Get In Touch +1 (888) 575-2099

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

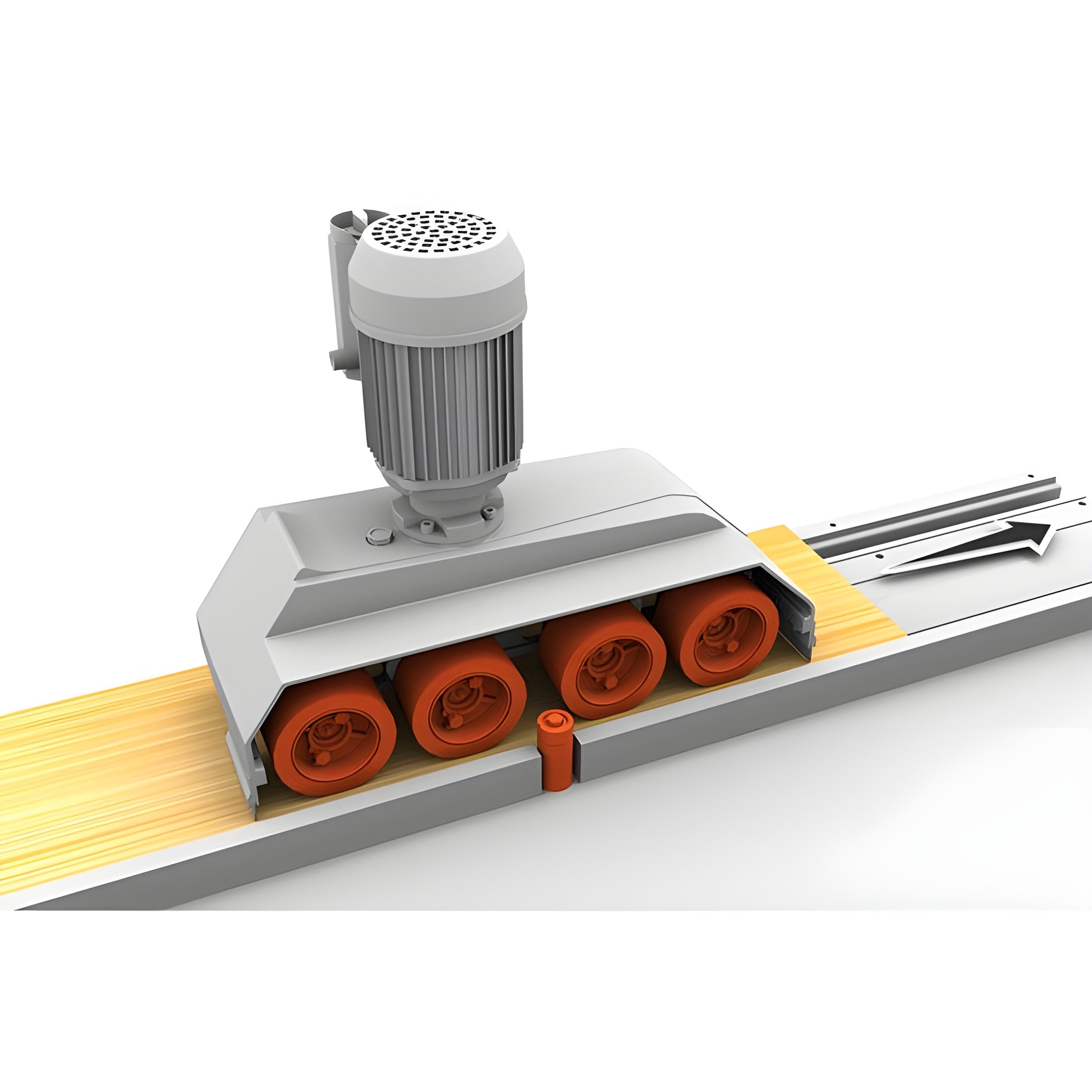

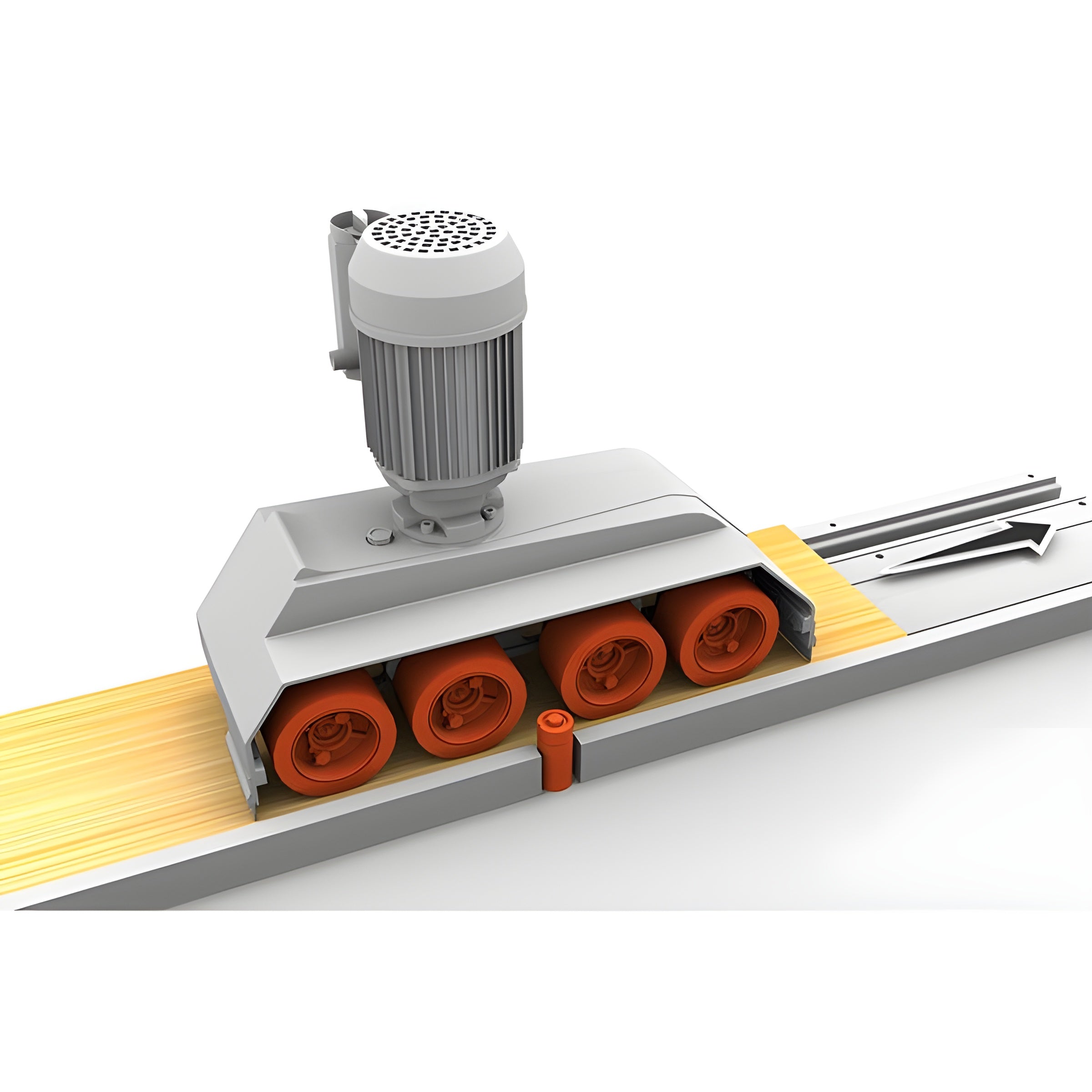

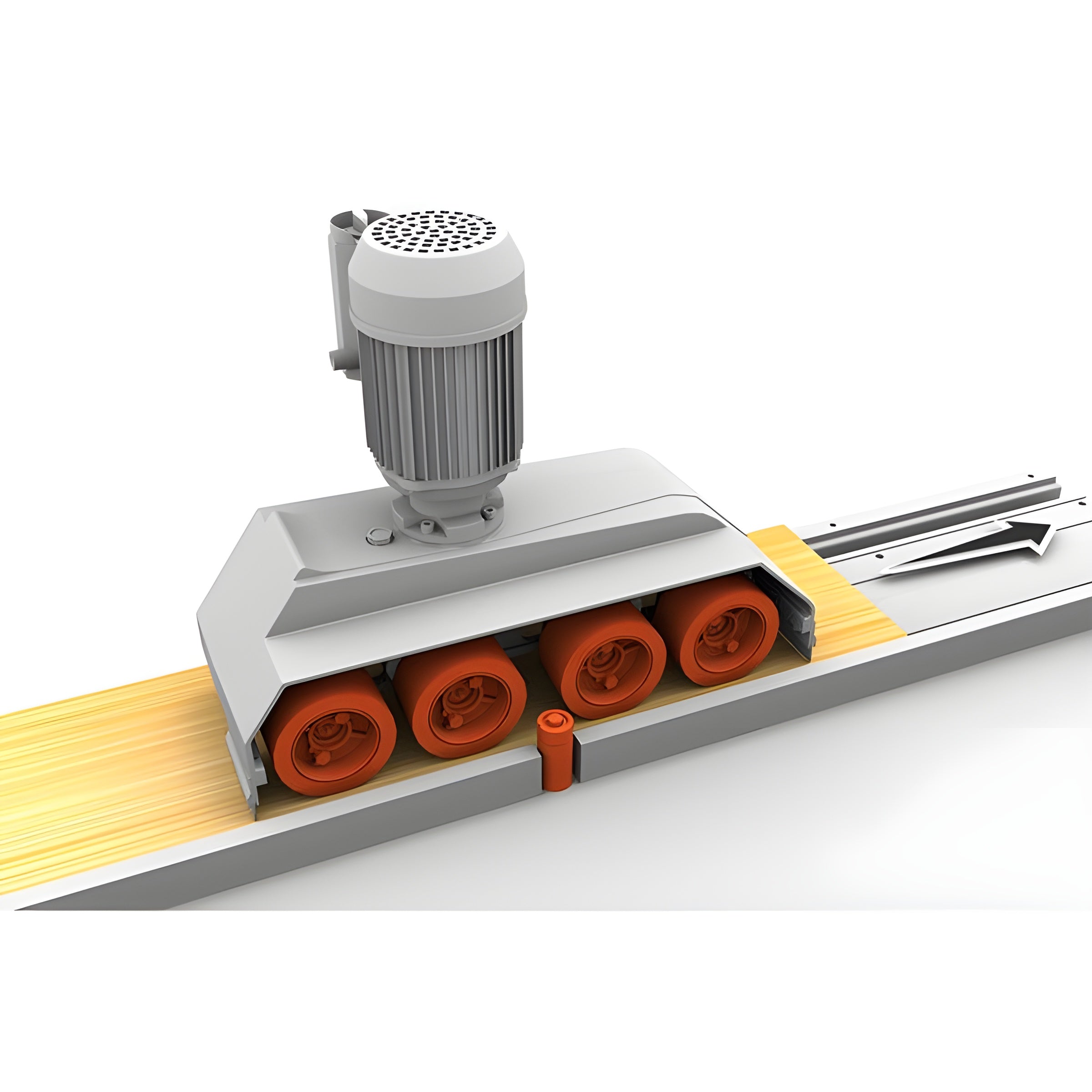

