Get In Touch +1 (888) 575-2099

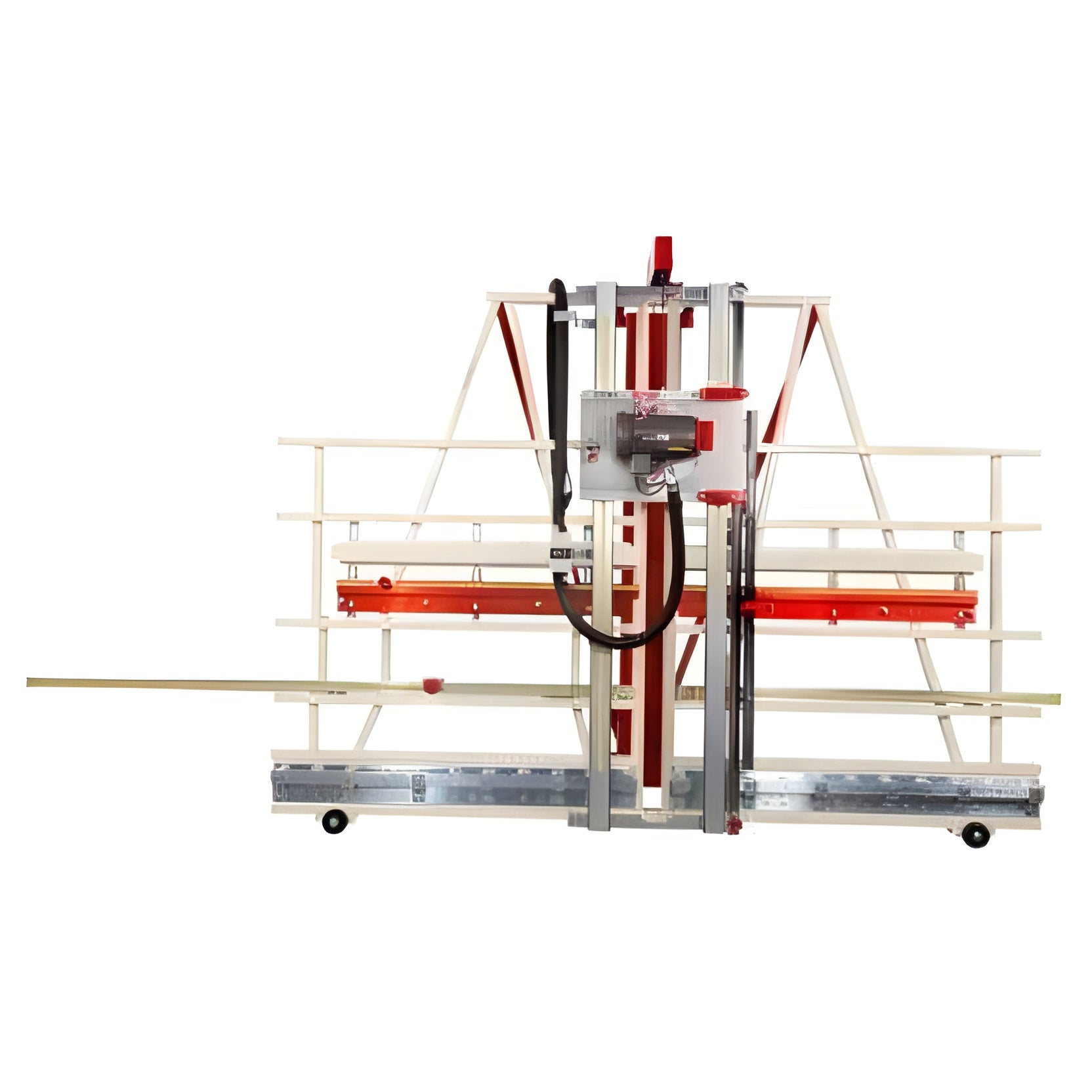

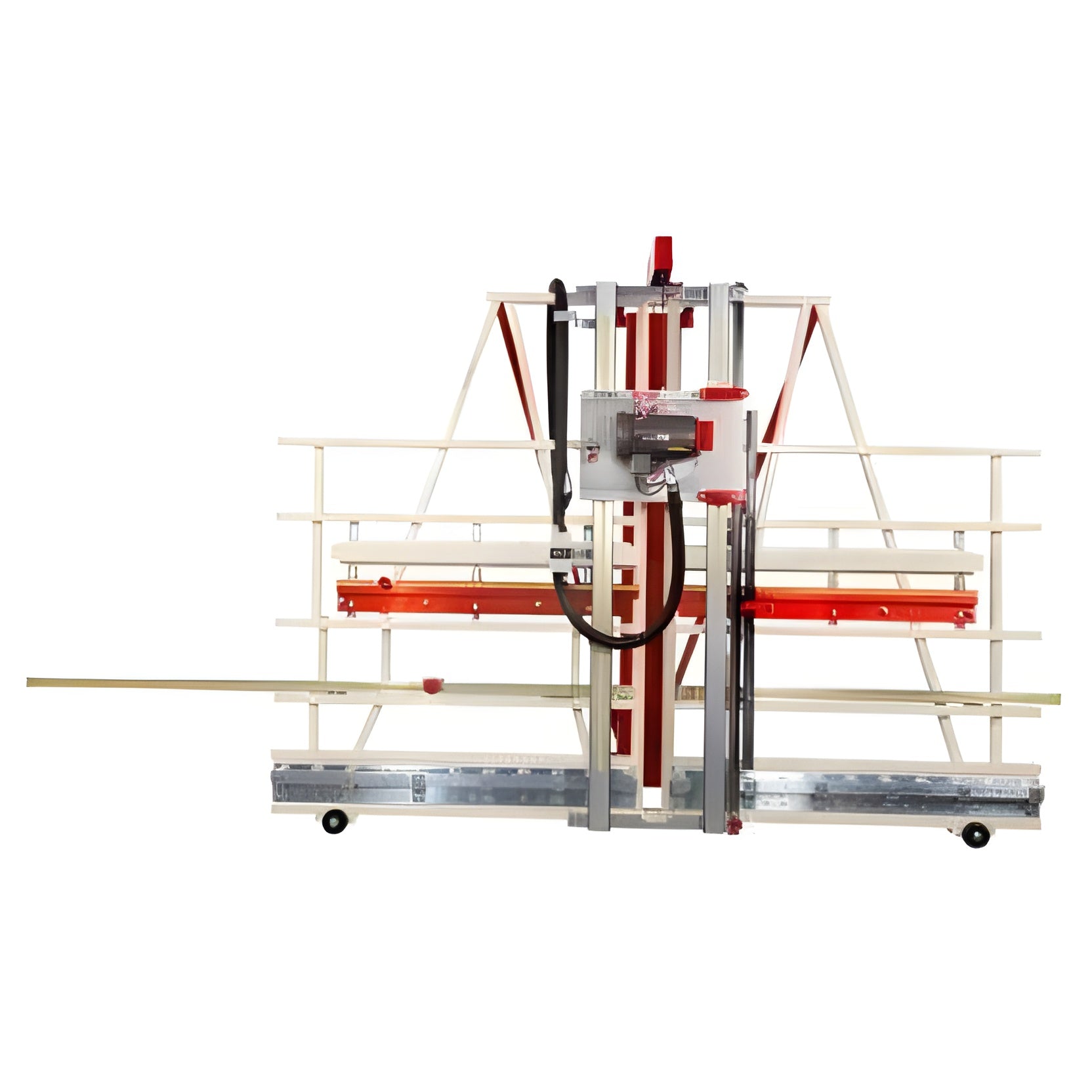

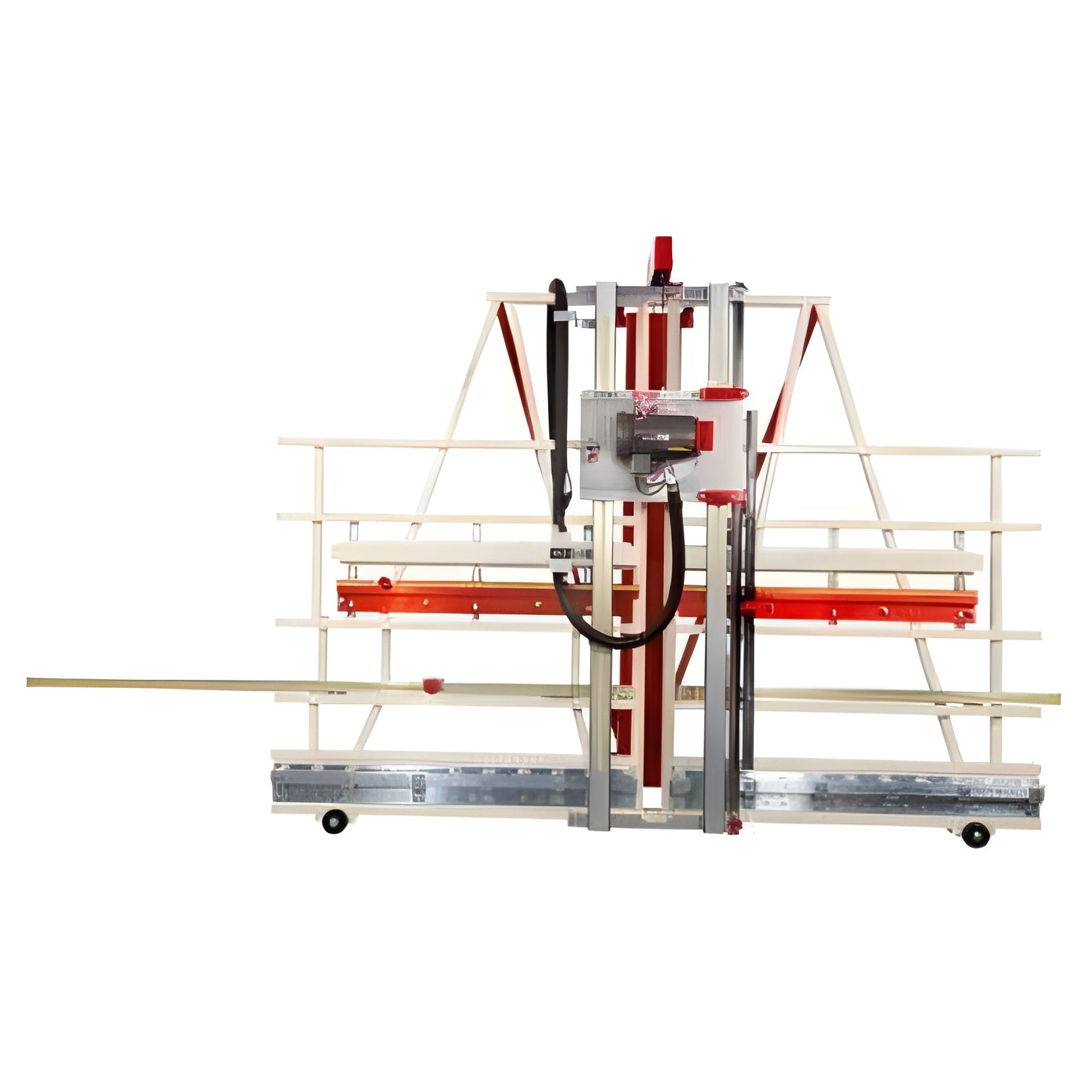

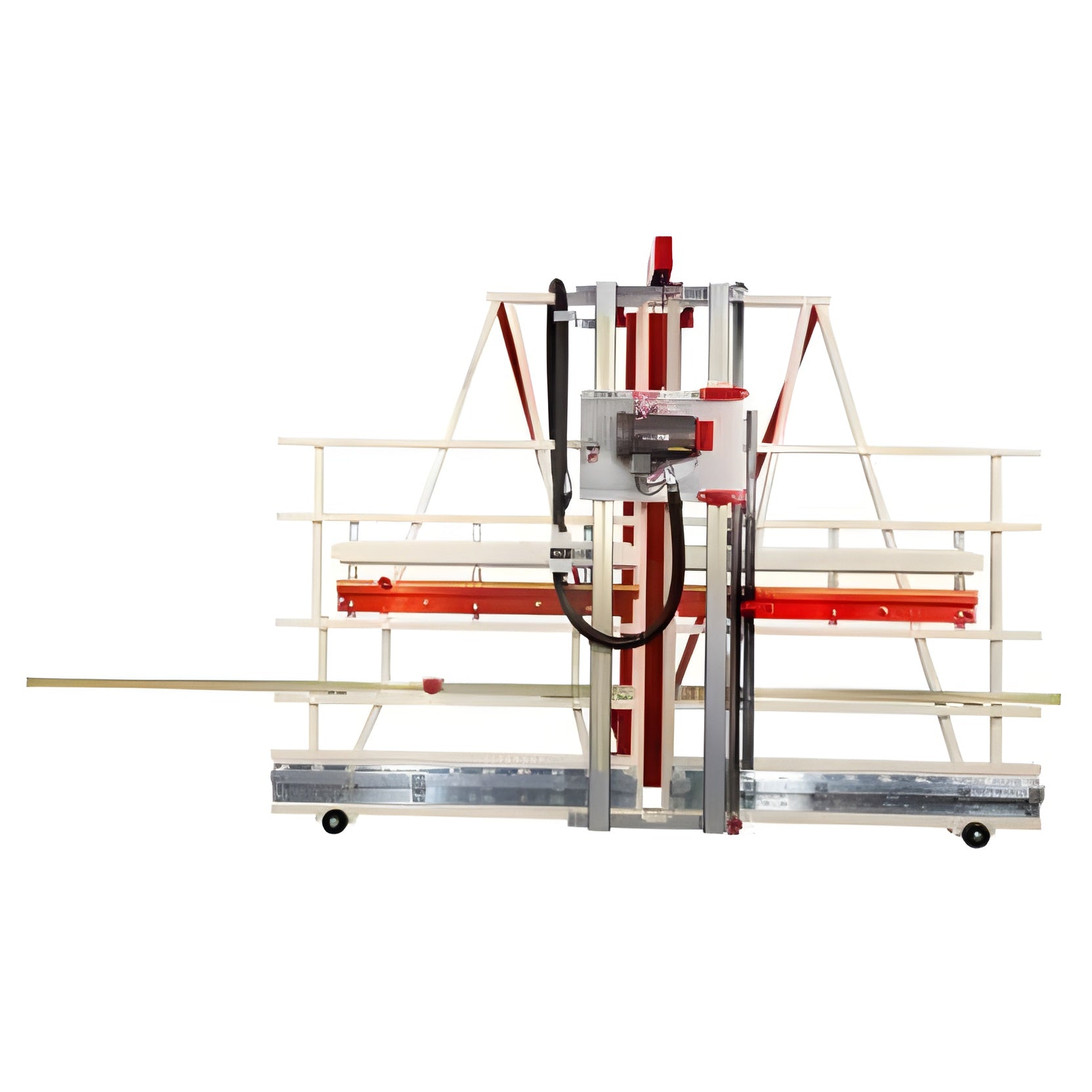

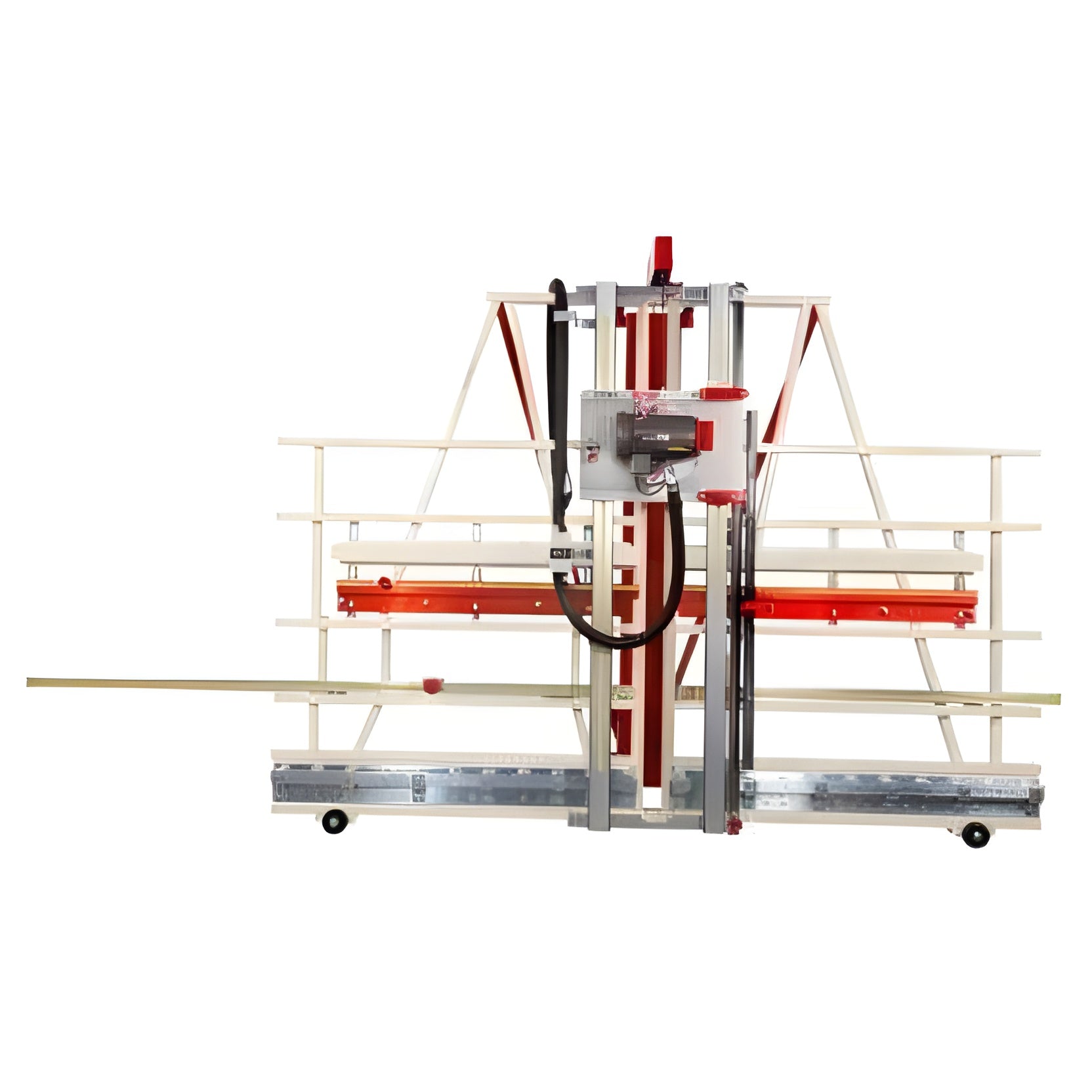

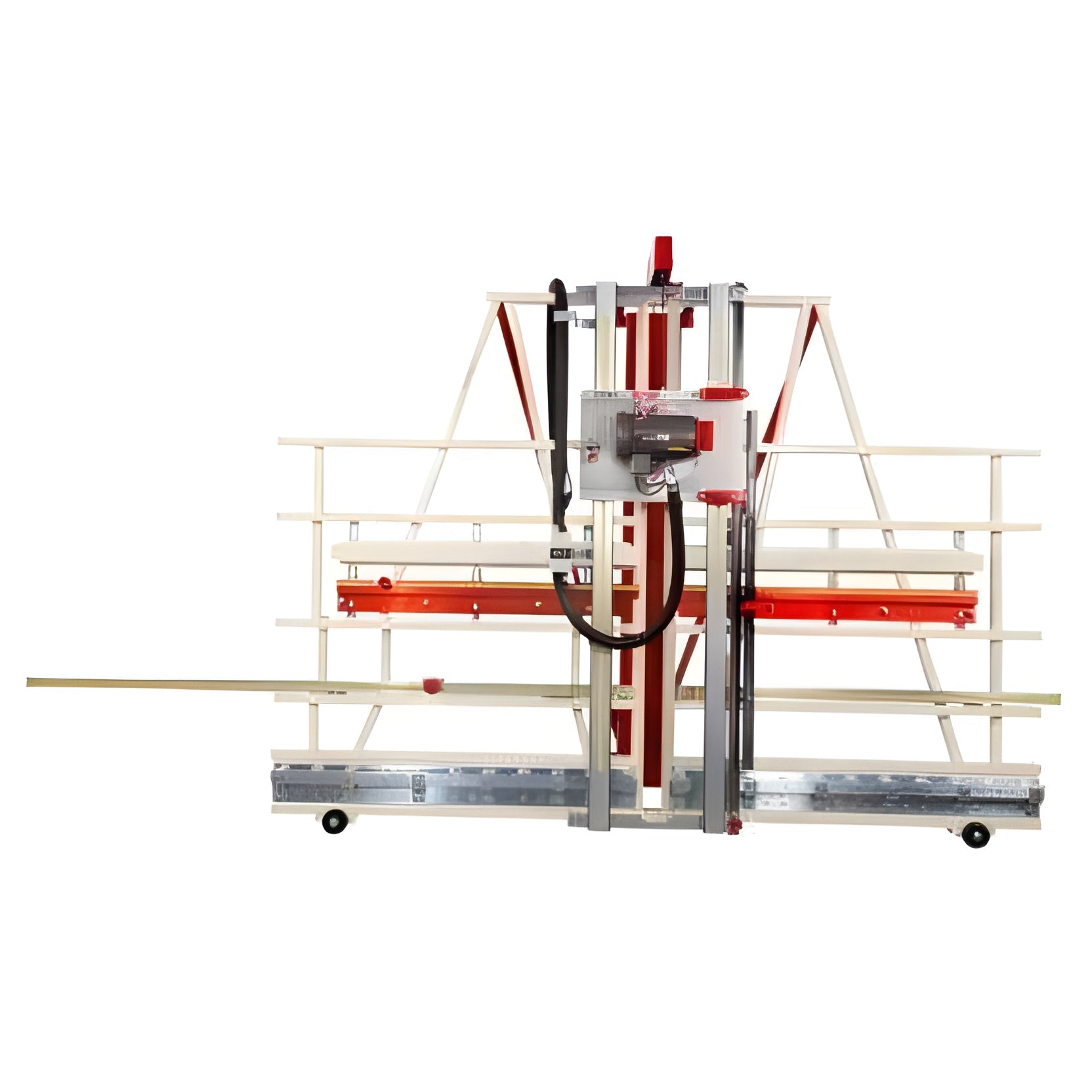

Safety Speed 7400XL Panel Saw

- $14,999.00

$15,468.00- $14,999.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Safety Speed 7400XL Panel Saw

High production panel processing is now a reality. Cut material 2 1/8″ deep for 8+ hours per day and within .005″ straight and square. Every component of this saw represents quality and performance. Featuring three different motor configurations, heavy extruded beams with precise dual-vee bearings, and the sturdiest frame on the market, these top of the line woodworking tools will boost your shops production. The 13′ frame is only difference between this machine and the 7400-M panel saw.

The only major difference between this machine and the 7400 Panel Saw is that the 7400XL features a 13′ frame

Accessories built onto this machine and incorporated in the price include:

- Quick stop gauges (8′ left, 5′ right)

- Wheels

- MID-WAY FENCE® for processing panels at waist level

- Dust kit

- 864NRATB saw blade

- Hold Down Bar

- and Stand integrated within the machine

Features

- Continuous usage induction saw motor.

- Welded steel frame and integrated stand system.

- Dual V-track precision guide system.

- Adjustable vertical and horizontal rulers.

- Floating pressure saw foot.

- Solid aluminum material rollers.

- Enclosed counterweight system.

- Dust collection ready.

- 3 year warranty.

