- 3 ¼ Hp, 15 amp router motor.

- Horizontal steel work table.

- Chrome-plated 1 ¾” guide tubes.

- 8 Nylatron roller bearing system.

- Adjustable rulers.

- Integrated dust collection bonnet.

- Floating router head

- 2 clamps.

- 2 blind dado stops.

- Extended warranty.

Get In Touch +1 (888) 575-2099

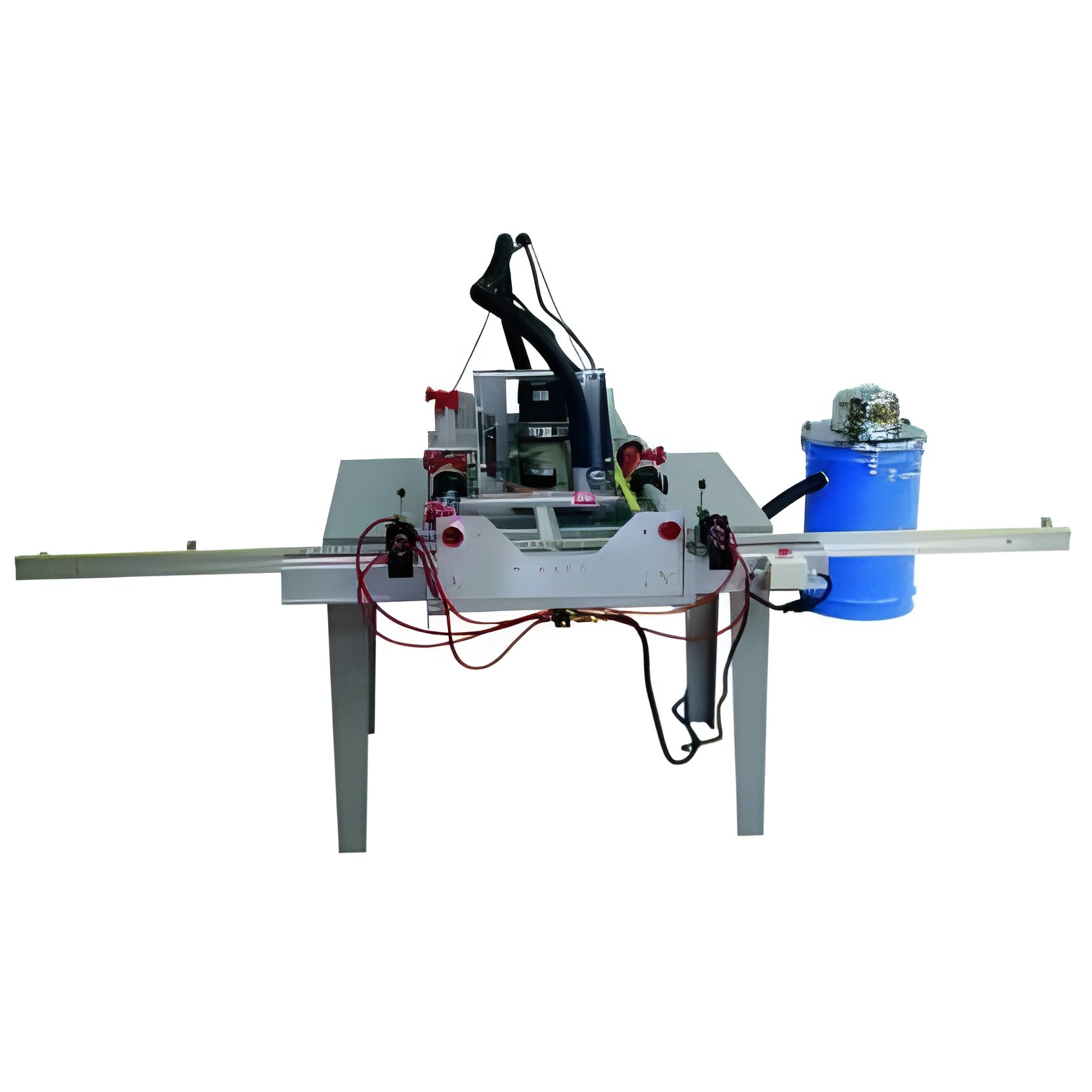

