Get In Touch +1 (888) 575-2099

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

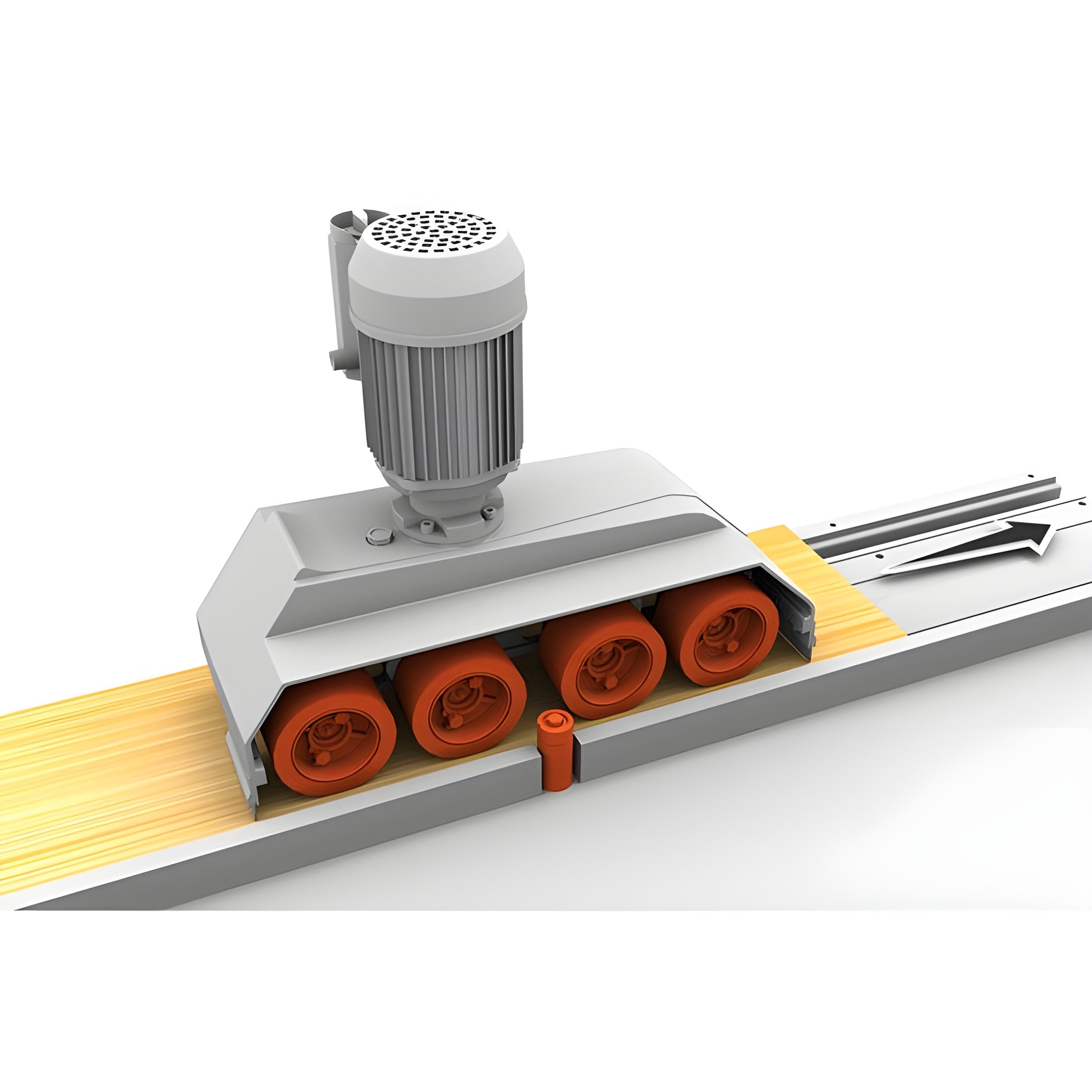

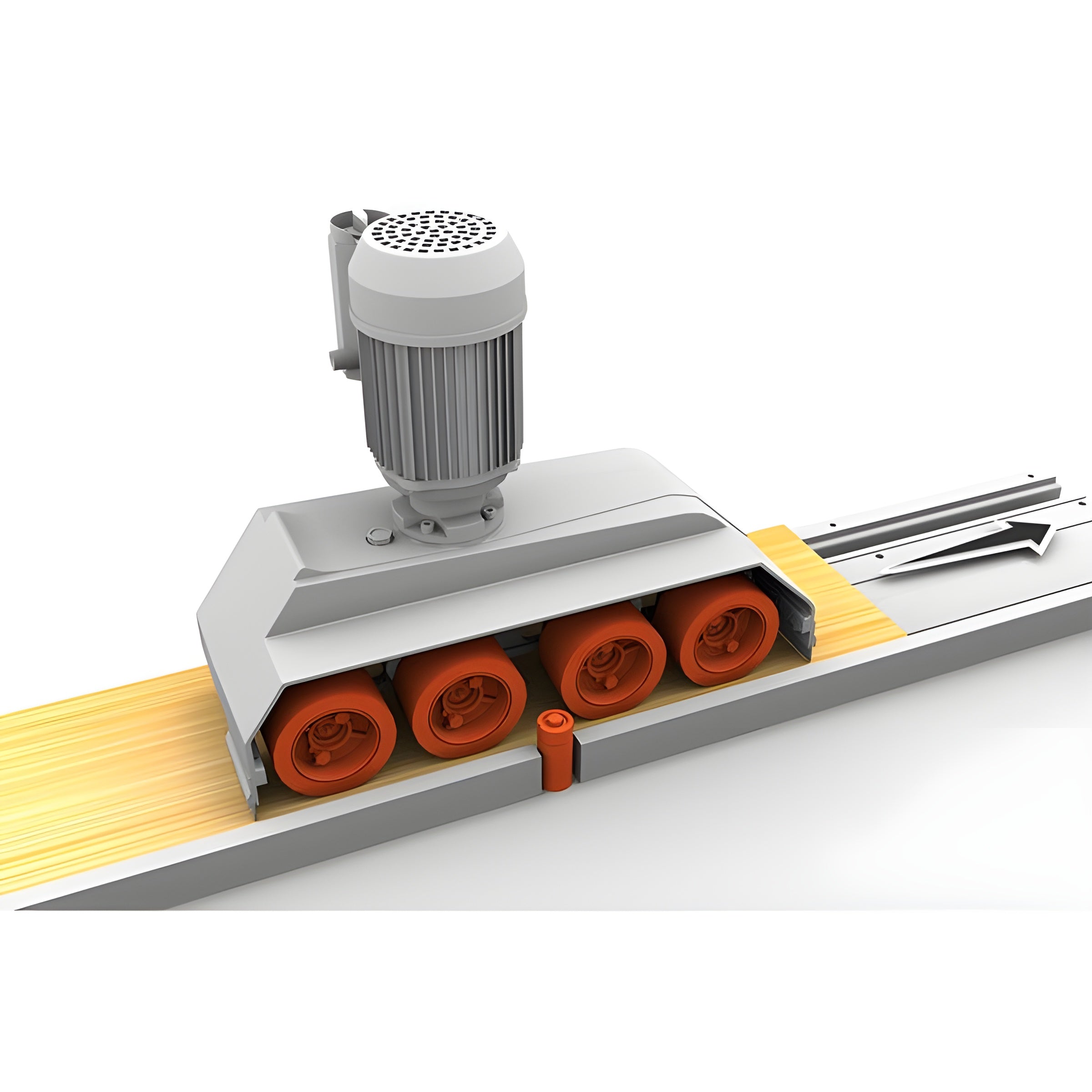

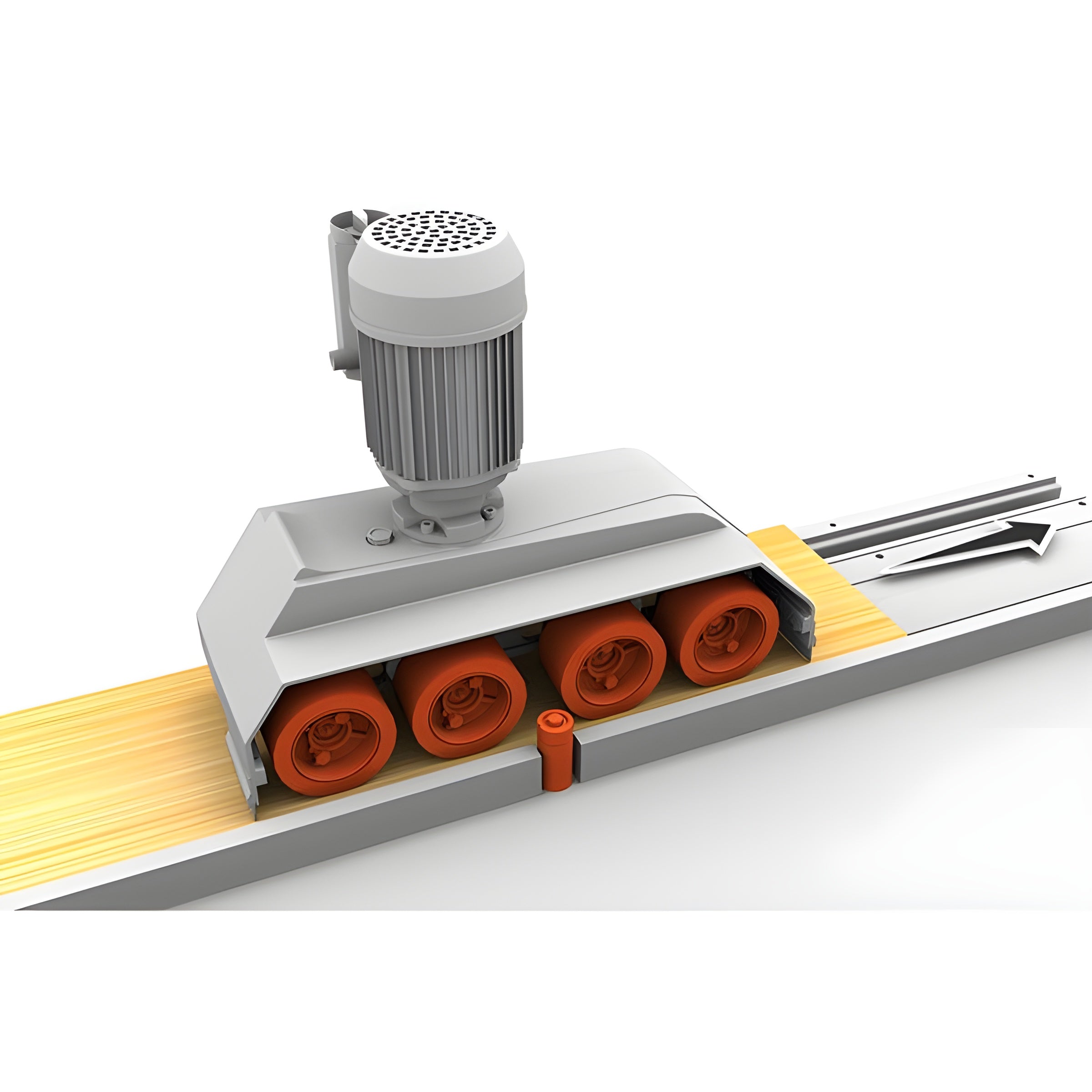