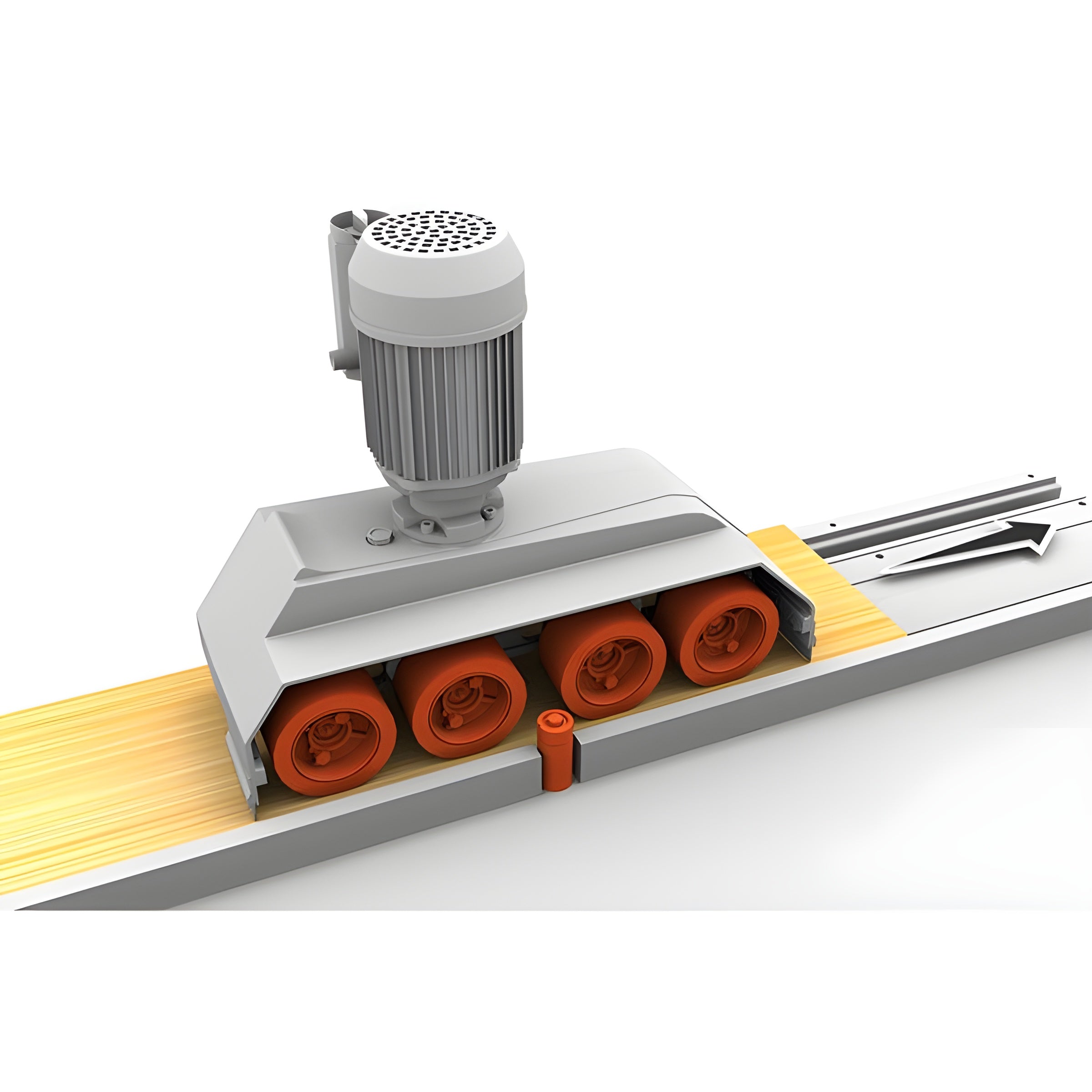

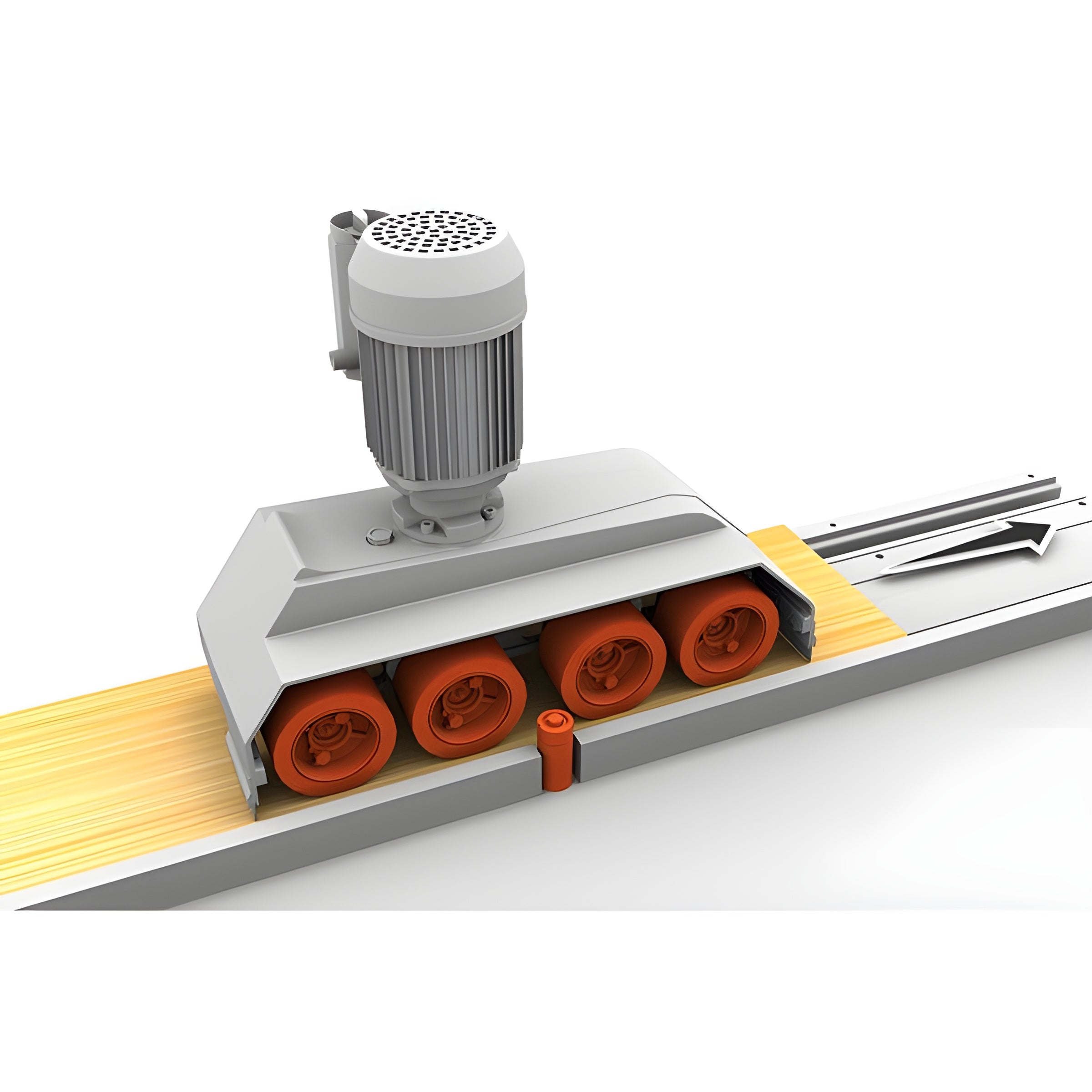