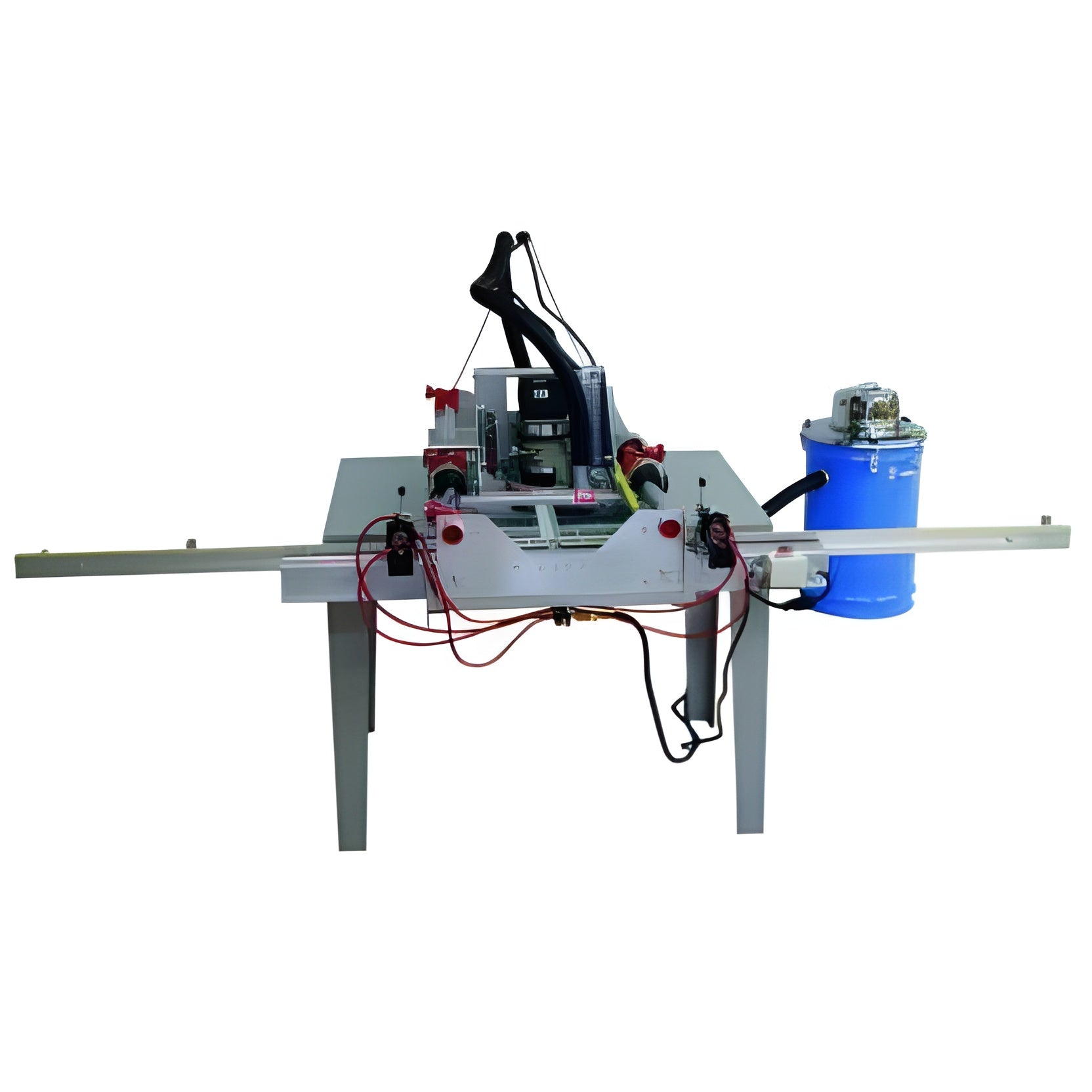

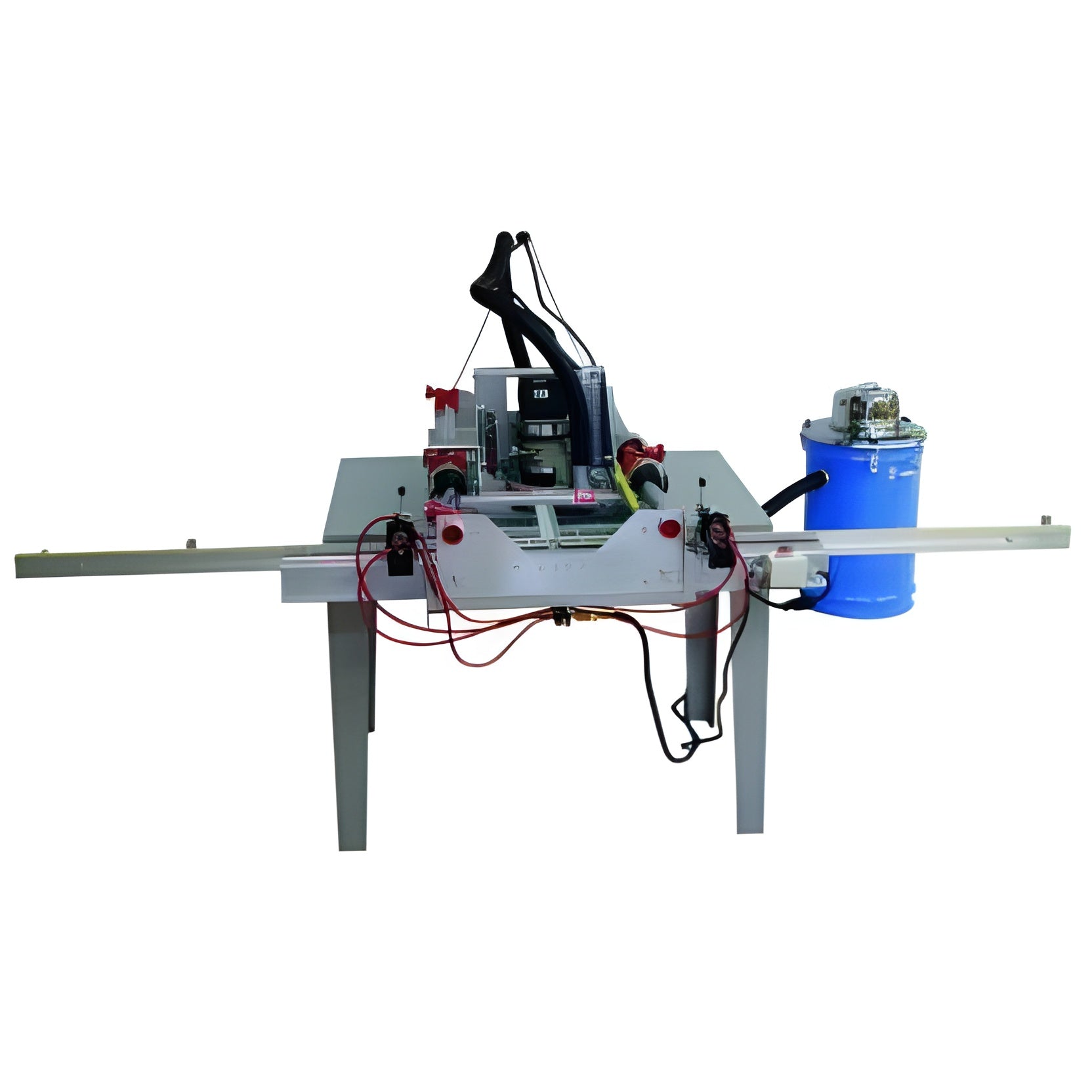

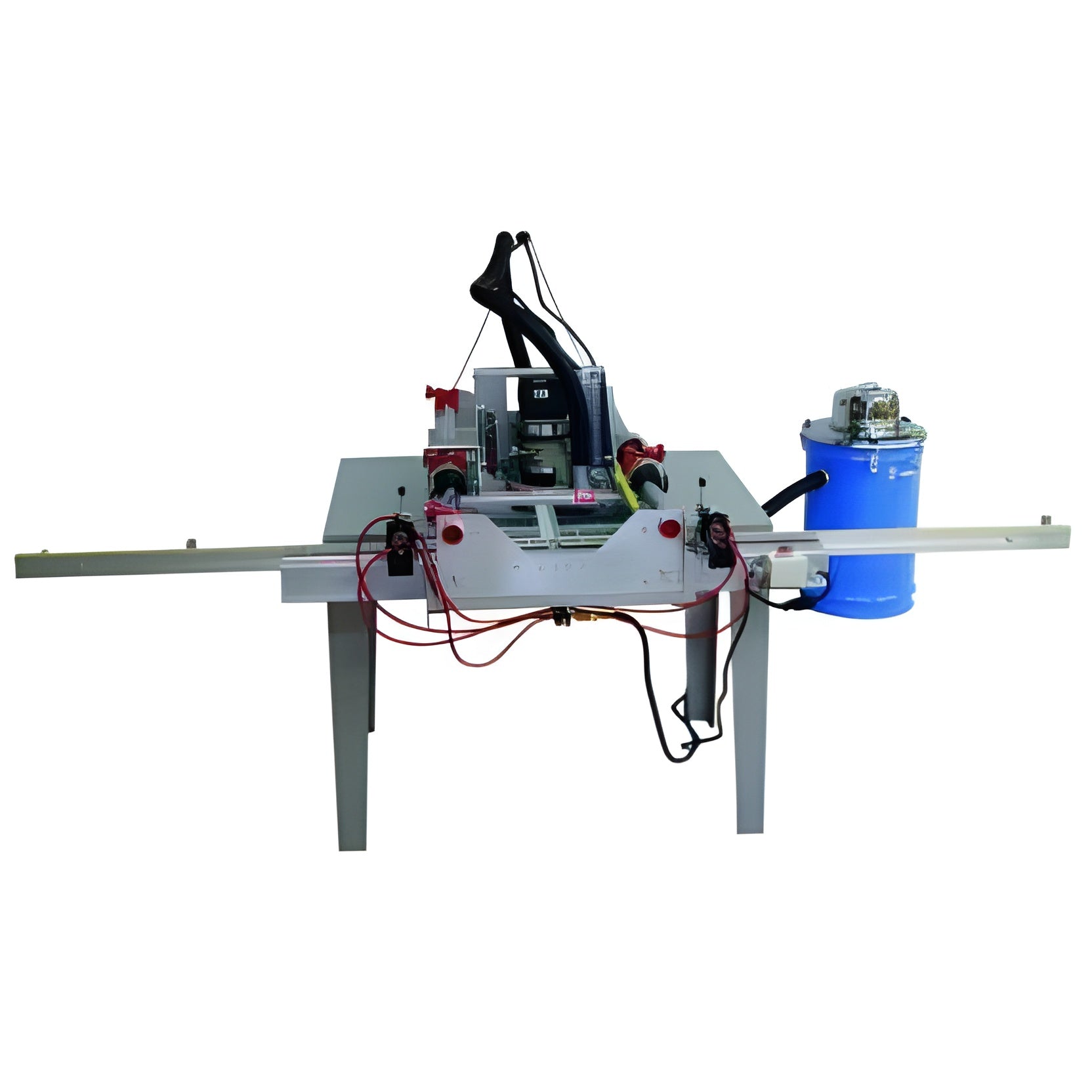

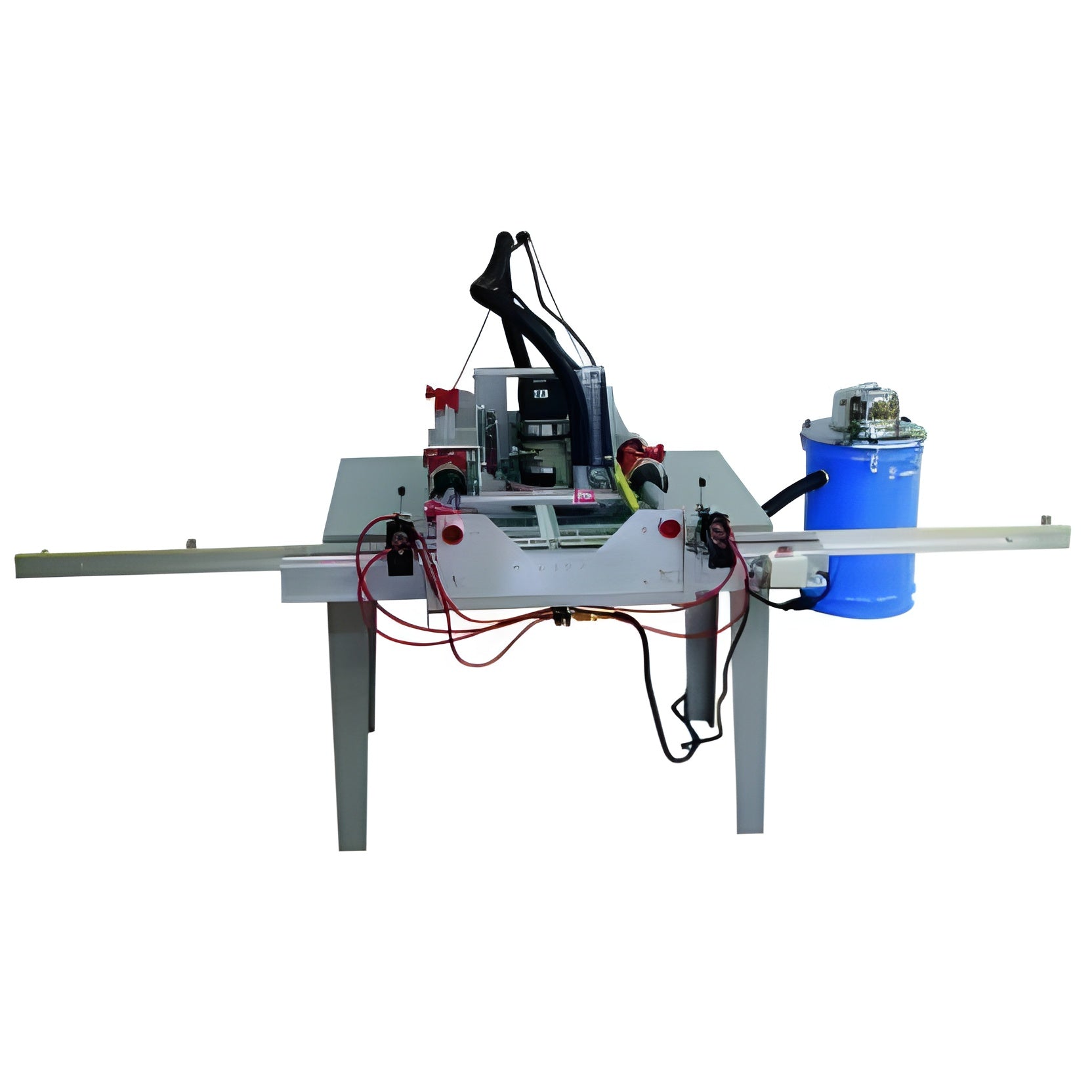