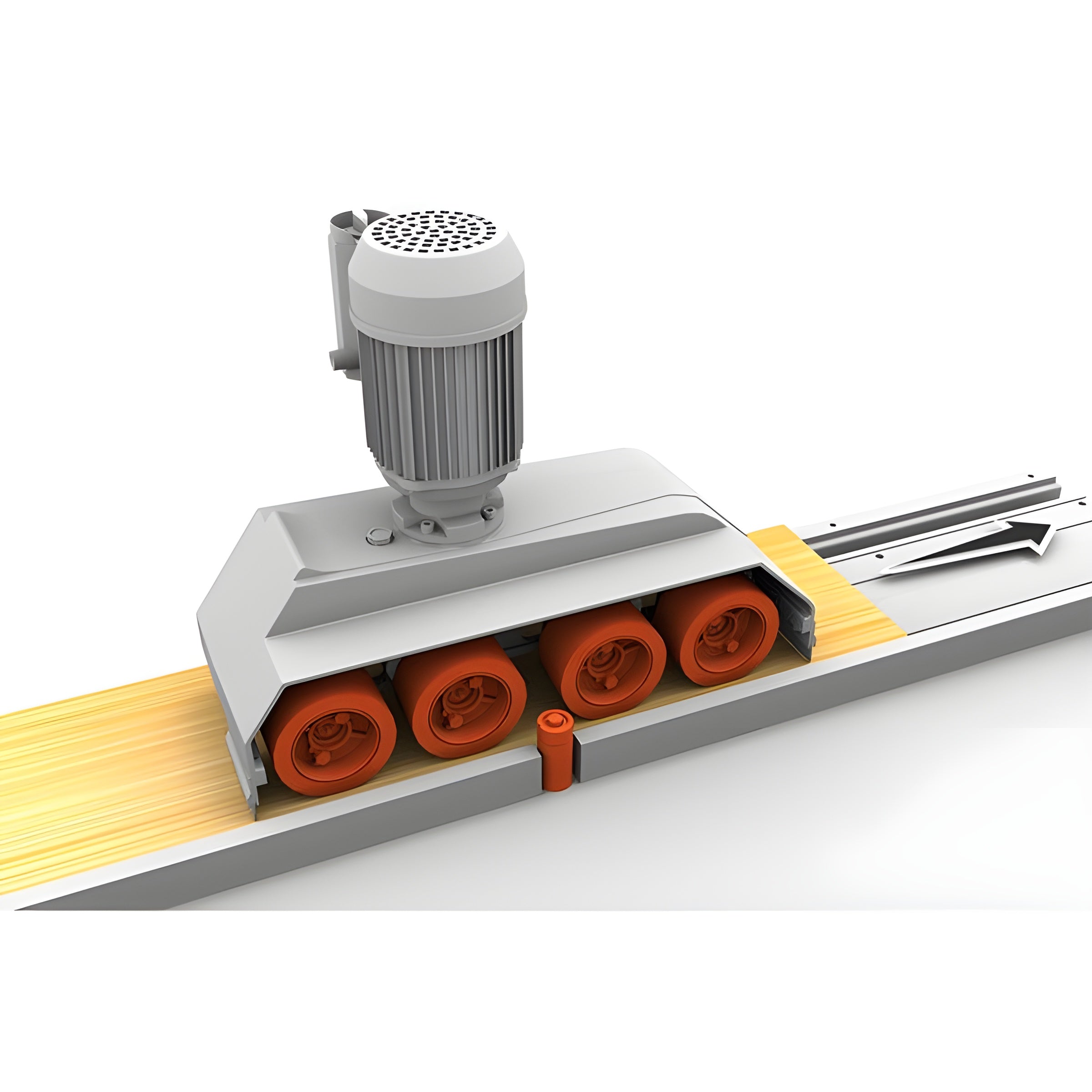

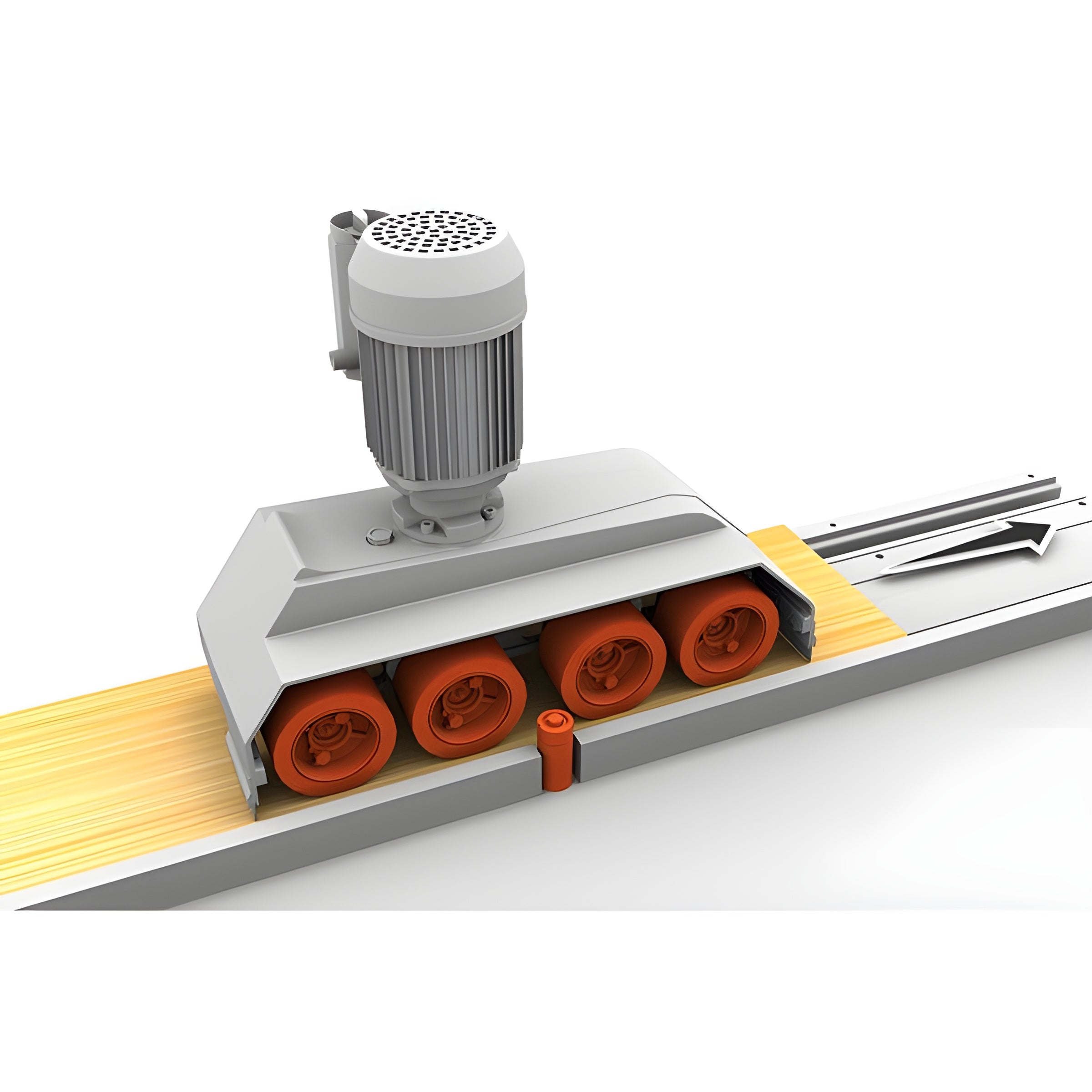

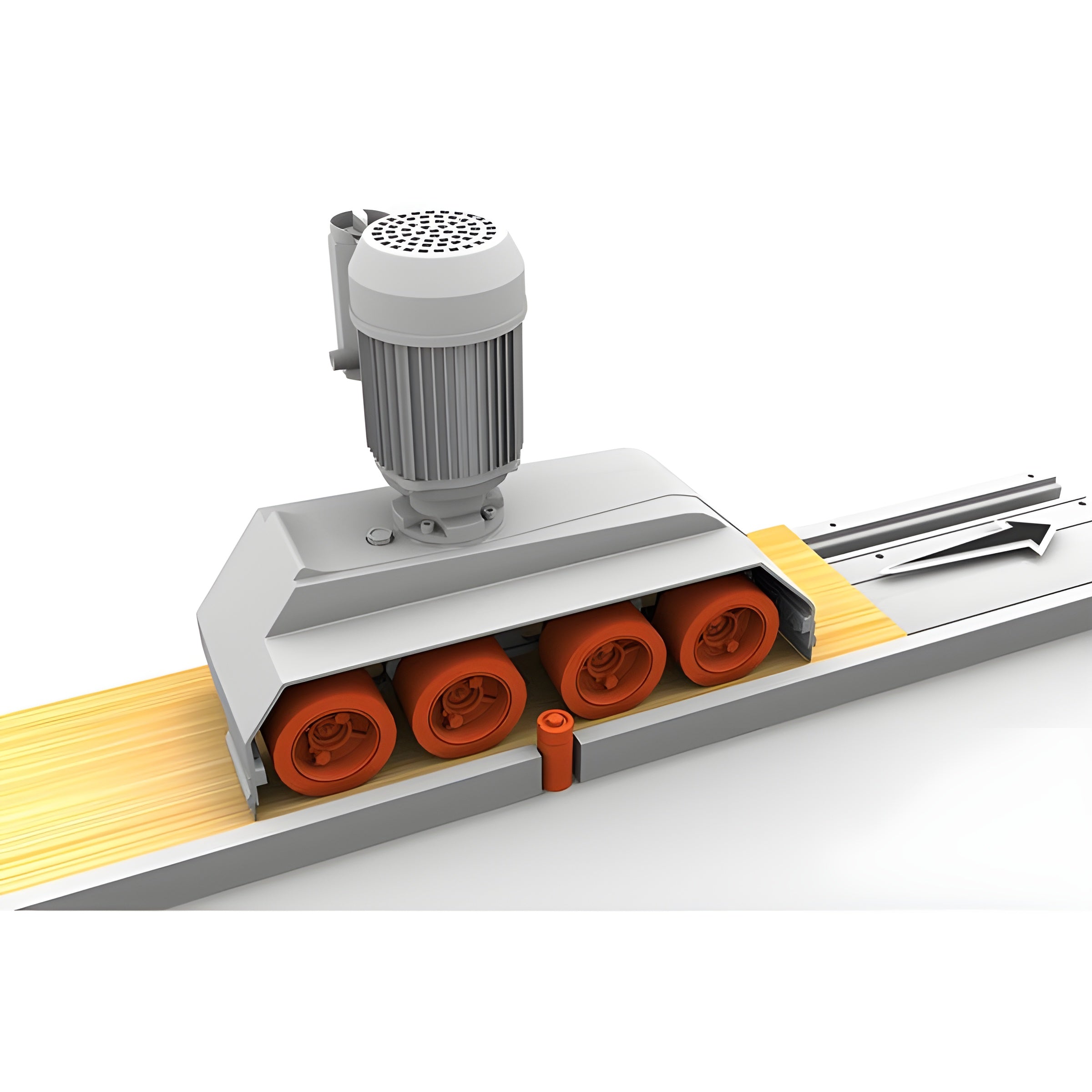