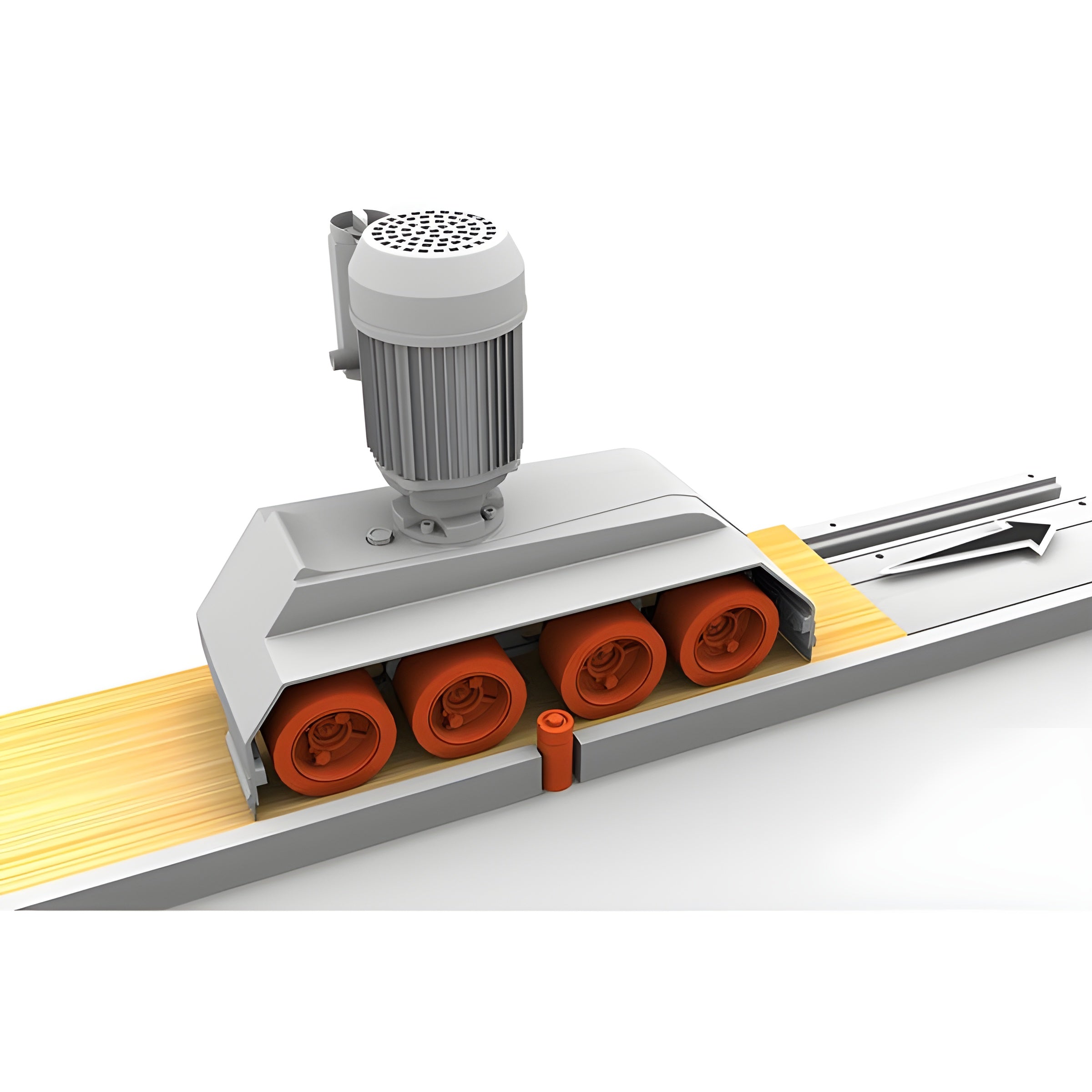

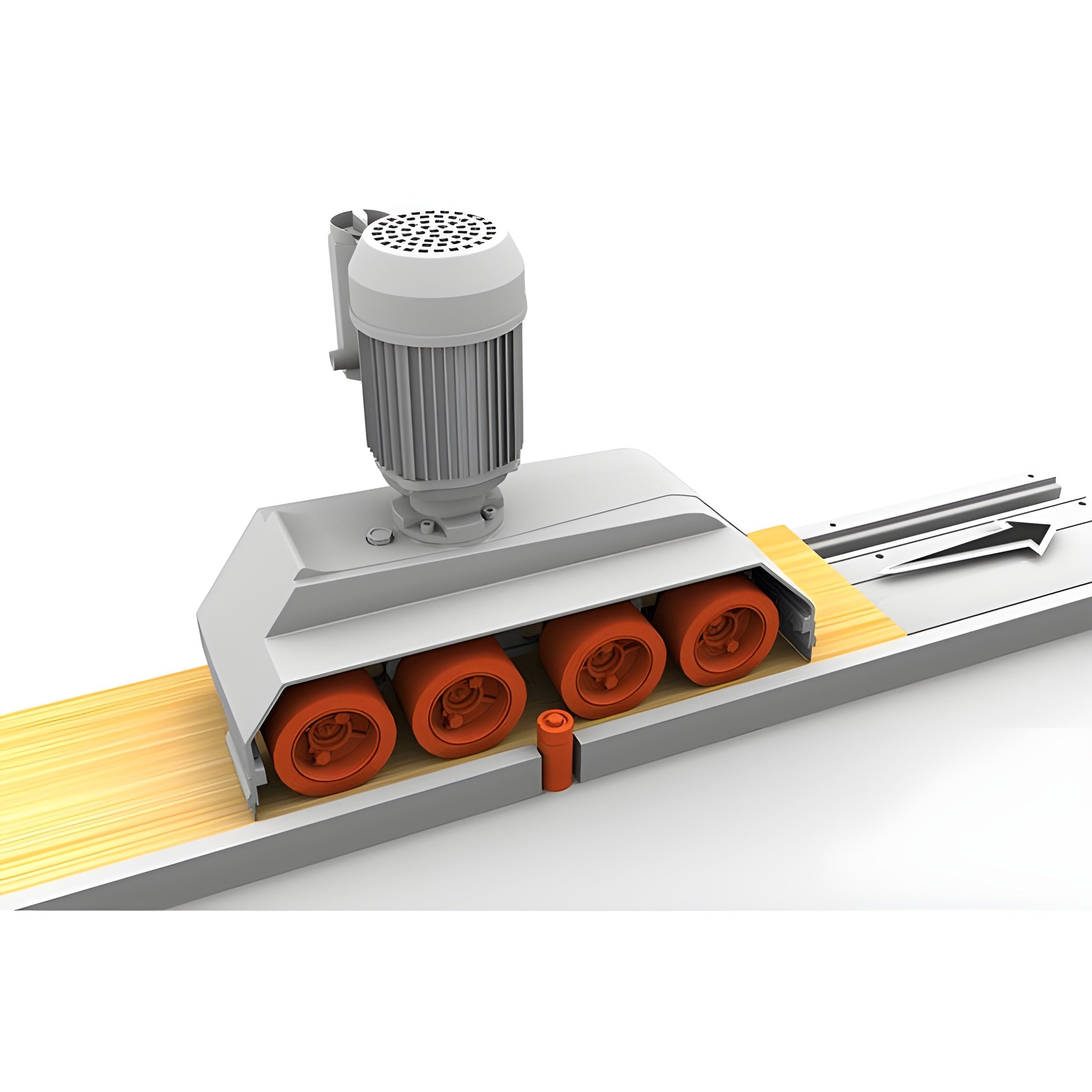

Steff 2048 Power Feeder - STEFF-2048-230v1

The Steff 2048 is an accident prevention device for the safe and correct feeding of classic machines. It eliminates the need for you to put your hands near the tool, allowing you to work safely.