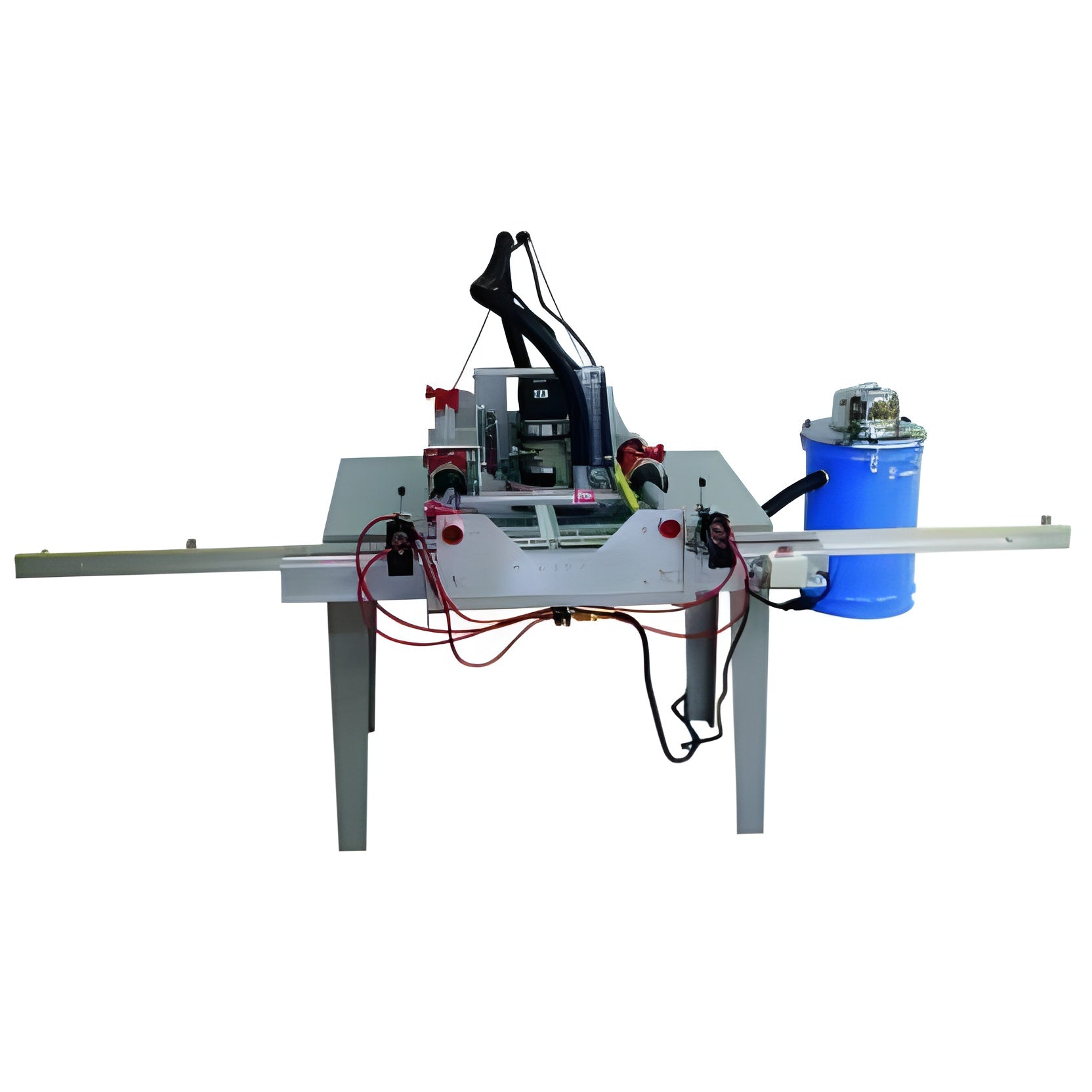

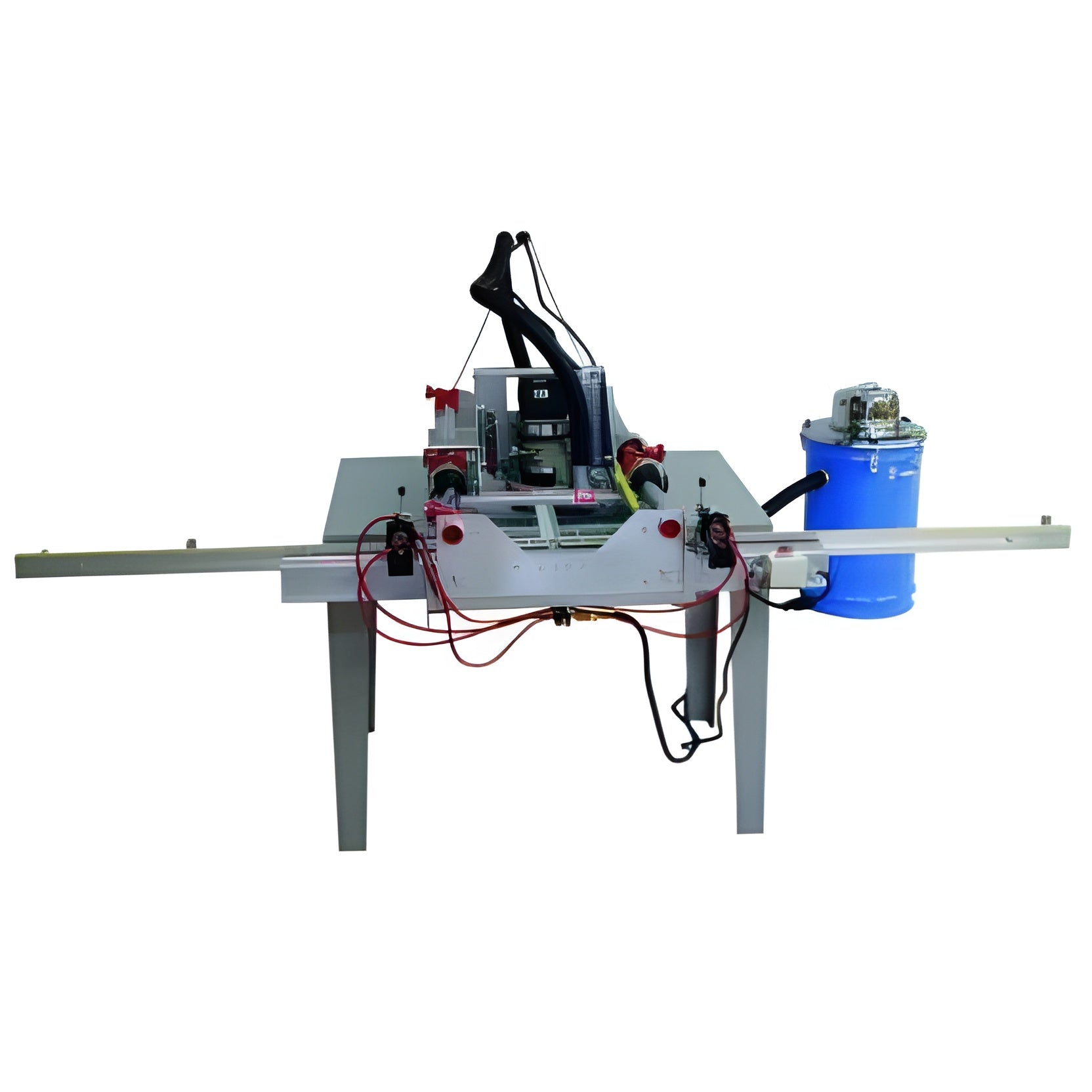

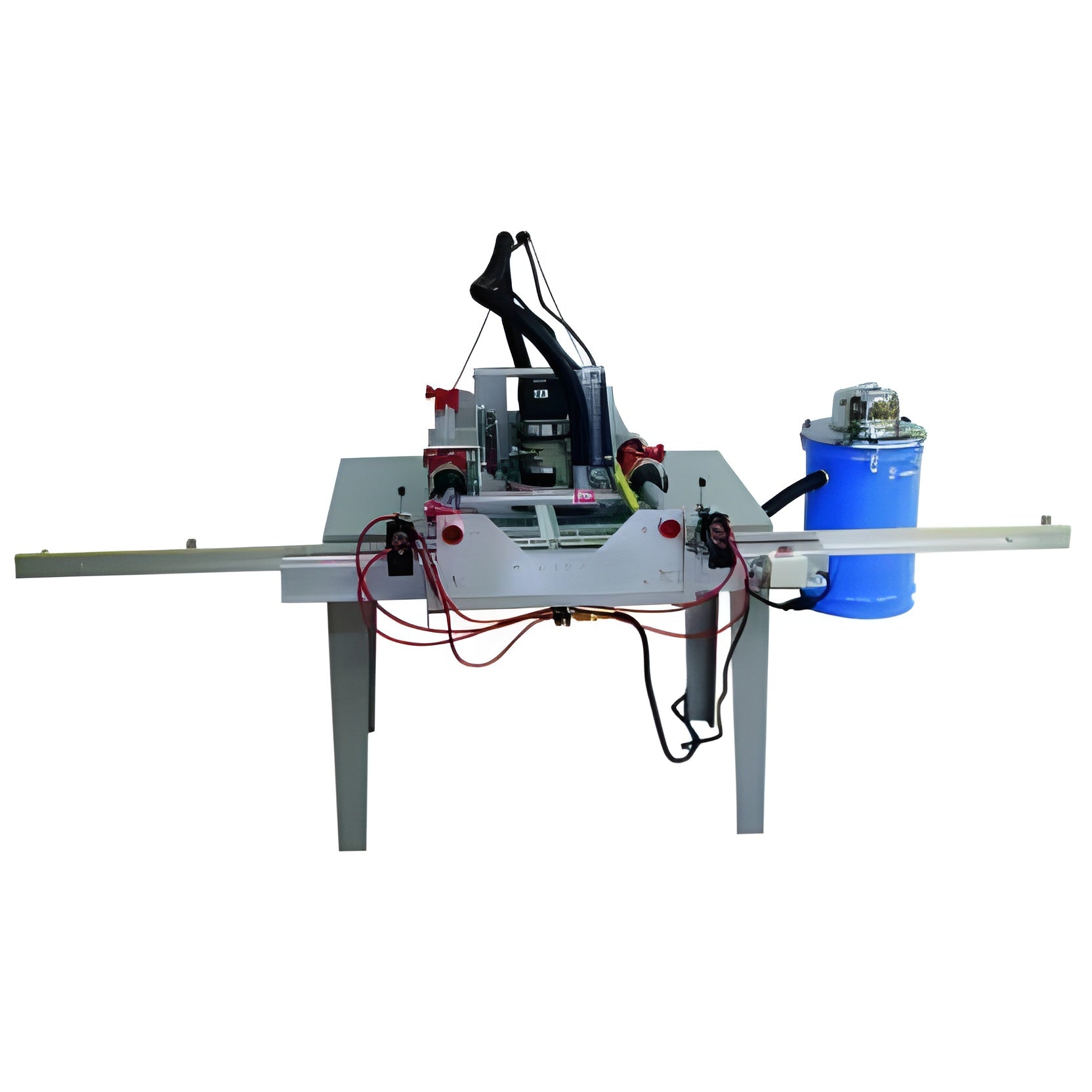

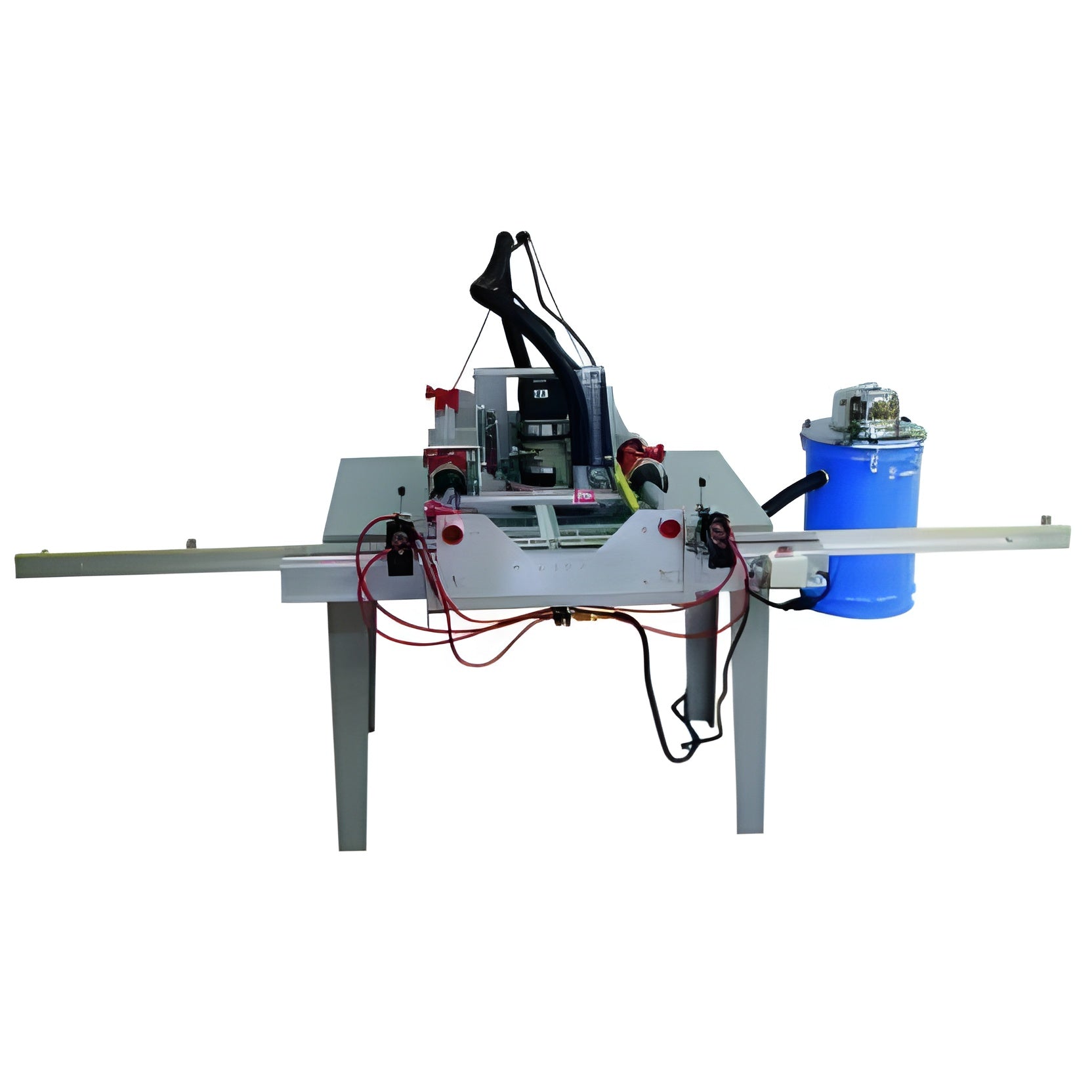

Safety Speed TR2 Table Router