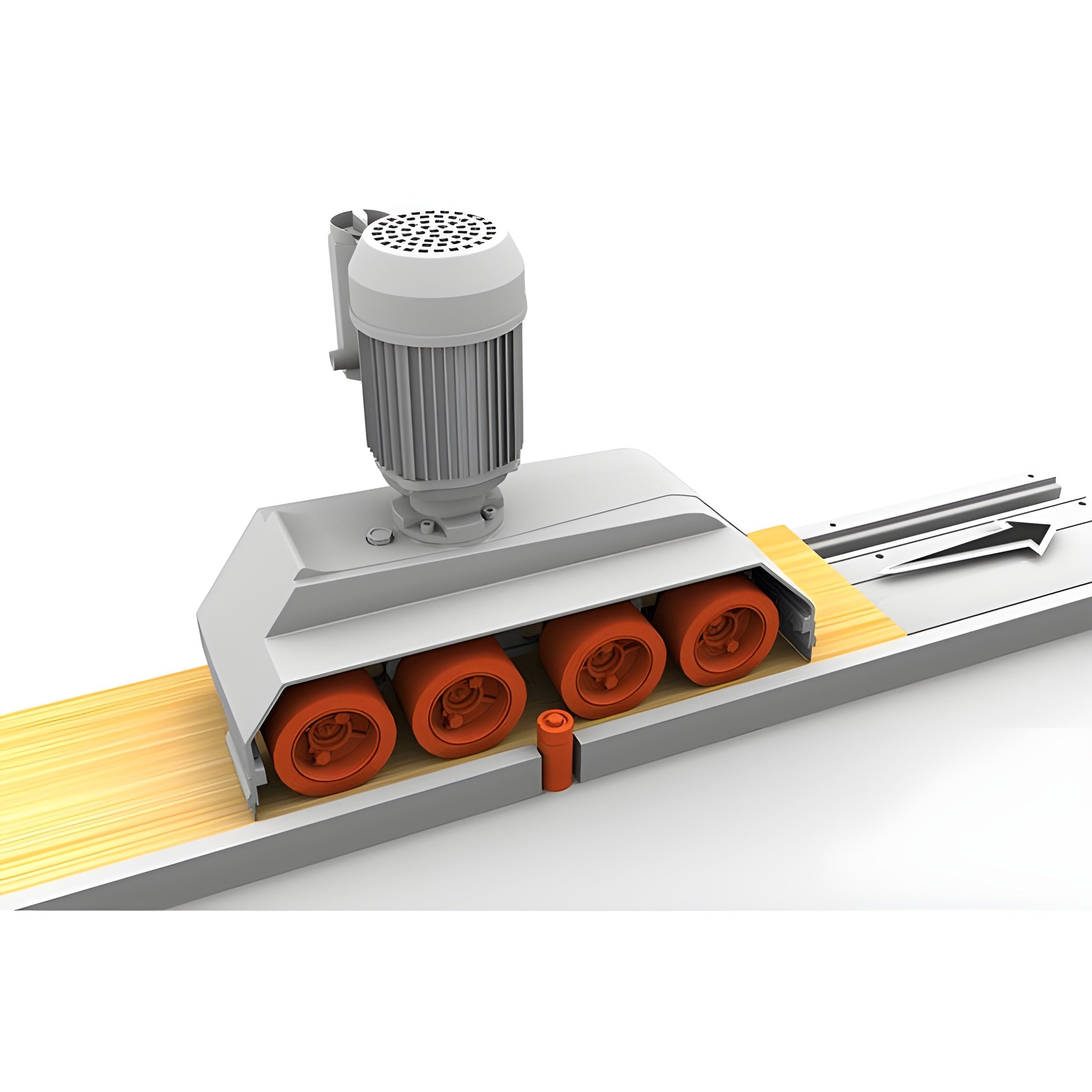

Steff Supersonic 4 Power Feeder - STEFF-SUPERSONIC4

The Steff Supersonic 4 is an accident prevention device for the safe and correct feeding of classic machines. It eliminates the need for you to put your hands near the tool, allowing you to work safely.

