Get In Touch +1 (888) 575-2099

Safety Speed SPM301 Screw Pocket Machine

- $5,999.00

$6,985.00- $5,999.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Safety Speed SPM301 Screw Pocket Machine

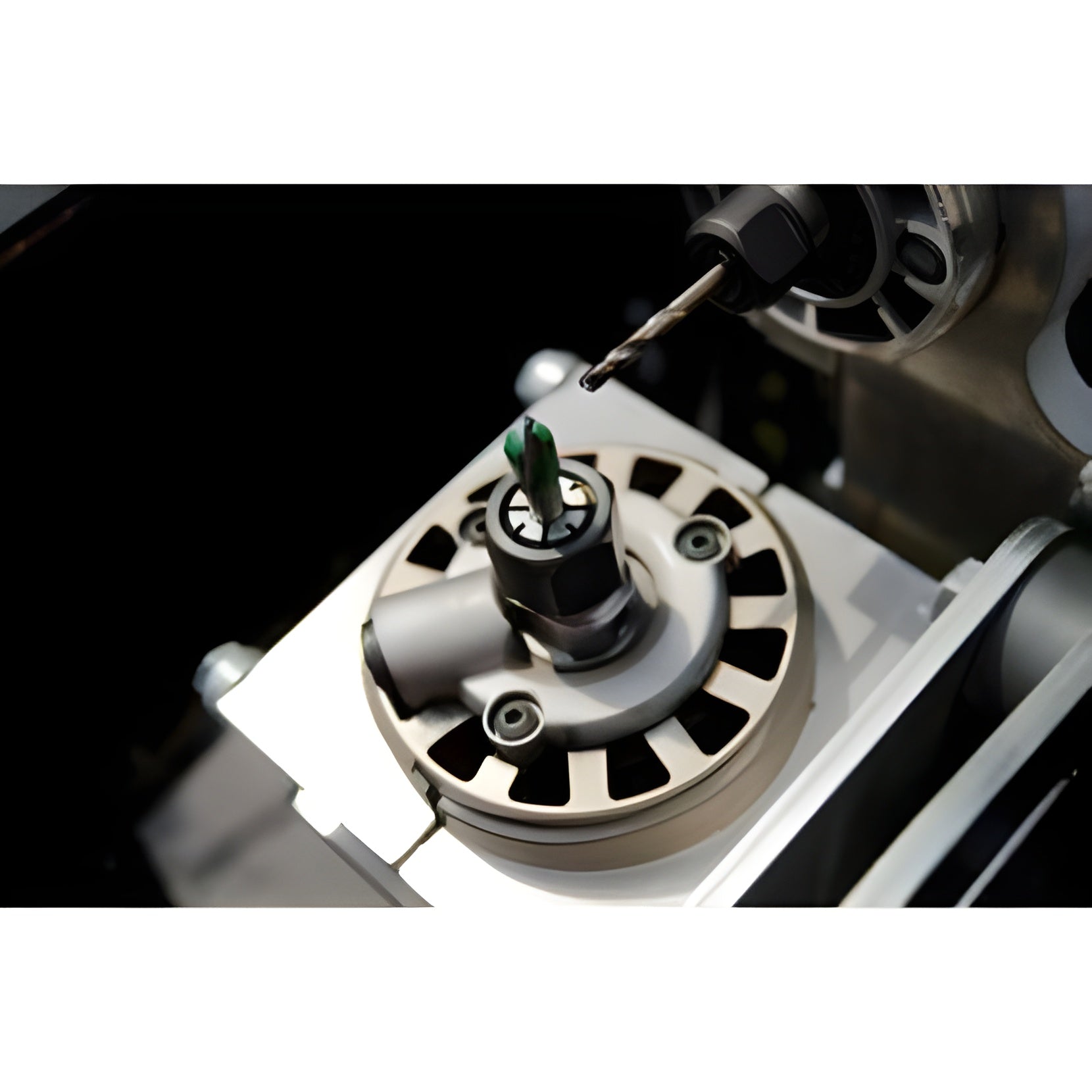

The SPM301’s mechanical linkage allows the pilot drill and router bit to cut at the same time, reducing cycle time without sacrificing cut quality. Simple back fence, stop rail, and depth adjustment make setups and adjustments quick and easy. The built-in analog depth gauge allows changing material thickness a breeze and can be completed within seconds. When it comes to manufacturing, the SPM301 is unmatched. Manufactured completely in the USA, the SPM301 showcases heavy duty construction; a machine truly built to be a work horse and requires only standard 110 VAC and 1-2 CFM compressed air at 80 PSI.