- $5,599.00

$6,768.00- $5,599.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Safety Speed TR2 Table Router

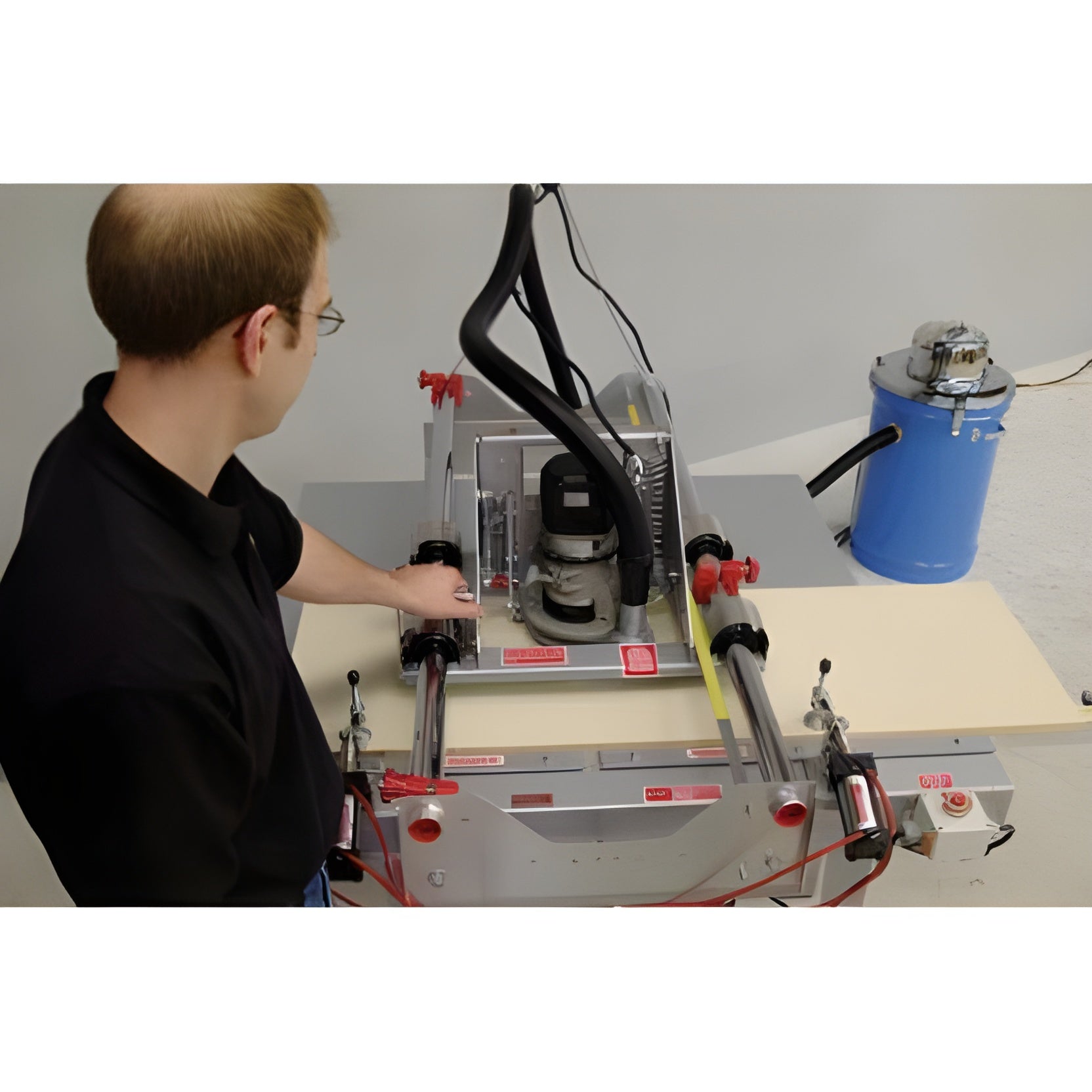

Equipped with a heavy duty 3+ horsepower motor, the TR2 easily cuts standard dados, blind dados as well as full-length rabbets. One person operation makes this machine well suited for wood shops, schools, display manufacturers and cabinet shops. The TR2 panel router is a horizontal model offering accuracy and power in a space saving size ideal for cross dado jobs up to 36 inches.

