Get In Touch +1 (888) 575-2099

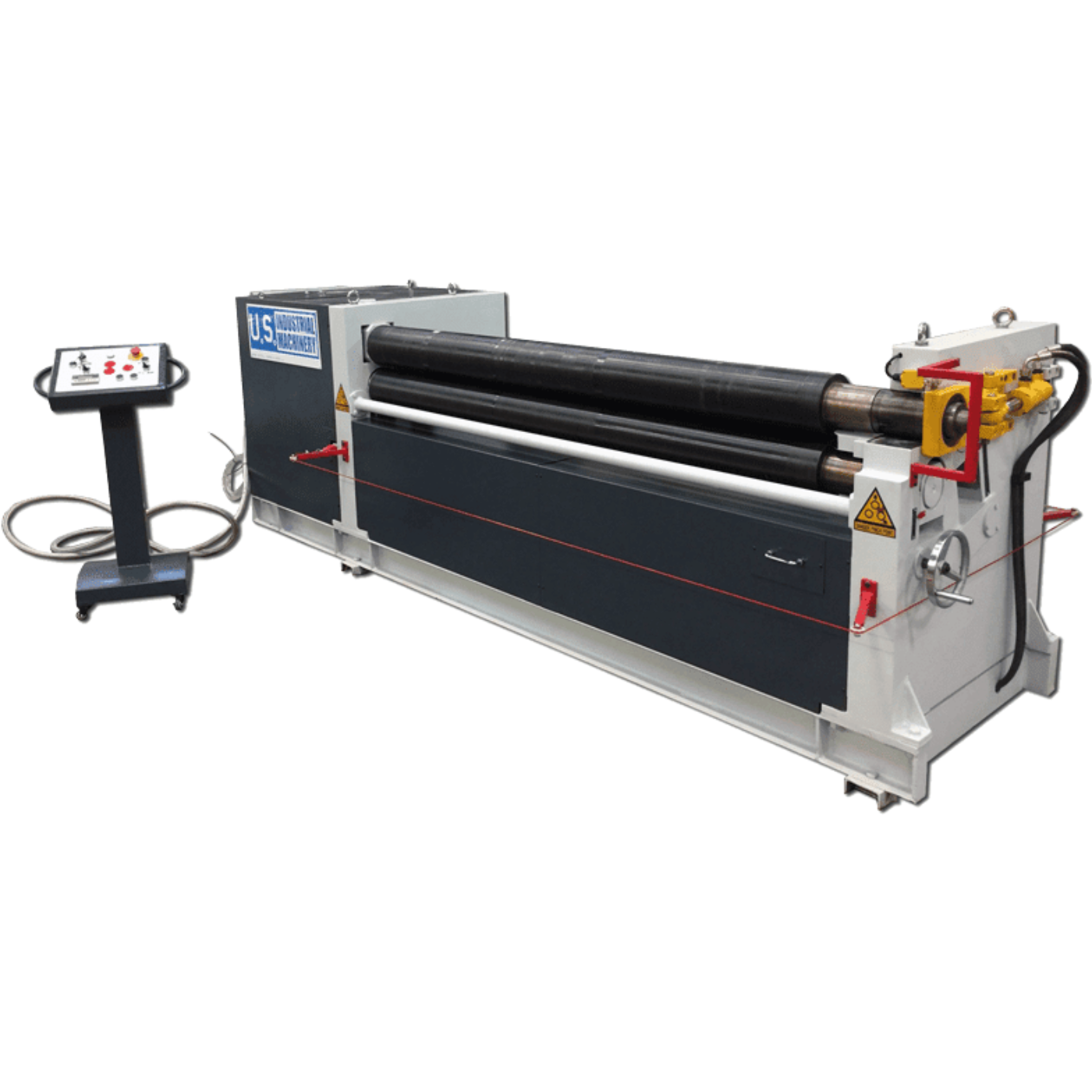

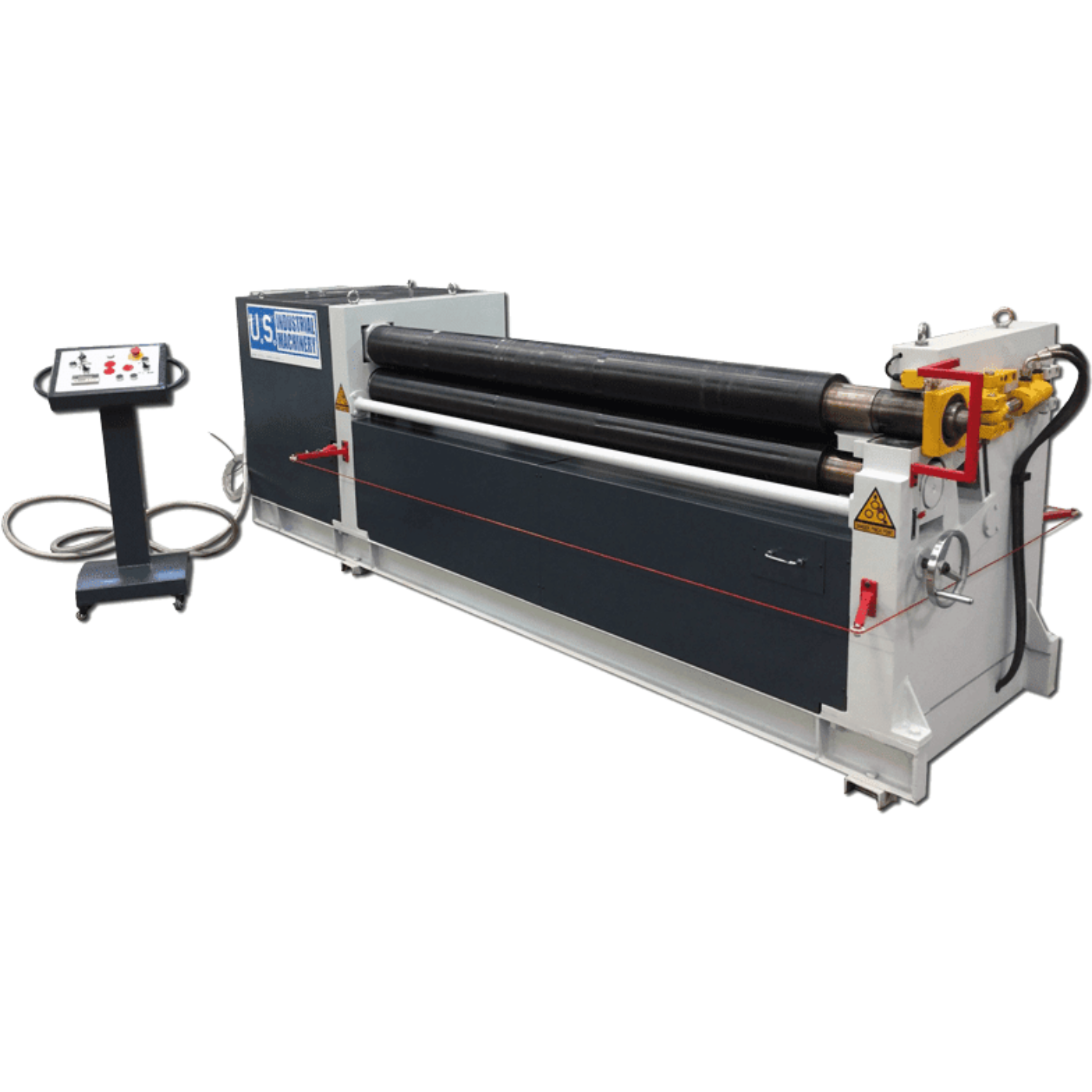

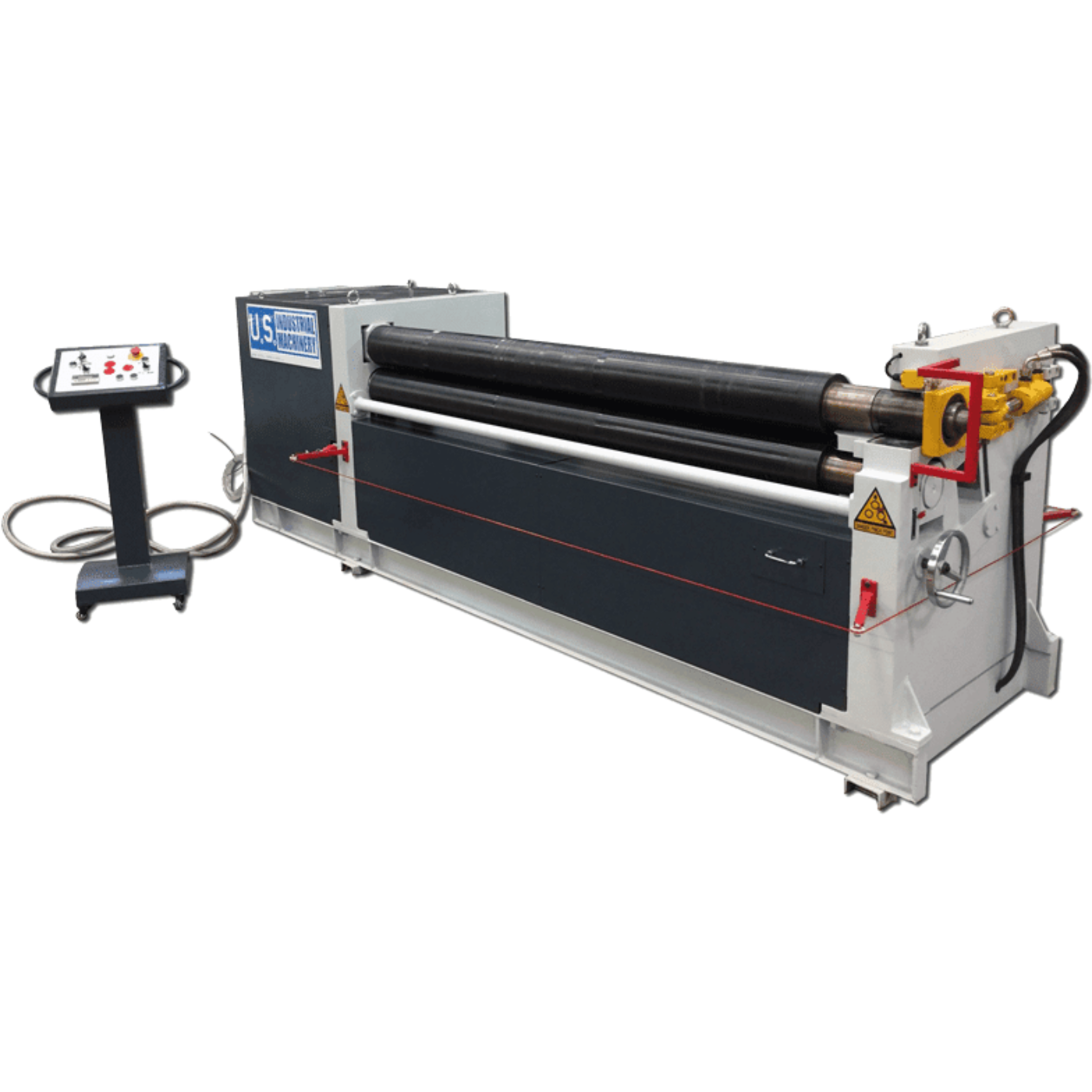

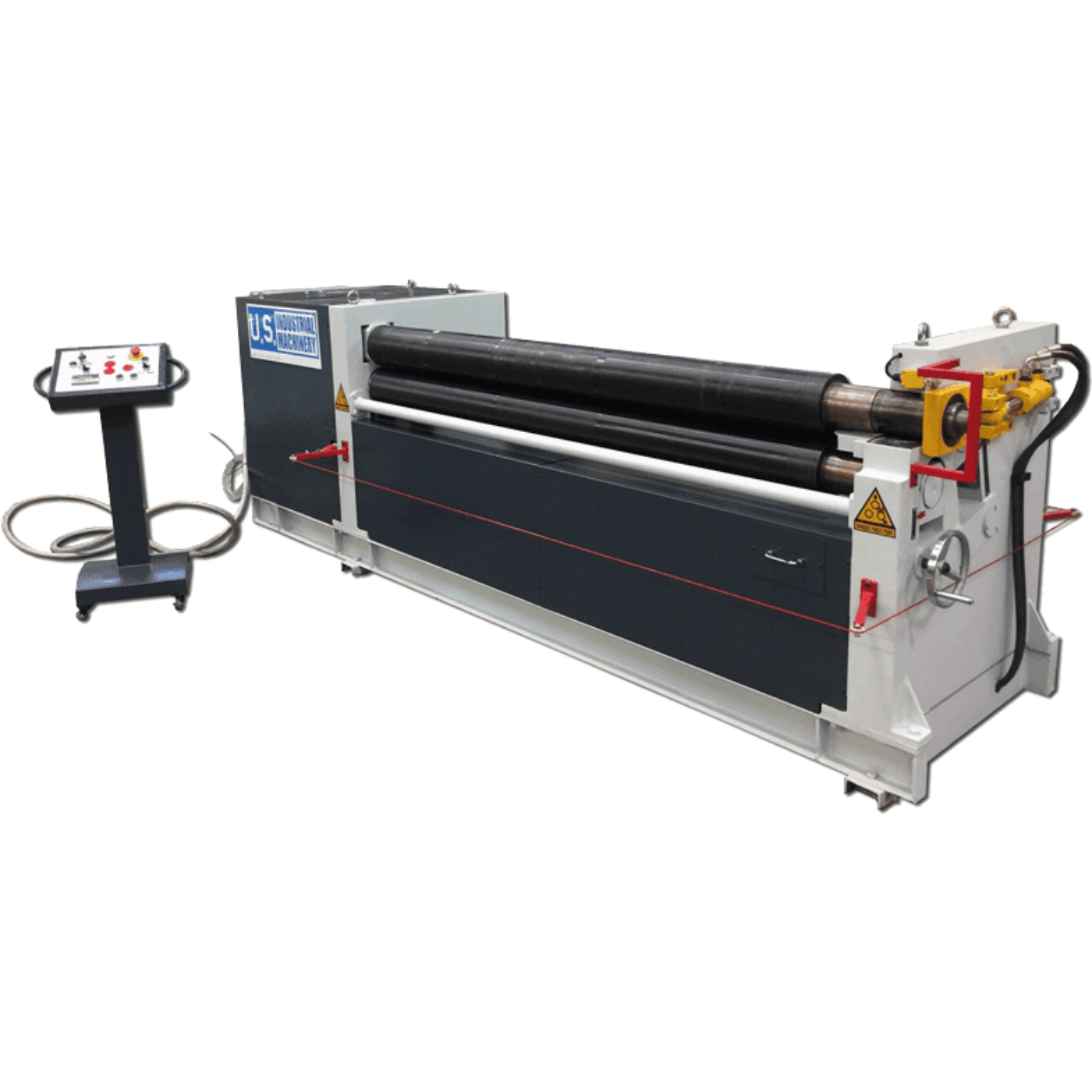

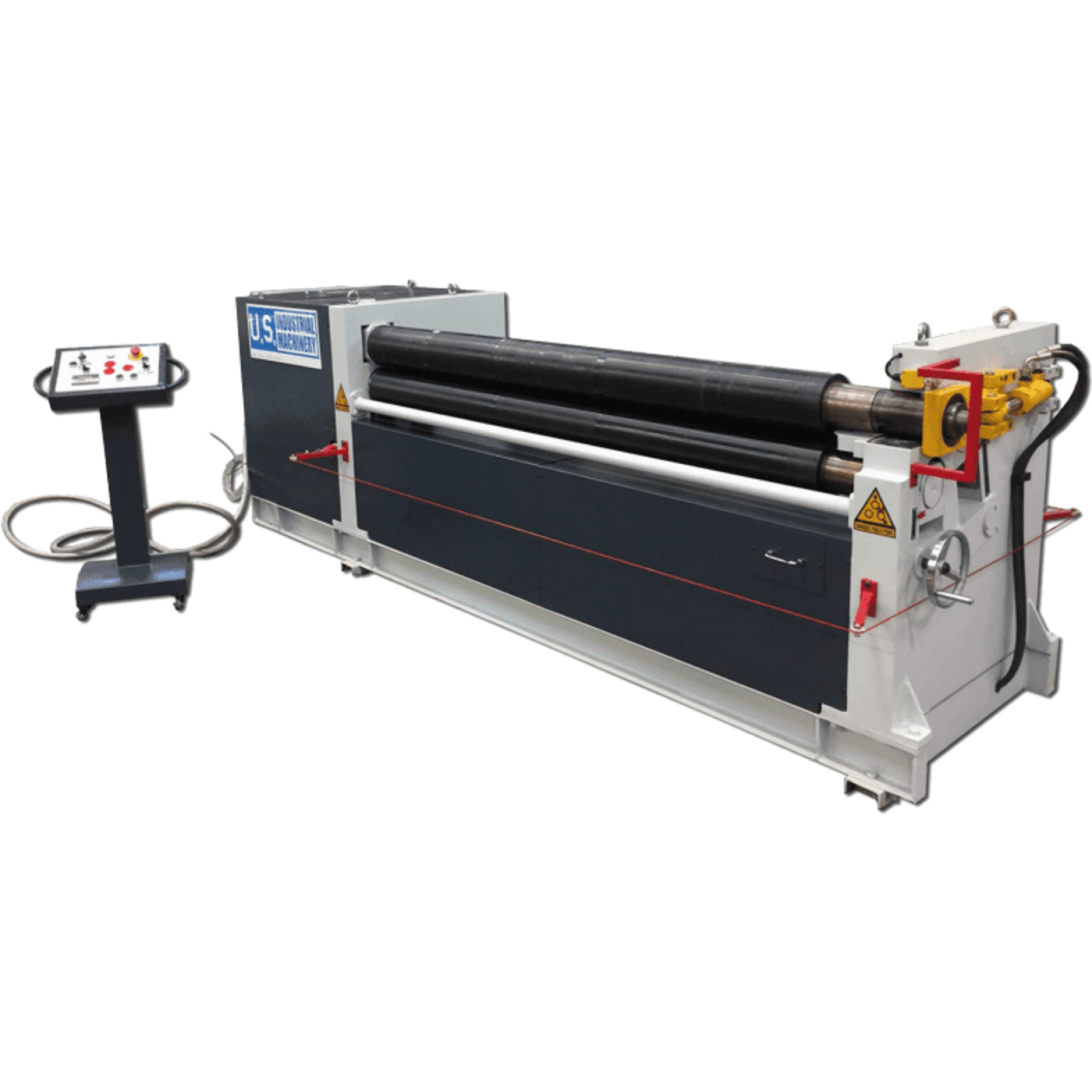

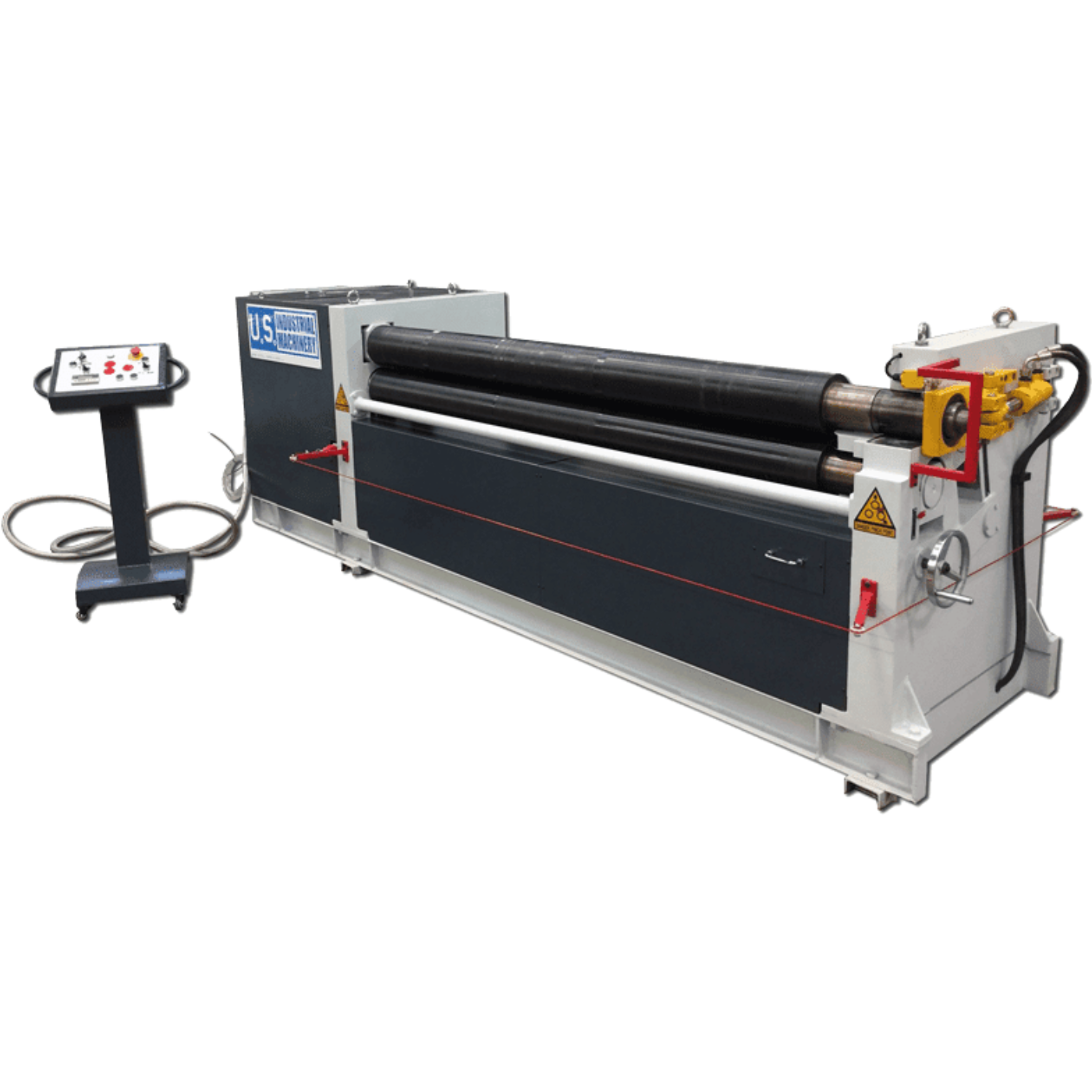