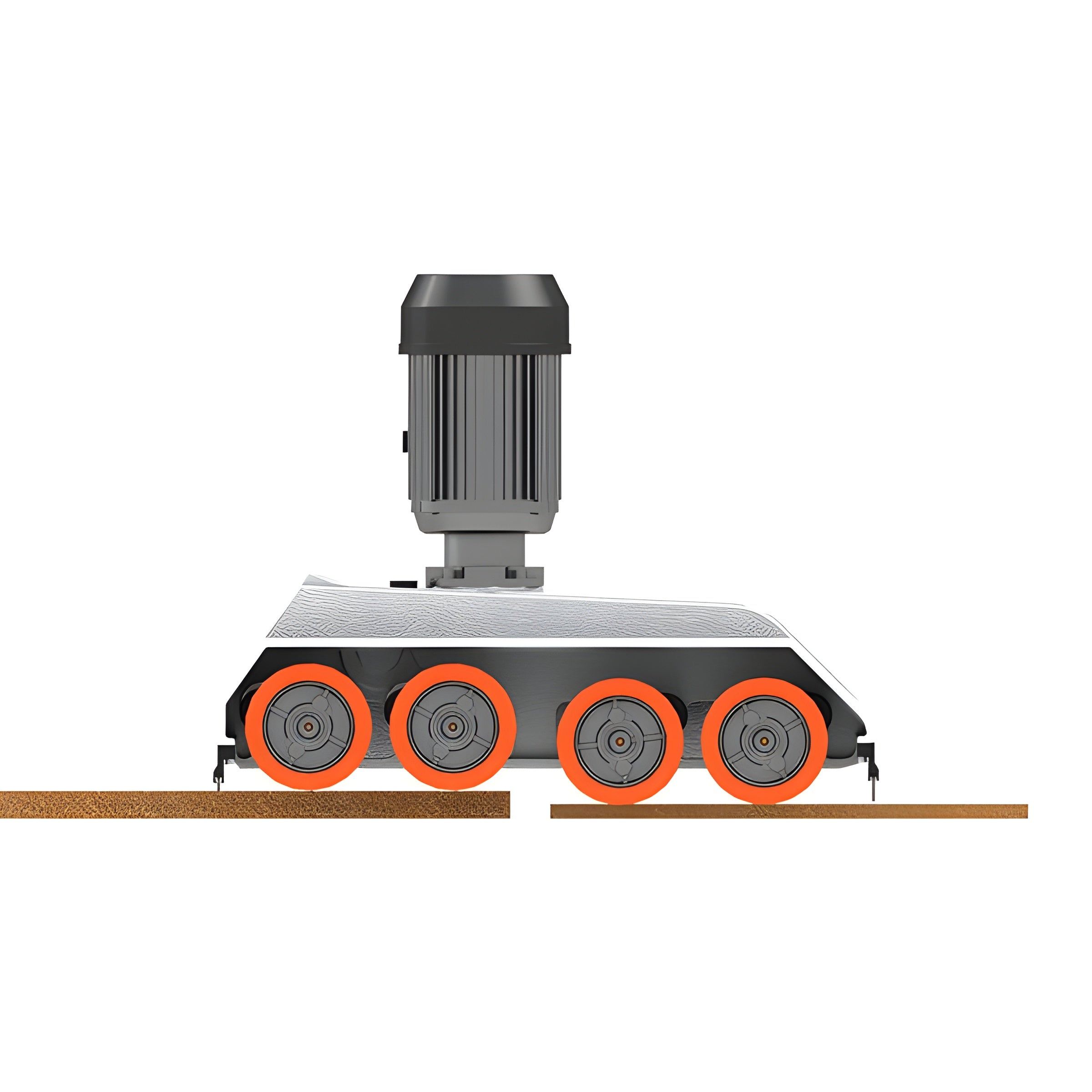

This model features 4 rollers -2 that perfectly hold the incoming piece and 2 that keep it outgoing. It is ideal for dragging medium-sized pieces.

Obtain 8 total speeds of 6-13-18-21-36-42-54-102 FPM. The gearbox contains speed settings of 1 and 2 for both forward and reverse motion. These speeds can be doubled by a turn of the gear lever.