- TUV certified to UL/CSA standards

Specifications

| Weight | 1050 lbs |

|---|---|

| Dimensions | 160 × 98 × 48 in |

| Max. Crosscut |

64'/1625mm |

| Max. Rip Cut |

Unlimited |

| Cut Depth |

2 ⅛'/55mm |

| Cut Accuracy |

.005'/.125mm |

| Frame Length |

156'/3950mm |

| Daily Usage |

Continuous (8+ Hours) |

| Rollers |

28 |

| Saw Blade Diameter |

8'/210mm |

| Motor |

2HP, 1~ 230V, 3HP, 3~ 230V, 3HP, 3~ 460V |

Documents

Product manual

Product parts

7400XL Panel Saw Sheet

What Our Experts Think

- High-Precision Cutting: The Safety Speed 7400XL Panel Saw delivers smooth, accurate cuts, making it ideal for high-volume panel cutting in woodworking and cabinetry.

- Heavy-Duty Performance: Designed with industrial-grade materials, this saw is built to handle continuous, heavy-duty use in professional workshops, ensuring long-lasting durability.

- User-Friendly Features: Equipped with intuitive controls, it’s easy to set up and operate, reducing operator training time and enhancing workflow efficiency.

- Versatile: The 7400XL is suitable for cutting a variety of materials, including plywood, MDF, and composites, making it a versatile tool for woodworking professionals.

- Space-Efficient Design: Its compact design maximizes shop space while still providing large cutting capacity, perfect for shops with limited floor area.

- Safety Features: Built with safety in mind, the machine includes protective guards and features to ensure operator safety during operation.

Q&A

Q: What is the Safety Speed 7400XL Panel Saw?

A: The 7400XL is a heavy-duty, industrial panel saw designed for precise cutting of large panels, ideal for woodworking, cabinetry, and other high-volume applications.

Q: What are the key features of the 7400XL Panel Saw?

A: The 7400XL features a powerful motor, large cutting capacity, an adjustable sliding table, and a sturdy frame, ensuring smooth, accurate cuts on a variety of materials.

Q: What materials can the 7400XL Panel Saw cut?

A: The saw can cut wood, plywood, MDF, particleboard, and laminate, making it ideal for cabinetry, furniture, and custom woodworking projects.

Q: How does the sliding table enhance the cutting process?

A: The adjustable sliding table provides easy handling of large panels, improving cutting accuracy and reducing operator effort, especially for long or heavy sheets.

Q: Is the 7400XL suitable for high-volume production?

A: Yes, the 7400XL is built for heavy-duty use, making it perfect for high-volume production in professional woodworking shops and factories.

Q: What safety features are included with the 7400XL?

A: The panel saw includes safety guards, emergency stop switches, and other protective features to ensure safe operation during use.

Q: Is the 7400XL easy to maintain?

A: Yes, the machine is designed for easy maintenance with accessible components for cleaning, lubrication, and regular servicing to maintain optimal performance.

Maintenance Tips

-

Clean After Each Use: Wipe down the saw blade, rails, and the work area to remove sawdust and debris. Use a soft cloth or air compressor to clean the machine thoroughly.

-

Inspect and Replace Saw Blade: Regularly inspect the saw blade for signs of wear, such as dullness or chips. Replace or sharpen the blade as needed to maintain clean cuts.

-

Lubricate Rails and Guides: Lubricate the rails and guide systems regularly to ensure smooth movement and reduce wear on the machine’s components.

-

Check and Tighten Fasteners: Inspect bolts, screws, and fasteners to ensure they are tight and secure. Periodically check the overall alignment and calibrate the saw to maintain cutting precision.

-

Examine the Carriage System: Check the carriage for smooth operation. Lubricate moving parts and ensure the carriage moves freely along the rails.

-

Dust Collection System: Clean and maintain the dust collection system by checking for blockages, replacing filters, and ensuring proper airflow to maintain effective dust removal.

-

Monitor Electrical Components: Check electrical connections and wiring for wear or damage. Ensure proper grounding and replace any damaged components to prevent electrical issues.

-

Check the Saw’s Safety Features: Regularly inspect the safety features, such as blade guards and emergency stops, to ensure they are functional and free from obstruction.

Related Products

- Choosing a selection results in a full page refresh.