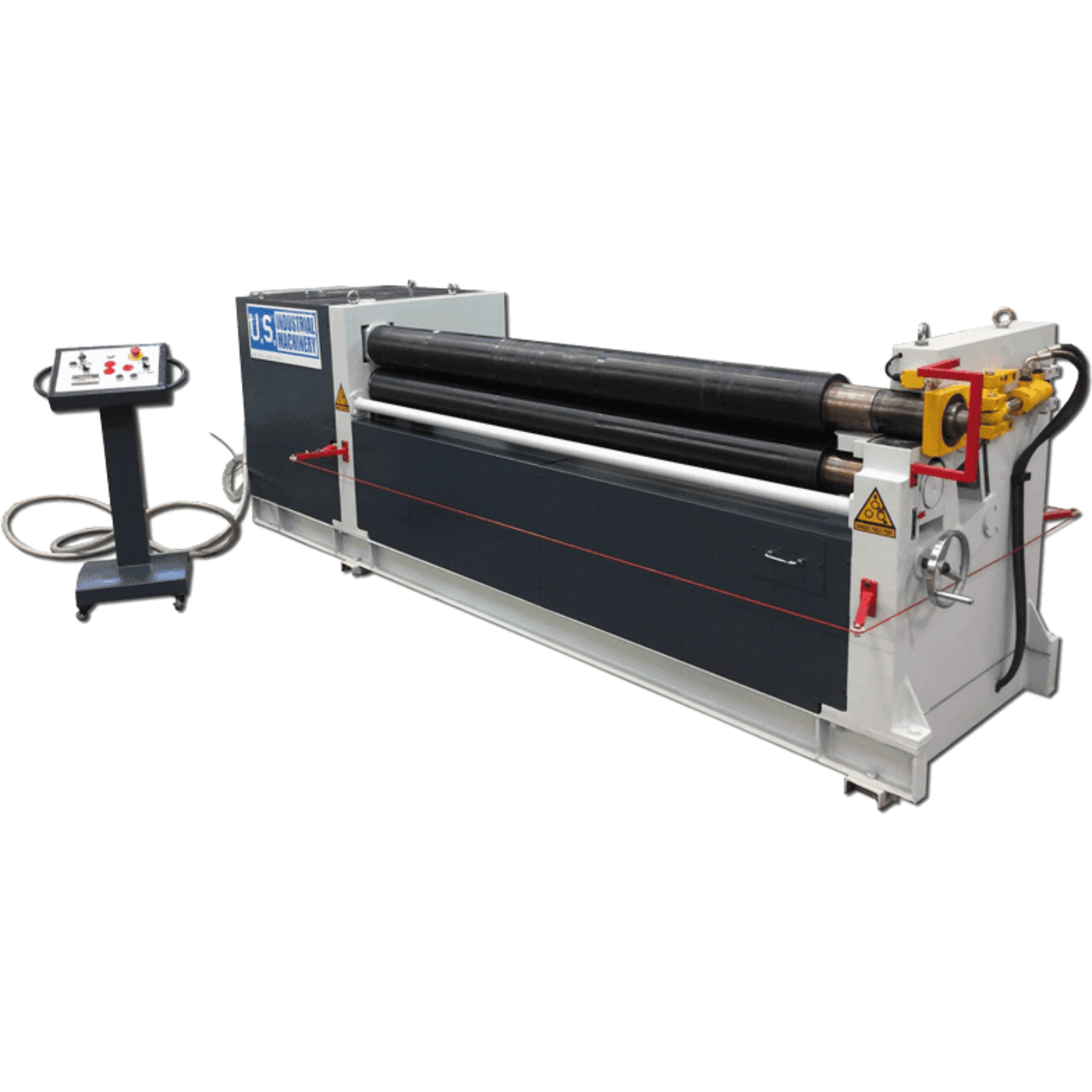

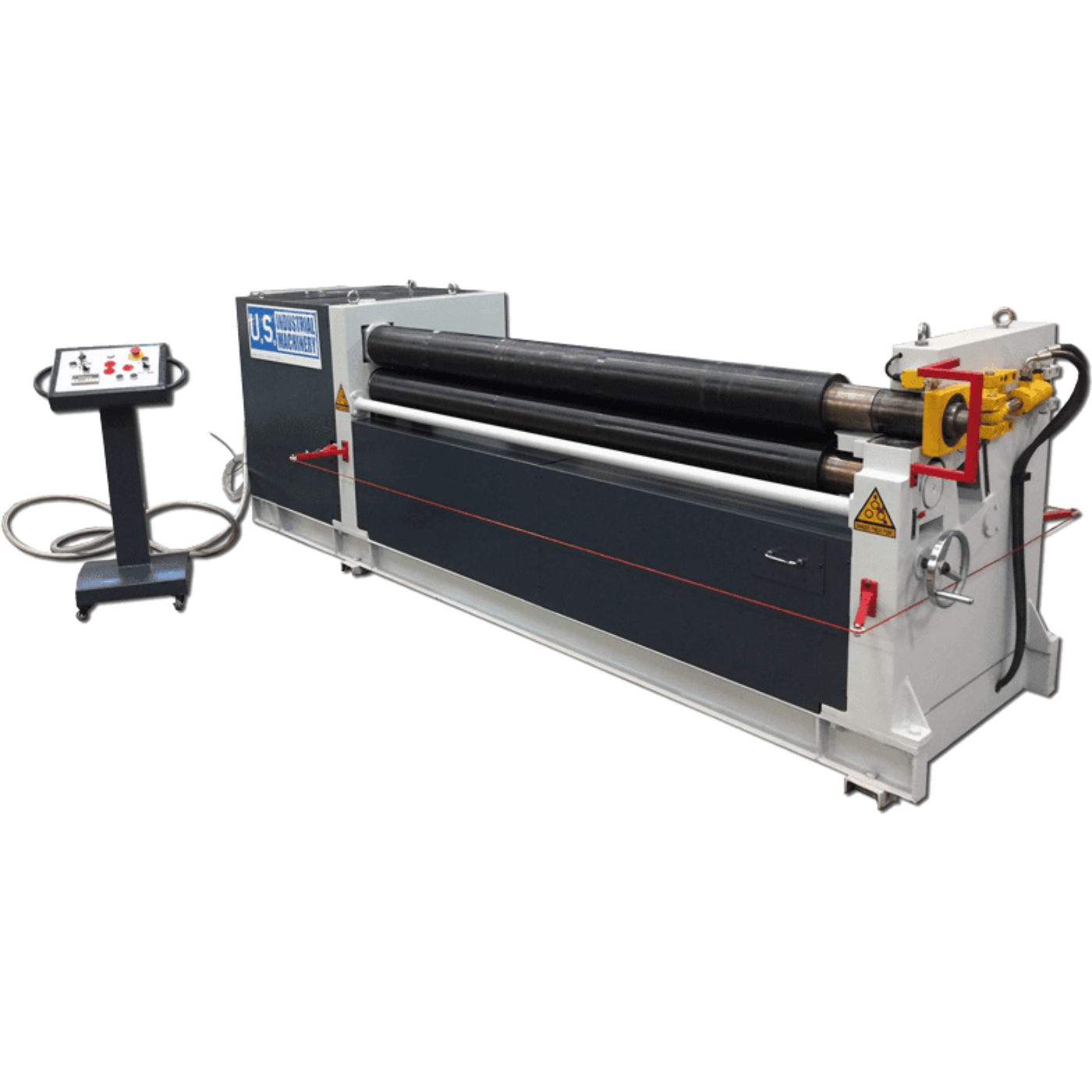

U.S Industrial Machinery Plate Roll, 10’ x 1/4”, Initial Pinch - USR1025

- $48,990.00

$56,340.00- $48,990.00

- Unit price

- per

Expert Support,

Dial +1 (888) 575-2099

Limited Supply,

grab it before it's gone.

Lowest prices,

As low as possible.

All Items are brand New,

Never used.

Recently Viewed Products

Custom-built machines are also available for needs outside of these sizes.

When it comes to high-quality plate roll machines, no one pairs performance with affordability like U.S. Industrial Machinery in Memphis, TN. Our machines go through rigorous testing and quality assurance checks to ensure our customers receive nothing but the best. Every piece of equipment comes with a one-year warranty, and our team offers continuing support to customers for troubleshooting and specification questions throughout the life of your machine for the original purchaser. You’ll always have a U.S. Industrial Machinery specialist available when you need us. Our plate rolling machines are gear-driven and can be adjusted to pinch varying metal thicknesses up to the machine’s capacity. The LED display on the controller shows the position of the bending roll with memory storage so operators can repeat bends accurately. With the operator control panel’s long extension cord, it’s easy to maneuver the controls to work from either side of the machine. The electrical cabinet uses standard electrical components that are always in stock in our warehouse for fast replacements when needed.