Unlike others of its kind, the SPM301 features cam-driven action providing fast, smooth cutting action under complete mechanical control throughout the machine cycle. The pilot drill and ball end mill produce superior low-angle screw pockets.

Product demonstration

Specifications

| Weight | 350 lbs |

|---|---|

| Dimensions | 27 × 34 × 49 in |

| Router Motor |

2 1/4 Hp |

| Drill (Compact Router) |

7 amp/16,000-27,000 RPM |

| Vacuum Requirement |

220 CFM, 3' Hose Connection |

| Air Requirement |

1-2 CFM at 80 PSI |

| Dimensions (Shop) |

22'W x 44'H x 26'D |

Documents

Product manual

Product parts

Features on Safety Speed Screw Pocket Machines

SPM301 & SPM301HD Catalog Page

SPM301 Sales Sheet

What Our Experts Think

- Efficient Screw Pocket Creation: The Safety Speed SPM301 Screw Pocket Machine is designed to quickly and precisely create screw pockets, improving the efficiency of joinery for cabinetry and furniture manufacturing.

- Heavy-Duty Performance: Built with robust, industrial-grade materials, this machine is made to withstand high-volume use, ensuring longevity and reliability in demanding environments.

- User-Friendly Operation: Simple controls make it easy for operators to adjust settings, reducing setup time and increasing overall productivity.

- Precision Engineering: Ensures accurate pocket drilling with clean, consistent results, enhancing the strength and durability of the joints.

- Space-Saving Design: Compact yet powerful, the SPM301 optimizes shop space while providing the necessary performance for large-scale production.

- Versatile: Ideal for creating screw pockets in a variety of materials, including wood and MDF, making it adaptable for various woodworking projects.

Q&A

Q: What is the Safety Speed SPM301 Screw Pocket Machine?

A: The SPM301 is a high-efficiency screw pocket machine designed for drilling screw pockets in wood panels, making it ideal for joinery and cabinetry production where precise, strong connections are needed.

Q: What are the key features of the SPM301 Screw Pocket Machine?

A: The SPM301 features an adjustable drilling depth, quick-change tooling, a powerful motor, and precision controls for drilling screw pockets with high accuracy and consistency.

Q: What materials can the SPM301 Screw Pocket Machine work with?

A: The machine is designed for use with wood, MDF, plywood, and other similar materials commonly used in cabinetry and furniture production.

Q: How does the SPM301 improve production efficiency?

A: The machine allows for quick and precise drilling of screw pockets, reducing labor time compared to manual drilling methods and improving overall production speed and consistency.

Q: Is the SPM301 suitable for high-volume production?

A: Yes, the SPM301 is built for heavy-duty use and high-volume production, making it ideal for professional shops and factories.

Q: What safety features are included with the SPM301?

A: The SPM301 includes safety guards, emergency stop buttons, and other protective features to ensure safe operation during use.

Q: Is the SPM301 Screw Pocket Machine easy to maintain?

A: Yes, the SPM301 is designed for easy maintenance with accessible components for cleaning and servicing to ensure long-term reliability and performance.

Maintenance Tips

-

Clean After Each Use: Remove sawdust, wood chips, and other debris from the machine after each use. Use a soft cloth or air compressor to clean the machine thoroughly, focusing on the work area and moving parts.

-

Inspect and Maintain Cutter Blades: Regularly inspect the cutter blades for wear, dullness, or damage. Sharpen or replace blades when necessary to ensure clean cuts and prevent excessive wear on the motor.

-

Lubricate Moving Parts: Apply lubricant to the moving components, such as the feed mechanism and the cutting assembly, to reduce friction and ensure smooth operation. Use the manufacturer's recommended lubricant for best results.

-

Check Fasteners and Alignment: Inspect screws, bolts, and fasteners to ensure they are tight and secure. Check the machine's alignment to ensure that all components are properly positioned to maintain accuracy in screw pocket machining.

-

Monitor Feed System: Inspect the feed rollers, conveyors, and other components of the feed system for wear and proper function. Adjust or replace parts if necessary to ensure smooth material feeding and consistent pocket machining.

-

Dust Collection Maintenance: Regularly check the dust collection system for blockages or inefficiencies. Clean the hoses, filters, and connections to ensure effective dust removal and maintain proper airflow.

-

Inspect Electrical Components: Check all electrical wiring, connections, and switches for signs of wear, damage, or loose connections. Ensure proper grounding and replace any damaged electrical components.

-

Check the Motor: Monitor the motor for any unusual noises or overheating. Ensure that it is well-ventilated and running efficiently. Clean the motor housing periodically to ensure adequate airflow.

Related Products

- Choosing a selection results in a full page refresh.