As of 11/16/2020, the gauging system and dust kit are standard equipment on this machine. Optional accessories include an extension table, air clamps, and a vacuum.

The Gauging System is a multiple stop system for the TR2 Table Router. The system has an embedded gauge with adjustable, flip down stops for cutting different lengths while the dust kit connects your router with your vacuum or dust collection system.

Product demonstration

Standard Equipment

Specifications

| Weight | 285 lbs |

|---|---|

| Dimensions | 45 × 18 × 45 in |

| Max. Crosscut |

36'/910mm |

| Max. Rip Cut |

Unlimited |

| Max. Cut Thickness |

1 3/4'/45mm |

| Cut Accuracy, Straight and Square |

1/64'/.4mm |

| Motor |

15 amp, 120V |

Documents

Product manual

Product parts

TR2 Table Router Sheet

What Our Experts Think

- Precision Routing: The Safety Speed TR2 Table Router is designed to provide high-accuracy routing on a variety of materials, offering smooth, clean edges and intricate cuts for woodworking and cabinetry projects.

- Heavy-Duty Performance: Built with durable industrial-grade materials, the TR2 is made to withstand continuous, high-volume use, ensuring long-lasting reliability and performance in professional environments.

- User-Friendly Operation: The simple controls and quick adjustments make it easy for operators to set up and use, reducing downtime and improving overall shop efficiency.

- Versatile Applications: Ideal for routing wood, MDF, and other sheet materials, making it a versatile tool for shaping, trimming, and cutting various wood products.

- Space-Saving Design: The compact table router design is perfect for shops with limited space, providing powerful routing capabilities without taking up unnecessary floor space.

- Increased Productivity: Speeds up the routing process, ensuring high-quality results in less time, helping to streamline production in cabinetry and woodworking shops.

Q&A

Q: What is the Safety Speed TR2 Table Router?

A: The TR2 is a heavy-duty, precision tabletop router designed for routing, shaping, and edge profiling wood and composite materials in professional woodworking environments.

Q: What are the key features of the TR2 Table Router?

A: The TR2 features a powerful motor, adjustable speed settings, an easy-to-use control panel, and a sturdy table design for accurate routing, making it suitable for various edge work and intricate cuts.

Q: What materials can the TR2 Table Router handle?

A: The TR2 can handle wood, MDF, plywood, and composite materials, making it ideal for cabinetry, furniture making, and custom woodworking projects.

Q: How does the TR2 improve routing accuracy?

A: The TR2 provides precise control over cutting depth and speed, allowing for detailed and consistent edge profiles, grooves, and other routed features on a variety of materials.

Q: Is the TR2 suitable for high-volume production?

A: Yes, the TR2 is designed for both small-scale and high-volume production, offering durability and efficiency for professional woodworking shops.

Q: What safety features are included with the TR2?

A: The TR2 includes safety guards, emergency stop buttons, and other protective mechanisms to ensure safe operation during use.

Q: Is the TR2 Table Router easy to maintain?

A: Yes, the TR2 is designed for easy maintenance, with accessible components for cleaning, lubrication, and servicing, ensuring long-term reliable performance.

Maintenance Tips

-

Clean After Use: After each use, remove any dust, debris, and material buildup from the router table, cutting area, and surrounding surfaces. Use a soft cloth, air compressor, or vacuum to keep the router clean.

-

Inspect and Maintain Router Bits: Regularly check the router bits for dullness, chips, or wear. Replace or sharpen bits as necessary to maintain precision and avoid overloading the motor.

-

Lubricate Moving Parts: Lubricate the moving components, such as the feed mechanism, sliding rails, and height adjustment system, to reduce friction and ensure smooth, accurate operation. Use the recommended lubricant to maintain optimal performance.

-

Check Fasteners and Alignment: Inspect all screws, bolts, and fasteners to ensure they are tight and secure. Check the alignment of the router table, including the fence and height adjustment, to ensure precise routing results.

-

Examine the Feed System: Inspect the feed rollers, conveyor, and other components for wear and ensure they are operating smoothly. Replace or adjust parts if needed to ensure even feeding and consistent cuts.

-

Dust Collection System: Regularly check and clean the dust collection system, including hoses and filters. Clear any blockages to ensure proper airflow and efficient dust removal.

-

Inspect Electrical Components: Check the electrical wiring, motor, switches, and connections for wear or damage. Make sure all components are securely connected, and ensure proper grounding.

-

Monitor Motor Performance: Listen for any unusual noises or signs of overheating. Keep the motor ventilated and clean to ensure proper cooling and efficient performance.

-

Check Router Table Settings: Regularly verify that all settings (such as depth, speed, and fence positioning) are properly adjusted for each project. Recalibrate the router table as needed to ensure precision.

Related Products

- Choosing a selection results in a full page refresh.