Features

-

Powered roll adjustment

-

Precision pinch roll adjustment

-

Top roll swing-out

-

Emergency trip line

-

Pedestal control

-

Quick roll adjustment

-

Roll position indicators

-

Crowned rolls

-

High torque gearbox

-

Low voltage push-button controls

Specifications

| Capacity | 10‘ x 1/4” Mild Steel @ 65000 PSI |

|---|---|

| Pre-Bend Capacity | 1/4” Mild Steel @ 65000 PSI |

| Top and Bottom Roll Diameter | 7.4”/7.5” (ends/middle) |

| Bending Roll Diameter | 6.67”/7.1” (ends/middle) |

| Speed | 19 FPM |

| Main Drive Motor | 5.5 HP Reduction Gear Drive |

| Adjustment Motor for bend roll position | 3 HP |

| Machine Length | 177” |

| Machine Width | 54” |

| Machine Height | 44” |

| Net Weight | 9,250 lbs. |

| Voltage | 220/440 Volts, 3 Phase |

Package includes

-

Heavy duty gear-motor drives top and bottom pinch rolls

-

Powered Bending Roll Adjustment and Manual Precision Pinch Roll Adjustment

-

Emergency Trip Line

-

Pedestal Control

-

Quick Roll Adjustment

-

Roll Position Indicators

-

Crowned Rolls

-

Low Voltage Push Button Controls

-

Machine is usually stocked with optional hydraulic swing-out feature for top roll

-

Machine is usually stocked with optional digital display with memory for position of bending roll

-

Machine is usually stocked with optional ability to tilt rolls, and blocker for making tapered cones

-

Machine is usually stocked with optional hardened rolls and black oxide coated.

What Our Experts Think

The U.S. Industrial Machinery Plate Roll (USR1025) is a high-capacity, heavy-duty machine designed for large-scale metal rolling. Here’s why it’s an industry favorite:

- Large Capacity: Rolls plates up to 10' in length and 1/4” thickness, making it perfect for larger projects.

- Initial Pinch Technology: Ensures precise, consistent rolling with greater material control from start to finish.

- Durable Build: Heavy-duty construction for extended use in tough industrial environments, ensuring durability and reliability.

- High Efficiency: Optimized for fast operations, reducing production time and material waste.

- Versatile Functionality: Ideal for bending and shaping plates in a variety of industrial applications, from manufacturing to construction.

- User-Friendly Controls: Easy adjustments and intuitive operation make it accessible to operators of all experience levels.

Q&A

Q: What is the U.S. Industrial Machinery Plate Roll USR1025?

A: The USR1025 is a 10' x 1/4" initial pinch plate roll, designed for high-capacity, precision rolling of thick metal plates.

Q: Which industries use the USR1025 Plate Roll?

A: It is commonly used in metal fabrication, construction, and manufacturing, especially for heavy-duty plate rolling and bending tasks.

Q: What materials can the USR1025 roll?

A: The USR1025 can handle various metals, including steel, aluminum, and other alloys up to 1/4" thick.

Q: How does the initial pinch design benefit the rolling process?

A: The initial pinch design improves control over the metal, ensuring accurate and uniform bends throughout the rolling operation.

Q: Is this machine suitable for large-scale industrial applications?

A: Yes, with its extended length and robust build, the USR1025 is perfect for high-volume and heavy-duty industrial operations.

Q: What advantages does the USR1025 offer in terms of productivity?

A: The machine’s efficiency, large capacity, and ease of operation reduce setup time and maximize output, ensuring high-quality results on large projects.

Maintenance Tips

- Daily Cleaning: Clean metal chips, dust, and debris from the machine after each use to prevent damage to surfaces and ensure smooth operation.

- Lubrication: Regularly lubricate all moving parts, including bearings, gears, and rollers, to reduce wear and ensure proper function.

- Roller Inspection: Check rollers for any signs of wear, cracks, or damage and clean them to prevent surface imperfections in rolled material.

- Alignment and Adjustment: Periodically check and adjust roller alignment to ensure uniform rolling and prevent distortion.

- Hydraulic System Maintenance (if applicable): Monitor hydraulic fluid levels and inspect hoses and components for leaks or wear.

- Drive System Check: Inspect belts, chains, and gears for proper tension and replace any worn or damaged parts.

- Tighten Fasteners: Periodically inspect and tighten bolts, nuts, and other fasteners to ensure stability during operation.

- Protective Covering: When the machine is not in use, cover it to protect it from dust, moisture, and other contaminants.

Related Products

- Choosing a selection results in a full page refresh.