Patented Feeder Grip Technology and 50 Shore wheels allow for optimal grip and maximum adherence. The calibrated suspension of the 20 mm wheels allows you to drag pieces of different thickness without further adjustments.

The universal support stand allows you to position the feeder in a variety of configurations. Steff Power Feeders keep your hands and fingers safe and away from blades and cutters. Additionally, as the rollers/belts hold the stock in place, kickback possibilities are practically eliminated. The finish cut of your product is uniform and free of defects associated with uneven stop/start feeding of your piece.

Feature

-

Work in safety: the operator does not bring hands near the tool

-

High quality workmanship due to constant workpiece feed

-

Optimal feeding by adjusting the speed

-

Adaptability to all processing needs

-

Made in Italy

Specifications

| Net weight: | 163 lbs. |

|---|---|

| Roller material: | 50 Shore Rubber |

| Speeds: | 8 fixed speeds (6-13-18-21-36-42-54-102 ft/min) |

| Wheels: | 3 (diameter / thickness 4.7"x 2.4") |

| Single Phase motor: | 0.7 HP or 0.5 KW |

| 3-Phase motor: | 1HP or .75 KW |

| Machine body material: | cast aluminum machined on a high precision center |

| Chainguard material: | Corrosion-resistant steel |

What Our Experts Think

The Steff 2048 Power Feeder (STEFF-2048-230v1) is a high-quality, industrial-grade material feeding solution designed for precision and efficiency in woodworking and manufacturing operations. Here's why it’s a top recommendation:

- Consistent, Smooth Feeding: Ensures smooth, consistent material feeding to improve precision and quality during operations such as routing, sanding, and planing, reducing waste.

- Versatile Speed Control: Features multiple adjustable feed speeds, allowing for customization based on material type and project requirements, providing flexibility for diverse applications.

- Heavy-Duty, Durable Construction: Built with robust, long-lasting materials to withstand continuous heavy-duty use, making it perfect for commercial and industrial environments.

- Precise Performance: Delivers accurate, uniform feeding, which is crucial for high-quality results and productivity in demanding tasks.

- User-Friendly Design: Easy to set up and operate, this feeder is designed to be intuitive and simple, even for users new to power feeders.

- Safety and Reliability: Comes with built-in safety features to protect the operator and prevent accidents, offering peace of mind in busy workshop environments.

The Steff 2048 Power Feeder is an excellent choice for high-demand environments that require reliable, durable, and precise material feeding. Its versatility, robust build, and ease of use make it ideal for professionals looking to improve efficiency and performance in their woodworking or manufacturing processes.

Q&A

Q: What is the Steff 2048 Power Feeder (STEFF-2048-230v1)?

A: A high-performance, durable power feeder designed for woodworking machinery, providing smooth, consistent feeding of materials with a 230V power supply to enhance precision and efficiency during production.

Q: Who is it ideal for?

A: Ideal for professional woodworkers and high-demand workshops that require a powerful, reliable feeder to handle heavy-duty woodworking tasks with accuracy and consistency.

Q: What makes it unique?

A: The Steff 2048 offers a 230V motor for high-performance, adjustable feed rates for various materials, and a sturdy build to ensure reliability and smooth material handling during continuous use.

Q: Is assembly required?

A: Yes, assembly is required, and professional installation is recommended to ensure the feeder is set up properly for optimal performance.

Maintenance Tips

- Clean Regularly: Wipe down the unit, including the feed rollers, drive system, and surrounding areas, with a soft cloth to remove dust, debris, and grease buildup.

- Inspect Weekly: Check for wear on rollers, gears, and belts. Ensure they are securely fastened and free from damage or misalignment. Tighten or replace parts as necessary.

- Lubricate Moving Parts: Apply the recommended lubricant to the rollers, gears, and moving components every 1-2 months to ensure smooth, efficient operation and reduce wear.

- Check Electrical Connections: Inspect all electrical wiring and connections for wear, fraying, or loose connections to prevent power issues and malfunctions.

- Monitor Feed Performance: Ensure the feeder is operating consistently and evenly. Adjust the tension or alignment if the feeding mechanism shows signs of inconsistency.

- Prevent Overheating: Keep the feeder in a well-ventilated area to avoid overheating, which could lead to motor failure or damage to components.

- Protect from Moisture: Store the power feeder in a dry environment to prevent rust or damage to electrical parts.

- Annual Servicing: Schedule an annual professional inspection to ensure the unit is functioning optimally and address any potential issues before they impact performance.

Related Products

- Choosing a selection results in a full page refresh.