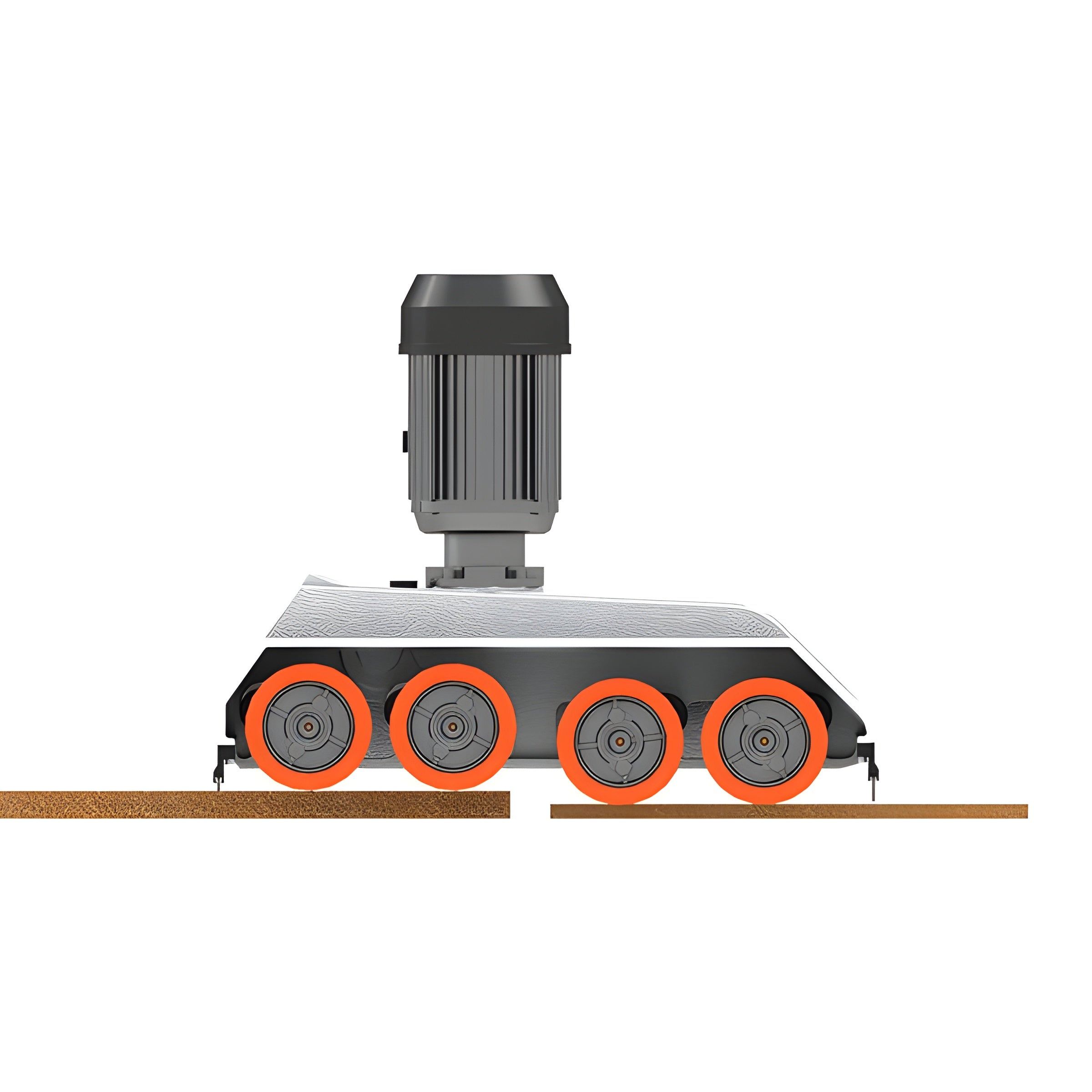

Achieve high quality workmanship with the constant feed of the piece. This model features 4 rollers -2 that perfectly hold the incoming piece and 2 that keep it outgoing. It is ideal for dragging medium-sized pieces.

The Supersonic 4 model features a wide range of variable speeds up to 82 FPM. Your speed is always electronically displayed on the screen. This model is ideal for those who have to change the type of processing often. You can change the direction of the piece by a simple press of a button.

The universal support stand allows you to position the feeder in a variety of configurations. Steff Power Feeders keep your hands and fingers safe and away from blades and cutters. Additionally, as the rollers/belts hold the stock in place, kickback possibilities are practically eliminated. The finish cut of your product is uniform and free of defects associated with uneven stop/start feeding of your piece.

This machine is endlessly adaptable. The calibrated suspension of the 20 mm wheels allows you to drag pieces of different thickness without further adjustments. Protective brushes are mounted on both sides of the feed to prevent accidents. The 3-Phase motor is economically sound and offers maximum power and efficiency.

Feature

-

Work in safety: the operator does not bring hands near the tool

-

3-Phase motor offers maximum power and efficiency

-

High quality workmanship due to constant workpiece feed

-

Optimal feeding by adjusting the speed

-

Adaptability to all processing needs

-

Made in Italy

Specifications

| Net weight | 147 lbs |

|---|---|

| Roller material | 50 Shore Rubber |

| Speeds | Variable speeds up to 82 ft/min |

| Wheels | 4 (diameter / thickness 4.7"x 2.4") |

| 3-Phase motor | 1 HP or 0.75 KW |

| Machine body material | cast aluminum machined on a high precision center |

| Chainguard material | Corrosion-resistant steel |

What Our Experts Think

