saw is built to withstand high-volume, continuous use, making it ideal for demanding shop environments.

- User-Friendly Operation: The simple control system makes the machine easy to operate, minimizing setup time and improving overall shop efficiency.

- Versatile Performance: Capable of cutting various materials like plywood, MDF, and composites, offering flexibility for different woodworking applications.

- Space-Efficient: The compact design is perfect for workshops with limited floor space while providing ample cutting capacity.

- Safety Features: Equipped with protective guards and safety mechanisms to ensure operator protection during use.

Q&A

Q: What is the Safety Speed 7400 Panel Saw?

A: The 7400 is a high-performance, industrial-grade panel saw designed to deliver precise cuts on large panels, ideal for woodworking, cabinetry, and high-volume production environments.

Q: What are the key features of the 7400 Panel Saw?

A: The 7400 features a durable, heavy-duty frame, a precision sliding table, a powerful motor, and adjustable cutting depth, providing efficient and accurate cuts on various materials.

Q: What materials can the 7400 Panel Saw cut?

A: This panel saw is capable of cutting wood, plywood, MDF, particleboard, and laminates, making it ideal for a wide range of woodworking and cabinetry projects.

Q: How does the sliding table improve cutting accuracy?

A: The sliding table allows for precise movement and easy handling of large panels, providing stability and reducing the risk of errors during cutting.

Q: Is the 7400 suitable for high-volume production?

A: Yes, the 7400 is designed for high-volume, heavy-duty use, making it ideal for professional shops with continuous cutting demands.

Q: What safety features are included with the 7400?

A: The saw includes protective guards, emergency stop buttons, and safety switches to ensure safe operation for the user.

Q: Is the 7400 Panel Saw easy to maintain?

A: Yes, it is designed with ease of maintenance in mind, offering accessible components for cleaning, lubrication, and regular servicing to ensure consistent performance.

Maintenance Tips

-

Clean After Each Use: Regularly clean the saw blade, work area, and rails to remove sawdust and debris. Use a soft cloth, air compressor, or vacuum system to keep the components clean and prevent buildup that may affect performance.

-

Inspect and Replace Saw Blade: Check the saw blade for signs of wear or dullness. Replace or sharpen the blade when necessary to ensure accurate cuts and reduce the strain on the motor.

-

Lubricate Moving Parts: Lubricate the rails, guides, and carriage system periodically to ensure smooth movement. Use the manufacturer-recommended lubricant to minimize friction and wear.

-

Tighten and Check Fasteners: Inspect and tighten all screws, bolts, and fasteners to prevent vibration or misalignment during operation. Ensure that the saw is properly aligned to maintain precise cutting.

-

Examine and Adjust the Carriage: Check the carriage system for smooth operation. Make sure it moves freely along the rails and adjust if necessary to ensure proper alignment and cutting accuracy.

-

Dust Collection System Maintenance: Regularly inspect the dust collection system for any blockages or inefficiencies. Clean the hoses, filters, and connections to ensure effective dust removal.

-

Check Electrical Components: Inspect the wiring, switches, and electrical connections for any signs of damage or wear. Ensure that all components are functioning properly and are securely connected.

-

Safety Features Inspection: Regularly check all safety features, such as blade guards, emergency stops, and safety switches, to ensure they are functioning correctly and free from obstructions.

Related Products

- Choosing a selection results in a full page refresh.