The Steff Supersonic 4 Power Feeder (STEFF-SUPERSONIC4) is a high-performance tool designed to enhance safety, precision, and efficiency in woodworking. Here's why it's a must-have:

- 4 Roller Feeding System: Provides consistent and smooth material feeding for accurate and even cuts.

- Adjustable Speeds: Offers multiple speed settings, ensuring optimal feeding for various materials and operations.

- Robust Motor: Delivers reliable power for heavy-duty tasks, making it suitable for professional workshops.

- Adjustable Feed Angles: Allows precise customization for different applications, improving versatility and accuracy.

- Heavy-Duty Construction: Built to withstand rigorous use, ensuring long-lasting durability.

- Enhanced Safety: Keeps hands away from cutting zones, providing a safer woodworking experience.

Q&A

Q: What is the Steff Supersonic 4 Power Feeder?

A: The Steff Supersonic 4 is a high-performance power feeder designed for precision and efficiency in woodworking, ensuring smooth and consistent material feeding.

Q: Why choose this power feeder?

A: It offers reliable performance for professional-grade woodworking tasks, improving productivity and accuracy.

Q: What makes it unique?

A: Its advanced design ensures stable operation, making it a trusted choice for demanding woodworking applications.

Maintenance Tips

- Daily Cleaning: Wipe the feeder's exterior and rollers with a clean cloth to remove dust, debris, and resin.

- Roller Care: Inspect and clean the rollers regularly to ensure proper grip and feeding accuracy. Replace if worn or damaged.

- Lubrication: Periodically lubricate moving parts, such as the adjustment mechanisms and arms, following the manufacturer's guidelines.

- Tighten Components: Check and tighten all bolts, screws, and clamps to maintain stability and precision during operation.

- Inspect Gears and Motors: Regularly inspect the drive gears and motor for signs of wear or damage and address any issues promptly.

Related Products

- Choosing a selection results in a full page refresh.